An untreated mine haul road. Fugitive dust has resulted in reduced

visibility. (Photo: Bind-X)

How to Deal With Fugitive Mine Dust

Dust control strategies are evolving for more effective suppression and protection, as well

as the elimination of particles at the source. We explore some of the latest solutions.

By Carly Leonida, European Editor

Steve Paulson, Director, Global Mining Marketing for Nalco Water, an Ecolab Company, explained: “Traditional dust control methods can be water intensive, which can be costly and challenging in water-stressed regions. Further, dust from material handling operations or stockpiles can pose significant health and safety hazards to mining personnel and the surrounding community. Fugitive dust particles can be inhaled, potentially leading to health issues. They can also lead to reduced visibility on roads, create challenges with air quality, particle runoff and more. Mine operators are looking for solutions that help them to effectively reduce dust while minimizing water use and cost.”

The use of chemical solutions in dust control programs can help to maximize the effectiveness of each application, allowing operators to use less water while still suppressing dust particles effectively. Nalco Water estimates that up to 60% of water used for road dust control can be lost to evaporation and run-off in harsh conditions. Chemical solutions can help the water penetrate solids more effectively so that less water can be applied. For instance, surfactant-based products help optimize the surface tension of the water, creating smaller droplets that impact a greater surface area. As a result, the product can penetrate deep into the bulk solids to minimize evaporation and run-off.

Nalco Water’s portfolio of dust control solutions includes foam-based products, surface tension reducers, binders, tackifiers, and humectants (based on the application area). Each solution combines innovative chemistry with material handling expertise to address customer’s unique operational challenges and requirements. In one example, Nalco Water helped a global mining company to develop a dust control program that effectively suppressed haul-road dust at its operations while minimizing water use and climate impacts. By implementing Nalco’s HAULAGE- DC solution, the customer reduced the number of water spray trucks operating daily from 13 to three, which led to a water saving of 400 cubic meters per day, fuel savings of 44,000 liters per year, and carbon emissions savings of 116,000 kilograms per year. The solution delivered more than US$1.5 million in cost savings.

Incorporating Biological

Solutions

Over the past decade, the transition towards

more sustainable best practices

has seen a widening in focus from conventional

dust control products such

as water alone, polymers and bitumen

emulsions to biological products from

natural raw materials as well.

Martin Spitznagel, CEO of biotechnology

specialist, Bind-X, said: “The biggest

trend within dust control is the transformation

towards products that have no

negative impact on the environment,

the operational safety and the health of

workers and communities nearby.”

For solution providers, the biggest challenge was to provide alternative products that offer better performance than conventional products with the same application convenience and cost structure. Once applied, a solution that effectively binds the wearing course must offer durability and longevity of dust suppression to reduce the frequency of reapplication on haul roads. Overall, this means fewer water truck trips which immediately improves the environmental performance of mining operations through a reduction of water used, and CO2 emissions.

General Manager of Bind-X, Alex McHaffie, explained: “The dust suppressant mode of action and it’s performance must be linked to the decarbonization strategy of the mine operations to minimize environmental impacts over the lifecycle of the mine.” Innovative alternatives to chemicals, mostly biological-based alternatives, can enhance the longevity and performance of treated infrastructure in certain instances, eliminating the need for water-only methods as well as reducing any non biodegradable raw materials used in chemicals for dust suppression. Biological products can sometimes be more flexible in formulation too compared to pure chemical approaches, e.g., they can have additional functionalities, such as binding of very small particles, integrated.

Spitznagel added: “Now is the perfect time for joint efforts from all stakeholders to transition the mining industry towards more efficient and environmentally friendly dust control practices that include, at their core, communities and the CO2 balance of the operation.”

Protecting Engines From

Dusting

Fugitive dust can also impact the operating

life of machines on site. Engines

require a clean source of air for combustion

and reliable operation. The failure of

air induction systems through damage to

ducting, broken hoses, loose clamps, failure

of air filtration media or human error

during maintenance, can allow unfiltered

air to enter the combustion chambers.

