Some mines could reduce processing costs by 30% to 40% by using sorting systems to pre-concentrate the feed.

(Photo: Tomra Mining)

Screening and Sorting Systems

Improve Plant Processing Efficiencies

Rejecting waste from processing streams reduces the consumption of water,

energy and the amount of tailings

By Steve Fiscor, Editor-in-Chief

Sorting systems classify rock by using methods other than mechanical screening. More recently, sorters have gained in popularity. They use different techniques to characterize the feed, distinguishing rock as either mineralized or waste. The sorters prevent a portion of the feed from entering the plant’s processing system and, in some cases, that stream can be recycled, redirected to the pit or stowed underground.

In some applications, sorting systems and screening machines work together. The screen deck gives the sorter the opportunity to assess the feed and make decisions. Like everything else these days, sorting systems can make decisions in a split second, which influences downstream performance of the plant.

The milling process accounts for roughly 6% of a mine’s operating expense. It uses considerable amounts of water and energy. With some types of ores, sorting systems could reduce those inputs, which lowers operating costs and improves the plant’s environmental footprint. If the system can pre-concentrate feed before it enters the plant, the volume of tailings will also be reduced. These are important factors that contribute to the sustainability of modern mining operations.

Sorting Ore Streams

Effectively

Sorting systems have created a paradigm

shift for mineral processing systems.

Over the years, these systems

have steadily improved as far as accuracy

and capacity. With the mining industry’s

constant pursuit of cost savings

combined with sustainability concerns,

they offer an effective solution for some

ores. Today, engineering firms are applying

the use of sorting systems in feasibility

studies and factoring their contribution

into the economics of tomorrow’s greenfield

operations.

“Imagine a mine that discovered it could reduce one-half of the load to the mill circuit, they would be very excited,” said Fernando Romero-Lage, sales manager for South America for Tomra Mining. “If we can displace 40% of the feed, the plant consumes less water, less electricity, less reagents, and on top of that they could see a tailings reduction of 35% to 50%.”

While Romero-Lage believes a mine could save probably 30%-40% on processing costs using sorting systems, he also acknowledges that it cannot be used for all mining applications. With certain geologic formations, such as oxide caps and porphyries, the mineralization tends to be highly disseminated and may be more difficult to identify. “Sorting systems work well with heterogeneous materials like sulphides, polymetallics, and massive deposits,” Romero-Lage said.

Tomra Mining’s business has doubled in the last two years and Romero-Lage attributes it to the return on investment. “The payback on a sorter sometimes can be less than a month,” he said. “The higher the value of the recovered commodity, the bigger the benefit. The savings for some gold mines are incredible.” Sorting systems also return inert material to the earth at a manageable size. The rejected rock usually has no acid footprint, which means it could be used as road base or a construction aggregate.

Today’s sorting systems can do things that simply were not possible 20 years ago, thanks in large part to the improved processor speeds, which allow decisions to be made much more quickly. The computers can access and analyze several algorithms, which has improved accuracy and processing capacities dramatically. The capacity of the sorting system is contingent on the size fraction of the feed. It will analyze every specimen that is presented to it and finer particle size distributions present more specimens.

The sorters could be placed after primary crushers underground or between the secondary and tertiary crushing stages on the surface. Ideally, the system would be used with a horizontal screen with a relatively low material velocity (35 to 55 feet per minute), which increases the probability of separation. An inclined screen would be unsuitable as it relies on stratification, and may be inefficient in removing the near size material.

Intelligent sorting programs allow the users to change the plant’s cut point in seconds to adapt to a changing plant feed. “We work with the processing plant to design a set of recipes,” Romero-Lage said. “If the concentration increases and the plant wants to harvest high grade material, instead of rejecting low-grade material, the programs can be reversed. When the ore changes, the system rescans the ore and targets the stream differently. Sometimes a mine will encounter an undersized material that becomes troublesome. It’s barren, and it’s probably hard and abrasive rock, and it can now be redirected.”

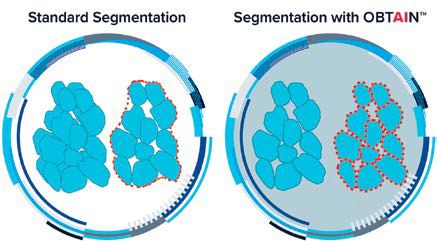

Taking the technology one step further, Tomra Mining recently launched Obtain. “Obtain is a new model that will use artificial intelligence (AI) and machine learning to make a better characterization of the feed that is presented to the sorter,” Romero-Lage said. “In a situation where two particles that are too close together, the current system would see that as a single rock and reject it. Using Obtain, results are more independent of the capacity. As a result, the throughput can be increased, and in many cases, it can be doubled.

“The module teaches the machine based on the application,” Romero-Lage said. “Variables are introduced, and the machine learns from those variables and adjusts. With AI, we are going to map a lot more of what’s happening in the machine, so then we can make even more decisions more quickly.”

The advantage is that feed coverage on the belt or screen deck could be increased considerably, which would obviously increase the overall capacity of the machine. In addition, accuracy and recovery will also improve.

