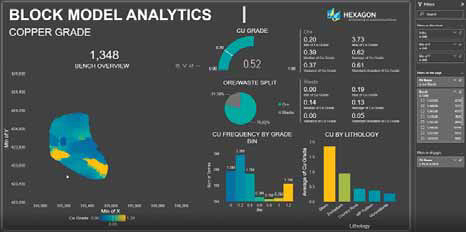

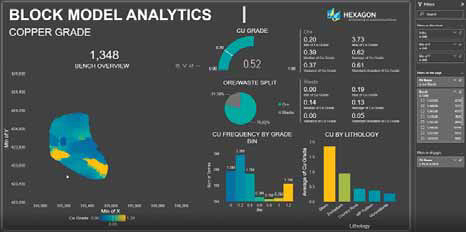

The MinePlan Block Model Manager analyzes data and improves visualization. (Image: Hexagon)

Emerging Trends With Mine

Planning Systems

Using inputs from more data sources and cloud-based solutions,

mine planners are generating field-executable plans more efficiently

By Steve Fiscor, Editor-in-Chief

While AI steals the headlines, there are two other trends that are also emerging: cloud-based solutions and interoperability. Cloud-based solutions allow mine planners, geologists, and engineers to interact with the latest data sets remotely. In addition to remote collaboration, cloudbased systems offer enormous computational advantages, which are becoming a requirement with today’s large data sets. Interoperability allows a platform to use other applications to import data into the model. These applications could range from geologic data from the drills to Lidar data from the drones to financial tools. Mine planners can use these tools to access more data to test and optimize various mining scenarios. The more successful systems will work with other systems seamlessly.

Another improvement taking place across the board is improved block model visualization. As these systems become more sophisticated and computations improve, they can present data in a more useful manner. Will this advancing technology replace the geologist or the mine engineer? No. It makes the aspects of their job that are repetitive and time consuming quicker, allowing them to spend their valuable time and skills on more critical tasks. The improvements in mine planning software will hopefully lead to more field executable mine plans and close the gap between the theoretical world and actual job of extracting ore efficiently.

The Evolving Landscape

for Mine Planning

In the past year or so, AI and machine

learning have attracted a lot of interest

in every aspect of life, including mining,

explained Payam Koohi, director, customer

success – MinePlan for Hexagon’s

Mining division. Hexagon has a full suite

of mine planning technology in support of

geologists and engineers across evaluation,

planning, and design. “A decade

or so ago, the trend was Big Data,” Koohi

said. “Miners were collecting large

amounts of data from many sources. The

amount of data that they were collecting

exploded. Then the industry realized that

data itself is not as valuable as extracting

insights from it to facilitate better decision

making. They needed more advanced

tools to quickly analyze that data.”

Similarly, mine planners today are handling larger data sets, and they want to examine more complex scenarios. The integration of AI and machine learning with mine planning tools will enable mine engineers and geologists to use these tools to analyze that data and extract information, gain insights, and make better decisions. “AI and machine learning are the biggest trends in the market at the moment, and it’s in the very early stages, but it will become bigger and bigger as we move forward,” Koohi said. “In the next five to 10 years, machine learning will play a significant role in mine planning software and mine planning in general.”

The other thing that is fairly new in mine planning, Koohi explained, is cloudbased solutions. “When we talk about cloud-based solutions, it’s basically from two different perspectives,” Koohi said. “One is about multiple users accessing the most up-to-date project files and software on the cloud and collaborating with each other from any location.” The second aspect of cloud-based solutions involves the data sets, which are becoming quite large, and projects, which are becoming more complex. “The speed of cloud-based computation allows mine planners to examine multiple scenarios of complex projects,” Koohi said. “This can no longer be accomplished effectively with a laptop or a single computer.”

Interoperability, or the way one piece of software can operate with other applications or hardware solutions, is another important emerging development. Having access to integrated solutions, Koohi explained, allows mine planners to look at the problem from various perspectives and aspects. “It’s unlikely that they could find these advantages with one piece of software or one tool,” Koohi said. “You need to have interoperability with a range of technologies and solutions.”

