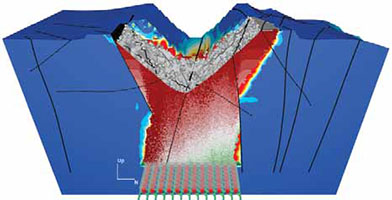

A screenshot from Itasca’s FLAC3D 7.00 modelling package. (Image: Itasca International)

Rewriting the Rules of Caving

Engineers are pushing the boundaries of cave design as mines head deeper

By Carly Leonida, European Editor

A key challenge with bulk mining methods such as block, panel or sub-level caving is that the designs are locked in from the development phase. There is little room for flexibility, and so learnings from early mining are hard to implement as the mine matures. “Living and managing any mistakes is part of caving,” Dr. Rob Bewick, Director of Technical Excellence & Innovation in Mining at WSP Golder explained to E&MJ. “A reliable methodology for cave design is needed, but this isn’t always straight forward. With the trend of mines going deeper, conventional design approaches that were learned from shallow caving operations of the past are not always relevant.”

One example of this is cave lift heights (the vertical column of ore that is to be mined between caving levels or the main extraction level and the ground surface); with increasing lift heights, new cave mines are finding that draw point interaction — an important design principle for caves of the past with smaller lift heights, say less than 225 m — is no longer relevant. “This provides the opportunity to modify traditional cave extraction and undercut layouts such that wider panel drives and draw point drives can be used,” said Bewick. “This creates larger, more robust and resilient extraction level pillars which make the extraction level potentially more stable (increasing production reliability) and also allows for larger tunnel sizes and mining equipment, increasing production.”

Larger tunnels can also better accommodate automation, further increasing opportunities for improved production reliability and safety. “There are simply not enough people to support the mines of today, nor the mines of the future,” Bewick said. “This makes automation very important. We need tools that allow us to do more with less.”

Shortage of talent is not only impacting cave operations from an operational perspective but a geotechnical one too. Bewick explained that true deep mining experience is currently limited to a small group of practitioners, and very few universities and colleges teach aspects of deep high-stress mining, whether related to how a high-stress mining environment impacts mine design changes or rock engineering design.

In mining generally, but especially in operations that use bulk extraction methods such as block and panel caving, reliable production is the name of the game. As mines head deeper, seismicity has the highest potential to impact the forecast of caving operations. A seismic event can damage tunnels over a vast area rapidly and with minimal warning. This is a significant risk to safety and can result in huge rehabilitation costs as well as production down time which impacts the net present value (NPV) of the asset.

Adapting cave designs so that automation is more easily implemented (reducing personnel exposure) and to increase stability (larger pillars and more stress efficient layouts) is critical to the reliability of future operations. However, this requires an intimate understanding of how the rock mass will react under different conditions — something that is usually gained through years of hands-on experience under expert supervision, the pool of which is beginning to dwindle. The same goes for ground control. Ground support systems are a signifi- cant cost driver in caving, accounting for ~60% of the cost per meter in some cases. Designing systems in a way that controls bulking, limits damage of production areas and maintains an acceptable factor of safety, while remaining cost efficient at depth requires significant expertise. There is a real danger that key learnings will be lost if recruitment and knowledge transfer across the industry are not improved.

Education, both at college level and beyond, will play an important role in propagating learnings from deep caves and in attracting new talent. Efforts can already be seen in the programs of key conferences, for instance, MassMin (last held in 2020) and Caving 2022, which is staged by the Australian Centre for Geomechanics. The fifth iteration of the latter event was held in Australia in August 2022 with presentations highlighting lessons from a number of current and future operations — open access to the papers is available on the event website.

Learning and Advancing

Together

Given the challenges outlined above, data

gained through monitoring and characterization

of the rock mass is playing an

increasingly important role in cave design

and operation.

“Underground monitoring coupled

with detailed ground models (rock mass

characterization) provide a solid base

line for forecasting,” said Bewick. “Some

things that have previously been hard to

monitor include the excavations themselves,

which are often a more expensive

asset than pieces of equipment, the cave

back, cave flow and seismicity. Today,

there is so much rock engineering data

in some mines that using the data to take

appropriate action can be a challenge.

Data management and usage are areas

that require critical improvements.”

Understanding ‘cave flow’ i.e., how material moves during excavation and how caves grow is an emerging field but an important one, not only from a production perspective but also in safety, capital allocation and maximizing NPV (missed recovery of the reserve and dilution have the ability to destroy value). “Cave flow is a major source of value and knowing what to do to maximize the value of the reserve is a massive opportunity,” added Bewick. Given the scarcity of expertise in deep caving today and tomorrow, close collaboration is essential to the success of operators who are new to these mining methods, and also in advancing the art of caving with teams who are more experienced.

WSP Golder has been assisting a major copper/gold mine with underground rock engineering and design since 2014. This includes de-risking the operations through critical infrastructure reviews of the most important assets, helping to model the impacts of ground support and design, and assisting with the company’s understanding of seismicity and rock bursting. “For another client, we have completed a full front-end loading 2 study (FEL2) and are now completing their FEL3 study,” Bewick told E&MJ. “This mine is shaping up to be a deep sub-level cave and we are incorporating our experience from deep, high-stress mines and deep caves into the design. The project is for a client new to deep mining, so we are taking them on a journey to adopt learnings, since the design principles are not like the conventional caving design principles.”