Jason Green, President and Chief Technology Officer at DustGuard Corp, explained: “Engine dust ingress, or ‘dusting,’ is a recurring issue that impacts almost every hard-rock mining operation. The only exceptions would be those in areas that receive a very high level of precipitation or in extremely cold climates. Even there, once the rain stops or the ground thaws, then dust levels will increase.”

The impacts of dusting depend upon the severity of the leak and ambient conditions. For example, small leaks that allow dust to accumulate incrementally over time can gradually reduce engine performance and accelerate wear, triggering early overhauls. Larger leaks can lead to rapid engine damage or catastrophic failure in a matter of hours, resulting in significant downtime and loss of production.

Visual engine inspections can be effective for identifying larger air induction leaks like damaged intake hoses, but smaller cracks or pinholes in ductwork are difficult to detect. Silica accumulates in engine lubricating oil over time so, today, dusting is primarily identified through oil analysis performed at regular service intervals. But very few mines have laboratories on site, and by the time samples have been collected, analyzed and technicians alerted to the presence of silica, damage has usually occurred. Mines need a system that alert them immediately to this problem.

In 2021, DustGuard Corp launched its eponymous solution, DustGuard. This interfaces with engine air induction systems and uses smart, ruggedized optical sensors and advanced algorithms delivered via the cloud to continuously monitor air quality in real time. Operators and maintenance supervisors are alerted immediately through on-machine and remote alarms if dust particles in the critical size range and above a specified level are detected. This provides the opportunity to shut down the machine or bring it into the maintenance facility for inspection and repair.

The system is suitable for diesel, dual- fuel and spark-ignited engines (lowhigh speed) rated at 500-2,000 hp (373- 1,491 kW) or above. Up to four discrete air sample inputs allows for engines with multiple turbochargers or intake ducts. DustGuard’s first commercial roll out came at the beginning of 2022, and Green told E&MJ the company has seen a strong response from the market. “Our first customer — a coal mine in Wyoming, US — installed the system on one haul truck and was so impressed that they’ve purchased five more,” he said. “We’re seeing very strong interest from almost every mining company that we’ve talked to. Their universal response is that they have this problem, and they’re interested in a technology to solve it.”

Tackling Dust at the Source

Effective dust control strategies address,

not just fugitive dust, but also the source

of dust through equipment and process

adjustments.

Dirk Clark, Sales Manager at polyurethane

specialist, Reca Plastics, explained:

“With the right dust control techniques

at the source, mine operators

can save a lot of money and minimize

reputational risks. Year-on-year we are

having more intense discussions with our

clients to solve this problem. Companies

are looking for clean and environmentally

friendly solutions.

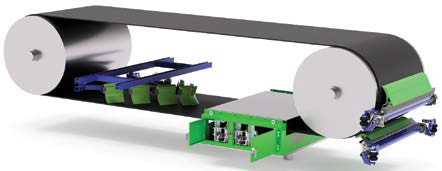

“Emission control systems on conveyor belts, such as scrapers, can effectively provide this. Scrapers remove material carryback from conveyor belts which is a major source of fugitive dust emissions. They also eliminate the need for cleaning under conveyor modules. In operations across the globe, personnel are not paying enough attention to belt scraping and this is causing secondary environmental and health problems as well as high operational costs. Many companies don’t realize that, with the right technologies, their operations can be nearly dust free today if they want.”

Reca offers a full range of conveyor belt cleaning products, from easy-to-change primary blades to sophisticated cleaning machines. Together with partners, the company is currently working on an innovative conveyor belt scraper which will soon be marketed as the BeltWitch Waterblade. “For nearly a decade, we have been working closely with a leading European mine operator to develop our low-wear, long lasting scrapers,” Clark said. “Our newest product is the 100% BeltWitch Waterblade scraper which fully eliminates any dust emissions on the return strand of conveyor belts. Also, when water is a sparse resource, the water can be recycled and reused many times to keep total consumption low.”

A Multi-pronged Approach

These solutions are just a snapshot of

those available on the market today to supress

fugitive dust, protect machines from

its effects, and minimize generation at the

source. The options are many and modern

dust control programs should be tailored to

include elements that effectively address

each operation’s unique challenges, while

protecting people, the planet and profits.