New technologies from the top blasting solutions suppliers seek to optimize blasts for

improved productivity. (Photo: BME)

New Tech Improves Blast Outcomes

Advanced software helps users optimize blasts for improved fragmentation,

productivity and safety

By Jesse Morton, Technical Writer

Optimization System

Ups Productivity

Experts at Dyno Nobel reported the Delta

E2 blasting-optimization system

was used by a copper mine in the U.S. to

increase productivity and cut costs.

Previously, the mine was “running at a

24% P80 passing,” and was loading “different

products based on borehole wetness,”

said Jay Thorsness, field trials and operations

specialist. The strategy “presented

an inconsistent PF within the pattern and

inconsistent fragmentation of each blast.”

Switching to E2 allowed for custom

loading of each pattern as well as each

individual hole within a pattern based on

rock hardness developed within the preload

software,” he said.

Using the latest version of Differential Energy, the E2 system, allowed for wider patterns that “achieved a 33% or greater P80, with an increase from 27,000 metric tons/day (mt/d) to more than 36,000 mt/d on average,” he said. “Along with pattern expansion and density control, data has shown a significant production increase resulting in a substantial cost savings for the customer.”

E2 offers the “flexibility to custom load each pattern as well as custom load individual holes within a pattern according to geologic conditions and desired PF,” said Jeff Averett, senior manager, bulk products and delivery systems. “Everything can be done on software that is then loaded into the DynoLogix control system on the loading equipment.”

Thus, the system, which includes Titan Bulk Emulsion and the DynoLogix bulk-loading technology, “allows mining engineers to maintain full control of the blast-loading process,” he said. “It allows the application of explosives energy in a very controlled manner.” The system assimilates data from “smart drills, geologic models, or any other available information that quantifies the rock mass to optimize the energy in the blast,” Thorsness said.

“This is done using proprietary software that allows the engineer to easily define how energy is distributed within the blast and even within individual boreholes,” he said. “The easy-to-use desktop software is used to create loading instructions for the bulk truck.” The operator designates which hole is being loaded and the depth. “The truck will make any needed adjustments and log dozens of data points about the actual loading conditions that can be sent back to the software to track performance of the loading process,” he said.

Blasting optimized by the E2 system can contribute to increased productivity. E2 provides the opportunity to custom load by density in a given range within the borehole,” Averett said. “The desired density aligns to specific ranges of rock hardness to maximize rock fracture in each of the segments within the borehole,” he said. “Up to six different density segments can be loaded in a single borehole.” With a carrying capacity of 19,000 kg, jumbo-sized trucks pump at a rate of 800 kg/min, “which maximizes load time per load on the pattern and minimizes reload time.”

Optimized blasting can also translate to lower costs. When loading emulsion “the end-of-hose gassing technology allows very quick changes to the energy profile in the borehole,” Averett said. “This helps reduce overall drill and blast costs by potentially reducing drilling costs and explosives usage when ground conditions permit,” he said. “The product undergoes additional refinement on the bulk truck that improves explosive efficiency and energy yield.”

Beyond being used to optimize blasts to improve productivity, the system can be used to help optimize safety. “Safety is always our highest priority,” Thorsness said. “Titan Differential Energy is manufactured, transported, and stored on site as an oxidizer, greatly reducing any unplanned events,” he said. “It only becomes a blasting agent during the loading process during the final mix at the end of the loading hose.”

The end-of-hose gassing technology ensures “the emulsion is not sensitized until it leaves the loading hose and is placed in the borehole,” he said. “The bulk trucks also have an advanced safety shutdown system that monitors several parameters on the bulk truck and will stop loading if an unsafe condition is detected.”

Optimization of energy placement may also reduce flyrock. Beyond that, the system can also be used to help with compliance to regulations on leaching. “The Titan bulk emulsion product line, which is the foundation of the Differential Energy System, significantly reduces NOx and nitrate leaching in groundwater,” Thorsness said.