The interface, or user friendliness, of mine planning software is also important. A growing generational gap in the mining industry has been identified. “We have very experienced miners who have been in the business for decades,” Koohi said. “We also need to attract more young people into the mining profession to sustain the business. These younger people work with mobile apps, so the interfaces for mine planning software will need to evolve and improve. We will need to adjust and adapt to these trends to have more user-friendly interfaces that can address the needs of the experienced people in the field as well as the needs of the next generation.”

Combining Visualization

With Optimization

Modern mine planning systems can also

help mining companies achieve sustainability

targets.

The MinePlan Schedule Optimizer

generates the best sequence of mining

based on the constraints that are defined

for it. Planners can set as many constraints

as they want, Koohi explained.

“When they optimize the mining sequence,

the tool tells them where to mine

first and provides a mining sequence that

maximizes the net present value for the

project. A big consideration with schedule

optimization is the cost of haulage,

which represents 40% to 50% of operating

costs. Optimizing the fleet size and

targeting the fuel burn specifically improves

the economics of the project and

reduces the carbon footprint.”

“Visualization has always been a very big part of our work with block models,” Koohi said. “Improved visualization capabilities will allow users to see more realistic representations of the mines. It will help them to better understand the geological features of their mine, and the challenges, which leads to better decision-making.”

Traditionally, most block models were file-based, but the MinePlan Block Model Manager moves that file-based system to a server or a cloud-based system. “The block is a single source of truth for the mine,” Koohi said. “The model is the most important piece of the mine planning process because everything in mine planning is based on that.” “Data management, analysis and visualization are three components that must work together,” Koohi said.

All of these developments are great, but nothing can replace the expertise that the geologists and mining engineers bring to the table, Koohi explained. “These tools allow geologists and engineers to do their jobs better,” Koohi said. “With traditional methods, for example, geologists had to import drill hole data and then build the geological models cross section by cross section, drawing polygons around intervals of the drill holes. Depending on the complexity of the deposit, this project would take weeks or even months just for one scenario or one interpretation of the deposit.”

Today, that same geologist can generate a geological model in one or two days, using implicit modeling techniques. “It’s a huge time saver for the engineers and geologists, so they have more time to apply their skills to investigating three or four different scenarios.” If an anomaly is identified, it won’t take a month to recreate the model.

Koohi said seeing the wide range of technologies emerge in this field is exciting. “Add that to Hexagon’s vision of the Power of One which seeks to bring together solutions across the life of mine, such as blasting tools, fleet management systems, safety solutions, etc., to provide holistic solutions for better use of data in decision-making, profitability, and sustainability,” Koohi said. “We are focused on a fully integrated system that will revolutionize the mining business.”

Improving Pit Design

Carlson Software will soon roll out Carlson

2024. “We are completing our beta

testing,” said Tyler Faulkner, P.E., sales

and support, Carlson Software. “We perform

internal testing, but then we open it

up to some of our users that have expressed

an interest in helping us test the

new version. We are aiming for the end

of September for the release of Carlson

2024, but that’s always dependent on

the type of feedback we get during the

beta testing.”

Among the many improvements made during the last year, Carlson users can expect two major improvements: a new routine for pit design and a new format for block modeling. “The new routine takes a different approach to pit design,” Faulkner said. “The old method depended heavily on the surface files, which is susceptible to file size that created some complications, whereas the new method is based on linework. In one sense, it’s more simplistic, and that will make it easier to edit, modify and merge with existing ground surfaces. We also expect it to be more dynamic.”

The traditional Carlson block models have been different from the other systems available on the market, as they are based on a stack of grid files. “Grids really have been our bread and butter,” Faulkner said. “Our existing .blk files are a series of grid files that behave like blocks. It had some inherent limitations, but we are now working on an IJK-based block model where each block is not bound by the limitations of a grid. This will open doors for our users in regards to block modeling.”

All deposits and mines have site specific considerations and Carlson has designed its software so that it’s customizable. “The way that we develop the program is largely dependent on the requests that we get from users,” Faulkner said. “For example, the new pit design routine was developed from feedback we received on the existing routine.”