WSP Golder is currently involved with two research consortiums that are working to address shared challenges in caving. The International Caving Research Network (ICaRN), run by the University of British Columbia, is where WSP Golder has funded some collaborative research around numerical stress model benchmarking. As part of the Cave Mining 2040 consortium set up by Mining3, WSP Golder is providing two main contributions: Bewick’s own research centers on the strength and deformation of brittle rock masses and their applications in cave mining, while his colleague, Dr. Steve Rogers, focused on developing guidance for discrete fracture network modeling in caving.

“We also advance the state of practice internally at WSP Golder,” explained Bewick. “When we identify a challenge, we push the envelope to develop new approaches. An example would be our work around characterizing copper-porphyry rock masses. These are extremely hard to characterize, but we have progressively improved data collection and processing methods to better forecast excavation stability, ground support needs, rock bursting, and cave performance, among other aspects.”

Digitally Enabled

Developments

Itasca has over 34 years of cave engineering

experience applied at over 30 block,

panel, and sub-level caving operations

and projects worldwide. The company

is another keen participant in caving research

involved in the International Caving

Study, Mass Mining Technology, and

Caving 2040 projects, and its consultants

delivered a number of papers at Caving

2022. These detailed research into areas

including ground surface subsidence as a

result of caving, underground infrastructure

damage induced by cave mining sequences,

and the estimation of dilution

content in caving.

Like WSP Golder, Itasca sees these

types of research programs and events as

an important opportunity to share information

and ideas to everyone’s benefit.

“We believe that the greatest opportunities

for improvements in cave

mining are related to deeper mining,

even better monitoring and more data,

hydrogeological modeling and research

collaborations,” David DeGagné, Senior

Engineer at Itasca’s office in Minneapolis,

US, told E&MJ.

His colleague, Geomechanics Engineer, Christian Cancino, added: “As cave mining becomes deeper there are two critical issues: the trend towards larger lifts and the transition into primary rock. Historically, cave mines utilized multiple lifts, but the current trend as mines go deeper is to have a single, large caving column from the bottom of the mine footprint. This presents challenges in terms of stresses, overall stability, and associated seismicity. Also, as cave mining extends beyond depths of 1 km (depending on the site), the nature of the rock mass transitions from a jointed rock mass (where the industry’s experience for cave mining and slope stability resides) into primary rock.

“Primary rock is massive to sparsely jointed and heavily veined. All our historical experience and empirical tools, like the Geological Strength Index (GSI), that have been used for decades to estimate rock mass strength are not always directly applicable for this deeper rock — sometimes established rock mass classification systems are no longer valid. Improved rock mass characterization and strength estimation is needed, and we need to improve our understanding of spalling theory, veined rock, and vein intensity, for example. These are not easy challenges to solve.”

The team believes that another opportunity for improvement along the lines of rock mass strength estimation is related to the effect of rock mass scale strength, where the same material strength is not appropriate for both the tunnels and caverns near field scale and the cave mass and subsidence far field scale. Numerical models will either need to couple different scale models (e.g., solve for stresses in the far field and apply this result to boundaries of near field infrastructure models) or investigate multiscale modeling.

“With improved equipment and processes, cave mines are now able to better monitor what is happening on surface, underground, and inside the cave,” said Miguel Fuenzalida, Senior Geomechanics Engineer at the Itasca office in Minneapolis. “Today, the critical questions are: how to interpret all this data? What is the procedure? What is the standard, and where should operators install monitoring hardware, so they don’t lose information or waste resources, especially as the cave columns get larger?”

Such data collection and monitoring will remain critically important for driving progress in cave rock mechanics. This data, combined with continual improvements in software and hardware speed and capabilities (e.g., cloud computing), will only help to improve numerical modeling reliability going forward. To this end, model validation will be critical. Current numerical models are often well-calibrated, but validation (ensuring agreement with all aspects of reality) could be improved.

Advancing Cave Simulation

Safety and economics are the two main

factors driving innovation in cave simulation

today. Operations need a good understanding

of the caveability of the orebody,

how the broken rock is distributed,

and how it moves within the cave. This

provides foresight into the risk of air gaps

and subsequent air blasts, as well as mud

rushes at draw points due to fines migration

with the presence of water.

“In terms of economics, mining companies are demanding better forecasting of dilution entry, recovery, and fragmentation to better estimate draw point productivity,” Cancino told E&MJ. “The ability to estimate fragmentation and the need for secondary blasting or orebody pre-conditioning provides guidance to resource allocation during initial development and over the life of mine (LOM). Prediction of where and when any surface subsidence may develop is also essential.” Previously, mining operations had to rely on empirical charts, prior successes and failures and, to some degree, monitoring outside of the cave mass. But over the past decade, engineers have gained access to more and better in-situ monitoring data and faster, more powerful computing software and hardware.