Research and development for the Differential Energy system began in the early 2000s. “The development of our automated gassing system in the mid- 2000s and then the end-of-hose gassing system in the late 2000s allowed finer control of the gassing process,” Averett said. “The development of our proprietary control-and-delivery system allowed significant improvements in the accuracy of the gassing process and quality of product delivered,” he said. “In 2018, the ?E2 system was released, and it allows the system to use available data on geologic conditions to guide loading and placement of energy within each borehole.”

Rigs Integrate Optimization

System

Separately, an autonomous rotary drill

rig expert at Sandvik said customer

feedback on iSeries rig integration with

Dyno Nobel’s blast optimization solution

furthers other continuing horizontal integration

projects.

“Ultimately, user experience has been

positive using the solution,” said Demetre

Harris, product line manager, automation

and rotary drills. “And working together

with Dyno Nobel on this integration gives

our customers the potential for optimal

blasts, which can result in lower blasting

costs and better fragmentation.”

The iSeries control platform, DRi, was purpose-built for integration with current and future technologies and advanced control solutions. In this case, Dyno Nobel’s blast optimization software solution, E2, automatically accesses and uses measure while drilling (MWD) data. That data is captured at 5-cm intervals by iSeries rigs: the DR410i, DR412i, DR413i, DR416i, and Leopard DI650i drilling rigs. The data is transmitted to the MySandvik OnSite or Productivity solutions.

The cooperation between the two suppliers on horizontal integration was driven mostly by shared priorities. “This integration with Dyno Nobel was done first because of a visionary customer and a great collaborator in Dyno Nobel,” Harris said. “We all saw a need and worked together to deliver a solution,” he said. “Just as our APIs are available to all of our customers, Dyno Nobel’s solutions are available to all of their customers.” Sandvik’s iSeries rigs have multiple active integration options. And, for Sandvik, the collaboration with Dyno Nobel for horizontal integration is one of many. “We have active onboard collaborations with fleet management systems to provide machine positioning, status, and productivity information,” Harris said. “In addition, we are currently working with a customer regarding an integration to improve their blasting efficiency.”

Sandvik iSeries rigs support “thirdparty planning solutions pulling information to assist customers with planned versus actual variance tracking,” he said. “We have found over the years that, with each new customer, a new opportunity for integration and improving efficiency is born.”

Therefore, Sandvik is seeking similar partnerships on horizontal integration with other blasting solutions suppliers. “Sandvik’s ultimate goal is to provide solutions that create value for the mining industry,” Harris said. “If we have a customer with a different blasting supplier and each party is willing to collaborate, let’s work together to create a fantastic solution,” he said. “Whether it is for blasting improvements, operational efficiency, or preventive rig health initiatives, Sandvik is always willing to sit down and discuss solutions with customers and third-party solution providers.” Through such partnerships, “we are looking at developing many solutions to revolutionize day-to-day operations.”

Modelling Software Predicts

Outcomes

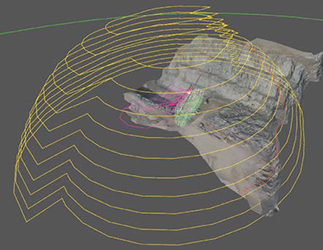

An expert at Austin Powder said Paradigm

software is uniquely a pure-play

drill-and-blast modeling software solution.

“Paradigm software is completely

focused on the drilling and blasting

phase of mining, whereas other offerings

may include some blast design and analysis

features,” said Alan Romphf, global

blast engineering manager.

“Paradigm is a state-of-the-art blast design and engineering modeling package,” he said. “It can be used for everything from complicated blast designs where outcomes are critical to simple blast timing designs and everything in between.” Paradigm can be used during the design phase “to predict and analyze various blasting outcomes such as flyrock, vibration, drilling accuracy, fragmentation, and wall damage,” Romphf said. “Using Paradigm, mining engineers can significantly enhance their ability to design blasts, improving operational efficiency, reducing costs, and creating safer working conditions.”

The models can be used to improve safety. “The models within Paradigm are field-proven and are continually being reviewed and refined,” Romphf said. “Paradigm’s Sweetspot and Vibration footprint models have been used to extract previously compliance-locked resources and reduce environmental impacts from blasting worldwide.” The flyrock model can be used to “assess the potential range of flyrock and the probability of something within a specified area being struck by flyrock,” he said. “Paradigm’s flyrock model improves safety by allowing engineers to better determine clearance areas before firing the blast, considering the blast design and terrain effects.”