“We have been testing this system for about two years, and we are seeing a huge difference using the AI module,” Romero-Lage said. “In some cases, we could increase the capacity to 400 tph from 250 tph. With AI, we’ll be able to attain 70% more capacity and the recovery numbers will increase considerably as well.”

Romero-Lage said he gets excited when he thinks about how Tomra Mining will help minimize the impact of mining on the world moving forward. He sees millions and millions of tons of waste today that can be reduced by 30%-50%. “It is not just the money that the mines are going to save, but the fact that they can actually be proud that they’re doing something to minimize the impact to the environment,” he said.

Advanced Screening

Systems

When it comes to screening machines,

Weir Minerals supplies some of the largest

screens for mining applications. The company

recently introduced the Enduron Elite

screen, a double-deck banana screen, available in a range of sizes with the largest

weighing in at close to 50 metric tons (mt)

with a deck that measures 4.3- x 9.7-m.

“These are some of the biggest screens on the market, ideally suited to large hard rock mining operations,” said Corné Kleyn, global product manager-vibrating screens for Weir. “We’ve spent years designing and developing these high throughput machines for highly abrasive applications to fill an important gap in the market.”

These screens have been developed to be fed by Weir’s Enduron HPGR. Weir has been on a mission to transform the traditional flowsheet, replacing tumbling mills with HPGRs and vertical stirred mills, which the company believes could reduce energy consumption by 40%. The Enduron Elite screen would play a vital role in this flowsheet. They could also be used in tertiary and secondary screening applications, as well as desliming iron ore fines.

The Enduron Elite screens come equipped with polyurethane panels, which allows the machine to achieve the required cut size. Rubber panels are also available, depending on the application. Screens, in any mining application, are subjected to very high levels of stress, so good, rigorous maintenance procedures are essential to ensuring they perform effectively for the duration of their life, Kleyn explained. “When it comes to maintenance, it’s very important to continuously inspect and monitor liners,” Kleyn said. “When the rubber wears away, and the material comes into direct contact with steel, the likelihood of screen failure increases significantly. Put simply, if you add wear and corrosion to fatigue, then you’re likely to have problems. So, it’s vital that the wear protection remains intact.”

The other major important area to monitor is the health of the exciters and bearings. The exciters on the Enduron Elite screens are huge, so monitoring the temperature of the bearings and changing the oil regularly is very important, Kleyn explained. Maintenance procedures should include making sure the springs remain clean and free of debris.

“Our screens can also be digitally enabled, providing the operator with greater visibility of equipment health and performance, as well as providing the opportunity for process optimization,” Kleyn said. “Weir Digital monitors bearing health, temperature, vibrations, acceleration, throw angle and overall screen health.”

“Weir has assembled a team with more than 80 years of collective screen design experience, and they developed this new Enduron Elite range of screens,” Kleyn said. “We’re really excited to see this product come to market.”

The Weir screen team is also supported by Weir Technology Hubs (WTH), which allows them to test material and select the most suitable machine based on real test data. They are essentially partnering with mining companies on flowsheet development. Based in Venlo, the Netherlands, WTH includes an HPGR and two STM vertical stirred mills, which allows Weir to provide proof of concept for both greenfield and brownfield projects looking to explore the viability of implementing that transformational flowsheet.

Weir has an extensive service and support network, spread across 70 countries, and strategically located in all the major mining regions, Kleyn explained. “This allows us to be close to our customers – not just geographically, but also in terms of the relationships we have with them. We work with them to understand their challenges and develop and implement solutions to optimize their equipment and processes.”

GK Expands Its Facilities

General Kinematics (GK) offers a broad

line of material handling products including

brute force and Two-Mass screening machines.

The company recently reported its

customers are seeing throughput improve

by up to a factor of two with its STM Two-

Mass screens, all while fitting in the same

footprint and using two-thirds less energy.

The STM Two-Mass screens rely on a natural frequency design. The company explains that as load responsive and capable of longer material retention times to work the material more, which means more screening can be accomplished in the same footprint as a brute force machine. GK also said the dual in-board vibratory motors eliminate belts, shafts, and bearings. The machine’s modular design uses a center spline to significantly increase structural integrity and allows for easy assembly and disassembly for quick transport and installation.

During October GK celebrated the completion of a 42,000-ft2 expansion of its primary manufacturing space. The new area includes high bay ceilings for 80-ton cranes, and additional space for manufacturing large equipment. Including the new addition, GK’s facility in Crystal Lake, Illinois, USA, now spans 262,000 ft2.

Scalping Large Feed Sizes

Superior Industries recently added another

advancement to its lineup of Guardian

Horizontal Screens with a new heavy

duty scalping model. The new HD scalping

screen handles a maximum feed size

of 18-in. (457 mm). This surpasses its

medium-duty predecessor, which maxes

out at 14-in. (355 mm).

The HD screen is equipped with a perforated top deck, or punch plate, made of heavy-duty 3/4-in. abrasion-resistant steel. A slight slope facilitates the movement of feed material for efficient screening. Superior manufactures more than a dozen models of its Guardian Horizontal Screen series in Columbus, Nebraska. Horizontal screens are available in two, three, or four-deck configurations and footprints from 5- x 16-ft to 8- x 20-ft.