Faulkner said he also sees the benefits of AI, especially in a supporting role. One area is quickly formatting data. That’s becoming a huge challenge, especially when a mine uses a drone to collect 15 million points for a 10-acre pit, Faulkner explained. “Do you really need 15 million points?” Faulkner asked. “Sometimes planning suffers from having too much information that’s not necessarily helpful. Many users could could cut their data set in half without significantly impacting the final topography model.”

Another important service that comes with Carlson Software is free tech support. “If the mine planners have a question, they call us,” Faulkner said. “When users call our office, a live person answers, and they don’t have a script. It’s just ‘How can we help?’” Faulkner said he frequently moves the conversation to a web-based meeting, to simplify communications. If it turns out to be more of a complex troubleshooting task, he will ask for the information needed to repeat the problem and will then follow up with a solution. He said he gets excited about creative problem solving and finding new solutions.

Applications for Open-pit

and Underground Mining

Carlson 2024 will have hundreds of improvements,

which will coincide with

the newest version of AutoCAD. “We

have been reorganizing and updating

our block modeling and it will be more

standardized with compatible features

for hard rock applications,” said Grant

Wenker, vice president and director of

mining, Carlson Software. “The other big

routine that we’re adding is a new open

pit design tool, the Pit Master, which will

be able to perform more advanced designs

quickly with roads and ramps.” To

make these improvements, Carlson has

hired new programmers and developers

with hard rock experience.

“As we move into block modeling, it will improve what we are able to offer hard rock mines,” Wenker said. “We are implementing it for both open-pit and underground mining applications. We will be able to model stopes and block cave mining. We were never able to accomplish that well using surface files in AutoCAD.”

Carlson offers a full suite of mining software. It has applications for blasting and haul cycle analysis. The scheduling feature can link the dump schedule with pit advance. “If a mine is hauling waste, or even ore, they can control and schedule where that material will be placed or stockpiled,” Wenker said. “Planners can generate an animation of the trucks traveling back and forth on all the routes.”

Wenker said he is impressed with the rapid pace of technological development. “The mining industry is doing more work with drones and point clouds,” he said. “A few years ago, mines were experimenting with drones and today many of them have a whole fleet of drones. These drones are now able to carry LIDAR packages that capture large amounts of data and save time.”

The pit design software considers various parameters such as the highwall angle, bench width and height, as well as haul road and ramp design. “Our products are fairly well-rounded compared to others because we have a full civil and survey module,” Wenker said. “It allows engineers to design and build anything from a two-lane dirt road to a four-lane freeway.”

Carlson also offers supporting software for hydrology, GIS, point cloud management, etc. “These are the different modules that the mine engineer needs,” Wenker said. “They don’t just buy a geology or a mining module. They usually purchase the entire suite that includes everything.”

As an example, Blast OPS is a standalone package where planners use point clouds to plot a bench, design a blast pattern, lay out it on the bench, load the holes and enter the timing sequence. “Using the software, planners can plot the holes so that they are drilled in the best location at the correct angle and depth,” Wenker said. “It also analyzes the burden to eliminate dead-pressing and reduce flyrock. If everything looks good, then you just click a button and upload it to the drill and then the drill navigates to each hole and drills it.”

Including the large quarries, Carlson has installed hundreds of systems. “These applications have become industry standards to some extent,” Wenker said. Many mining companies maintain an open purchase order and, when they need a license, they just order another license. “They don’t have to go through this huge approval process,” Wenker said. “That goes for software and hardware too.”

Wenker said one of the big misconceptions that he encounters is that, when the mines see Carlson’s affordable price, they don’t think the system is as capable as some of the more expensive systems that are currently available. “That’s a hurdle we have to overcome,” Wenker said. “We could raise our prices, but we also sell to many small consulting firms that can’t afford a big software package.”

Most of Carlson Software’s operations are based out of their headquarters in Maysville, Kentucky, USA. Some of the company’s programmers work remotely or out of the company’s Boston office, where they can tap into the local universities, like MIT and Harvard.