The Sweetspot vibration model “uses the principle of wave superposition with some proprietary twists to simulate blast vibration outcomes,” Romphf said. “Sweetspot permits users to run millions of timing iterations to determine how to sequence the firing of blastholes to minimize how a blast affects or is perceived by people at locations within or surrounding a mine.” Paradigm can import and export blast patterns. “Blast patterns can be created within polygons, smoothing curved rows into straight rows, in rectangular or staggered grids, or in free form,” he said. “Patterns generated with Paradigm can be exported to the IREDES format which is compatible with many types of smart drilling equipment.”

Paradigm has a “relatively shallow learning curve,” he said, and it offers a range of benefits. Topping the list is improved production and increased revenue. “A blast outside of specifications can slow down production or be outright disruptive to a mining operation,” Romphf said. “Overly large material may be difficult to handle or may block a primary crusher, while material that is too fine may also be detrimental to downstream processing,” he said. “Designing the best possible blast using Paradigm will help ensure the right material is delivered to the crusher.”

Optimized crushing translates to improved production and operational efficiency. “By modeling blast outcomes during the design phase of blasting, Paradigm also helps mining customers reduce costs,” Romphf said. “This efficiency translates into improved profitability and enhanced investor confidence.” By helping to reduce risks involved in blasting, Paradigm assists customers in complying with regulations and satisfying stakeholders. “External stakeholders often perceive blasting as risky or dangerous,” Romphf said. “Designing blasts to minimize perception and environmental impact can help a mine maintain its social license to operate in the community,” he said. “A blast designed to provide the right gradation of fragmented material with minimized vibration and overpressure perception offsite is a win-win scenario for both the mine and external stakeholders.”

Paradigm empowers the miner with data that can be used to make critical decisions that can improve operational performance. The same data can be used to explain and illustrate those decisions to stakeholders and investors. “The ability to make data-driven decisions based on simulations and analysis enhances investor confidence in the company’s management and operational capabilities,” Romphf said. “Overall, Austin Powder’s Paradigm software can improve safety and regulatory compliance and enhance operational efficiency, ultimately bolstering investor confidence.”

Paradigm was first developed by Igneous Tech, which was acquired in 2023 by Austin Powder. “Many of the design tools and models within Paradigm were specified by Dr. Cameron McKenzie of Blastechnology Australia,” he said. “Austin Powder’s global team of technical service experts have honed and validated the tools and models found within Paradigm.”

More recently, the software system and E*STAR electric detonators were trialed by an open-pit iron ore mine in Sweden that wanted a solution to improve fragmentation quality and that offered more control. “The typical iron ore blast in this mine uses the following parameters: hole depth is 15 m; hole diameter is 165 mm; hole depths vary from 10 to 20 m; burden is 4.7 m; and spacing is 5.0 m,” Austin Powder said. “The typical, nonelectric blast was done with stemming lengths of 3.3 m.”.

The miner aspired to “be one of the most innovative and high-tech mining companies,” which “is the main reason why they are using Austin Powder E*STAR detonators,” the supplier said. “The mine requested a separation of ore and waste, and control of muckpile movement.” The trial blasts were planned using “a blast-design modeling software, Blasting Solutions, and later, using Paradigm,” Austin Powder said. “Based on inputs and software analysis, best timing (inter- hole and inter-row delay) was calculated and recommended.”

The electric detonators and Paradigm delivered superior results compared to the preexisting solutions. Those results included better initiation control, control of muck pile movement, and improved dilution control. “Using E*STAR electronic detonators with optimized timing focused on rock properties and blast conditions allowed the mine to increase the stemming length from 3.3 m to 4.3 m,” Austin Powder said. “That resulted in saving 25 to 28 kg of bulk emulsion 70/30, which is 9% of the average hole amount.”

The results exemplify the capabilities of Paradigm and other solutions by Austin Powder, Romphf said. “And developing new features and improvements to the Paradigm software is ongoing,” he said. With the phrase ‘Innovation that matters’ in mind, Austin Powder strives to ensure that the tools in the customer’s blast design toolbox remain the sharpest.”

