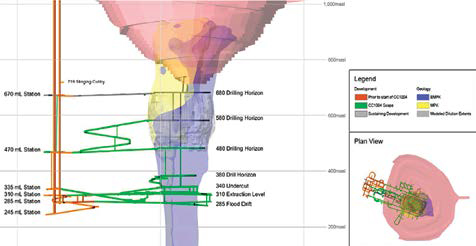

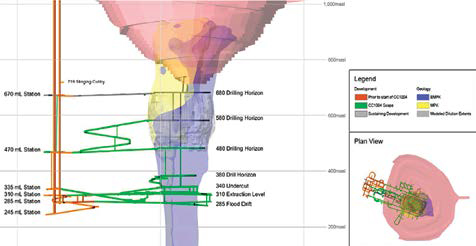

Karowe’s UGP will allow to access the kimberlite pipe at depth. (Graphic: Lucara)

Lucara Reports Significant Progress on Shaft Sinking Operations

The Karowe UGP will allow the mine to access the highest value portion of the Karowe orebody, with initial underground carat production predominantly from the eastern magmatic/pyroclastic kimberlite (south) unit. The project is expected to extend the mine life beyond 2040. The anticipated commencement of production from the underground operations is H1 2028. The company revised its forecast of costs at completion to $683 million (including contingency). As of September 30, 2024, capital expenditures of $353.5 million had been incurred and further capital commitments of $57.4 million had been made.

Open pit mining will continue until mid- 2025 and provide mill feed during this time. Stockpiled material should provide uninterrupted mill feed until 2027 when Karowe UGP development ore is scheduled to start offsetting stockpiles with high-grade ore from the underground development. Full scale underground production is planned for H1 2028. During Q3 2024, the UGP achieved a 12-month rolling total recordable injury frequency rate of 0.65. The UGP total recordable injury frequency rate of September 30, 2024 was 0.57. A total of $24.1 million was spent on the Karowe UGP development in Q3 2024.

Lucara said it completed the construction and pre-commissioning of the permanent bulk air coolers at the production shaft in July 2024. Construction and fabrication of the permanent man and materials winder continued during the quarter, representing the last major component for the permanent winders. The company commenced the adjudication and review of underground lateral development tender documents.

Advanced mining engineering with a focus on supporting shaft sinking, underground infrastructure engineering, finalizing drilling level plans and placed shaft steelwork orders topped the list of accomplishments in October 2024.

Some underground equipment, including an additional LHD for the production shaft station development, were calendared for Q4 2024. Major components of the underground crusher and dewatering pumps will be delivered to site. Detailed design and engineering of the underground mine infrastructure, drawbells and underground layout continues. The capital cost expenditure for the UGP in 2024 is expected to be up to $80 million.