“Historically, site data was limited to what could be observed at the draw points, within underground openings, and from surface, which made it challenging to understand the mechanisms involved in caving and predicting mining results,” explained Fuenzalida. “Today, in addition to these observations, cave mines routinely add time domain reflectometry (TDR) or smart cables, beacons or smart markers, and improved seismic monitoring, and more accurate measurements of subsidence and underground closures.”

Dr. Patricio Gómez, General Manager and Applied Geotechnical Engineer at Itasca’s Chilean office, added: “Monitoring technology has evolved in recent years to the point where it’s possible to monitor in real-time the evolution of the cavity and follow the movement of broken rock in mineral columns. This new data has led to better understanding of caving and material flow mechanisms that allow the development of new numerical modeling tools, and provide a means of calibrating and validating numerical models to predict future mining responses more reliably.”

A Holistic View of

the Rock Mass

Over the past decade, Itasca’s engineers

have gained a greater understanding of

the behavior of rock masses undergoing

caving through practical work for

clients and fundamental research. This

has culminated in the development

of a new constitutive model called the

Itasca Constitutive Model for Advanced

Strain Softening (IMASS) for use in the

FLAC3D and 3DEC software packages as

well as a new software for material flow

simulation called MassFlow. MassFlow

is currently in beta testing and will be

released in late 2022.

IMASS, the progeny of Itasca’s Cave- Hoek constitutive model, simulates the progressive failure and disintegration of the rock mass from intact, jointed and/ or veined rock to a disaggregated, bulked cave mass in response to excavation-induced stress changes. Cancino explained: “IMASS properties are strain-dependent, based on two-residual strength criteria, and change to reflect the rock mass strength due to the impacts of fracturing, dilation, and bulking as it undergoes plastic deformation. This allows us to track the full spectrum of the post peak behavior from a material that has just failed to fragmented rock within the cave, where porosities can be quite high.”

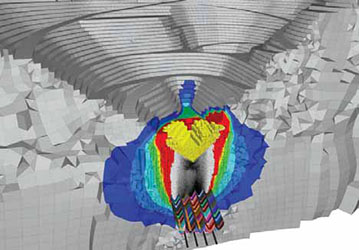

Key to improved cave modeling is the ability to accurately capture the impact of draw and material flow based on the production schedule, on cave propagation and subsidence. MassFlow uses a deterministic, physics-based algorithm for simulating material flow (collapse, bulking, and movement of caved rock). “While both geomechanical and material flow modeling provide valuable insights inside the cave mass, it’s when the FLAC3D or 3DEC models (using IMASS) are coupled together with MassFlow that we find the greatest value,” Fuenzalida told E&MJ. “With coupling, we use Mass- Flow to calculate the flow mass balance as material is extracted from the draw points, based on the production schedule, and model the resulting induced mine stresses using FLAC3D or 3DEC (with IMASS).”

Today, much of the focus in cave mine engineering is on ‘the big five’ geomechanics concerns: caveability, ground subsidence, infrastructure stability, fragmentation and material flow. However, it’s also important to incorporate hydrogeological modeling to cover the full gambit of cave design and operations. Over the past decade there have been continuous improvements in the prediction of ground displacement and the properties of the cave mass from better geomechanical modeling.

These are some of the most important inputs to Itasca’s MINEDW hydrogeological model to accurately predict water inflow into underground mine workings as the displaced rock mass will have higher hydraulic conductivity and provide the pathways for groundwater, precipitation, and surface water runoff to the underground workings. This provides foresight into the need for infrastructure rehabilitation, and the risk of air gaps, air blasts and mud rushes at draw points which are some of the greatest risks in cave mining today. Houmao Liu, General Manager and Principal Hydrogeologist with the Itasca office in Denver, explained: “Using MINEDW, we can accurately predict the water content distribution within mobilized materials, which is a key input for the overall assessment of mud rush risk. MINEDW also enables accurate prediction of water inflow to the mine workings, which is important in underground water management.”

Bonded block modeling (BBM) in 3DEC, with several recent improvements, is another important tool for simulating cave growth and fragmentation. The BBM modeling approach represents rock mass damage through the interaction and breakage between joined polyhedral blocks representing intact rock. Breakage of sub-contacts between blocks, based on stress concentrations and rock mass strength mimics the initiation of cracks that can coalesce and/or propagate to fracture the rock mass. This results in an emergent damage pattern with associated bulking.

Itasca’s 3DEC BBM inherently represents a zero initial porosity condition, as well as interlocked irregular blockshapes, that provides resistance to block rotation after contact breakage. This better represents the high uniaxial compressive strength to tensile strength ratios and friction angles typically exhibited by hard rock. 3DEC also allows for the addition of joints, including hydraulic fracturing used in pre-conditioning, to be explicitly represented by overprinting them as cuts on the intersecting blocks. “With IMASS and MassFlow, over the LOM, we have a much better understanding of the stresses impacting mine infrastructure, caveability of the orebody, how the broken rock is distributed, and how it moves within caves,” said Fuenzalida.