System for UG Gives

Enhanced Control

BME announced the AXXIS Centralized

Electronic Blasting System (CEBS) for underground.

The digital detonator system

augments AXXIS Titanium software for

deep-hole operations and AXXIS Silver

software for smaller blasting operations.

A blasting systems expert at BME

said CEBS uses IoT technology to capture

and use data within the software

suite. It allows “improved safety, enhanced

control, increased accuracy, and

dual communications, which are fundamental

for underground operations,” said

Nishen Hariparsad, general manager of

technology and marketing.

The logger communicates with the AXXIS CEBS Blasting Box, situated underground, which aligns the timing design with the blast design. The blasting box communicates with the blast controller, running Blastmap Underground design software, on the surface. The controller manages the entire process, and monitors and reports all data and activity. AXXIS CEBS is designed for use on almost any underground network. “The system has been designed to feed into standard network architecture without the need of running new cabling, without the need of new architecture or alternate communication channels,” Hariparsad said.

The system uses AXXIS Silver electronic delay detonators. “The reason we do this is so the integrity of the blast is maintained. It ensures the quality of the blast outcome,” he said. “We know the technology the AXXIS detonator holds and the benefits it provides.” The primary benefits offered are accuracy, efficiency, safety and ease of use. “That is what sets it apart from other systems in the underground market,” Hariparsad said. “The system is designed around precision, accuracy and efficiency,” he said. “It provides our customers with guarantees on blast outcomes.”

That means blasting becomes more predictable. “If they have a good understanding of predictable blast outcomes, they can better manage their entire value chain,” Hariparsad said. “That alone drives efficiency in the entire process, drives costs down, offers safety benefits and, through the value chain, improves yield,” he said. “That is why an electronic blasting system that is fully programmable that can deliver accuracy and precision delivers not just on blast outcomes but on customer expectations through the value chain.” Trials for AXXIS CEBS have resulted in numerous customers eager to deploy the system, he said. In trials there were “zero misfires, and zero incidents.” The time savings alone “make a success story for us.” Customers are switching from alternate systems because they “see the benefits provided in terms of ease of use, improved safety and other value adds.”

Study Says Drilling AI

Ups Productivity

A white paper from Hexagon said field

trials of its autonomous blasthole drilling system gave substantial productivity

gains while cutting costs and reducing

operator training to a mere 15 minutes.

“Hexagon Drill Assist uses artificial intelligence

to increase drill productivity by

42% over a leading OEM drill automation

system,” said Curtis Stacy, senior product

manager, autonomous drills, Hexagon’s

Mining division.

Originally developed by Phoenix Drill Control before it was acquired by Hexagon, OEM-agnostic Drill Assist “coexists with the OEM control system and leverages any existing sensors on the drill rig,” the paper said. “When not in use, the Hexagon Drill Assist technology platform is disconnected from the OEM control system.” It can be installed in roughly a work week.

The AI also generates critical data. “The solution’s algorithms were created to calculate the hardness of the ground being drilled,” the paper said. “All relevant sensors are monitored simultaneously, and rules are applied to determine a hardness value.” The system was first tried on a lowtech and then on a high-tech rig. On both, it delivered similar results and benefits. Topping the list were “increased productivity, lowered training requirements for new operators, reduced technology maintenance requirements” and “added value through data generated during the drilling process,” the paper said. “Cost of drilling was reduced by 30%.”

New operator training was drastically reduced, “empowering trainees to perform at expert production levels when they first start in operations,” the paper said. “By eliminating the requirement for the operator to ‘estimate’ and enter drill site parameters prior to commencing drilling on each hole, new operator training for the drilling process was reduced to just 15 minutes for each new operator,” Hexagon reported. “Hexagon achieves this minimal training time by limiting the amount of interaction required for an operator to use the technology to just one button.”

The next study could look at how Drill Assist can help optimize blasting. “Preliminary results suggest that the use of AI in the drill algorithm is making the MWD data more consistent and more reliable,” Stacy said. “Gains in this area of study will impact operating costs, from the mine to the mill.” New tests are expected that will trial the solution on additional makes and models.