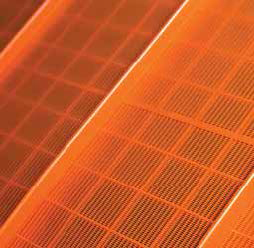

General Kinematics screens are famous for their Two-Mass technology. (Photo: General Kinematics)

Screens Offer New Era in

Process Efficiency

We present the latest developments in vibratory screening technology from eight

leading vendors

By Jesse Morton, Technical Writer

Digital solutions have also proven invaluable over the past 12 months, allowing operators to monitor and control screens remotely, predict potential issues and schedule maintenance activities more efficiently. As mines explore this new potential, vendors have been working to boost their manufacturing and service capabilities, add new solutions and better serve their client bases. We spoke to eight equipment providers about the trends they are seeing across the industry and how they are responding.

Derrick Boosts Mine’s

Green Credentials

Derrick Corp. is known for its decades of

development in high open-area polyurethane

screen media.

“When this is coupled with machines

using high-frequency and low-amplitude

vibration, the results are industry leading

conveyance and flux rates,” David Perkins,

director of technical sales for the

Mining and Industrial Division of Derrick

Corp., said. “Derrick equipment is capable

of processing more tons of material

per area than any other manufacturer. Installation

costs are often lower for the client

due to a smaller plant footprint, lower

total weight and negligible dynamic loads

to the supporting structures.”

Derrick equipment can be found on six continents in almost every commodity, from alumina to zirconia. Top markets include iron ore, gold, lead/zinc and silica. Derrick screens are often used to replace hydrocyclones in grinding circuits where clients benefit from increased product recovery and higher capacities that are beneficial to the environmental, social and corporate governance (ESG) impacts of a mining and processing operation. “We are seeing trends toward more environmentally- friendly processing. Clients are looking for ways to be more sustainable through process equipment that offers increases in capacity and recovery,” Perkins said. “In some cases, ESG is as much of a driver as cost to produce.” Derrick’s SuperStack technology features up to eight decks, each equipped with Derek’s patented polyurethane panels. The combination of these two technologies allows the machines to replace hydrocyclones in grinding circuits — essentially performing the role of classifiers — which they do much more efficiently and cost effectively. The result is that the operation can produce more product using the same amount of energy or less.

Screens separate material based on particle size, whereas hydrocyclones separate based on density. In some metal mines, there’s a big difference in specific gravity between the ore and gangue minerals but, in others, iron ore for example, both fine iron ore and coarse silica have similar densities so both will report to the overflow. It’s very difficult to separate the two using hydrocyclones.

“Screening can be a game changer for these operations,” Perkins said. “Screens offer higher recovery, send less material to tailings and increase profitability. Most of our projects have payback periods of two to three months.”

During the past 12 months, Derrick has been working to improve its customer relations and support with a wholly owned and operated international sales organization with local offices in South Africa, Canada, UAE, Indonesia and the USA. Staff are being added to support these offices and also at the company’s manufacturing facility in Buffalo, New York. “We recently completed delivery of 24 SuperStack screens to a Metalloinvest Management Co. LLC-Mikhailovsky GOK operation in Russia, as well as an iron ore mine in Brazil and a phosphate mine in South Africa,” Perkins added.

Vale’s Gelado project, part of the Carajás mining complex in the Pará state of Brazil, selected Derrick’s SuperStack technology to develop an innovative tailings handling method and create a high-value “green” product. The new process lowers emissions in mining and steelmaking, producing high-quality iron ore at a lower cost than other Carajás operations. Vale selected a single eight-deck SuperStack for Gelado’s fine screening requirements. This is fitted with 150 micron (µm) aperture high-open-area, wearresistant, non-blinding Polyweb screen panels to process more than 200 dry metric tons per hour (dmt/h) of iron ore.

“That is more than twice the capacity of the previous industry-leading technology in a similar footprint,” Perkins explained. “The patented Front-To-Back tensioning system reduces screen maintenance time by up to 75% compared to previous bestin- class screen tensioning systems.” The new process has allowed Gelado to turn the cost and risk associated with tailings management into a positive cash flow stream, and the project is expected to recover 10 million metric tons per year (mt/y) of high-grade ore from the Gelado tailings dam over a 10-year period.

FLSmidth: New Analyzer and

Wear Packages

FLSmidth supplies a range of premium

products, including vibrating screens,

wet gravity screens, rotary screens, roller

screens and screen media, to mines

across the globe in nearly every geography.

“There are some overlaps into construction

and aggregates, but our products

are designed specifically for the 24/7

nature of high-capacity mining operations

where reliability and availability are a top

priority,” said global product director, Eddie

McKerr.

FLSmidth recently launched the Screen Motion Analyzer (SMAv2). The lightweight, portable unit is temporarily affixed to vibrating screens using magnets and records the vibration of the screen in three directions (horizontal, vertical and lateral) simultaneously. The device then calculates and displays information on screen operating frequency, vibrating stroke and lateral displacement (Pk-Pk). The data is automatically transmitted via wireless Bluetooth to a user-friendly app (on any Android or iOS device), which displays the data in a way that is easy to interpret, with no specialist training required. The data and reports can be saved for records, further analysis and/or sent to an FLSmidth machine analyst for an expert opinion.

Vibration analysis provides detailed information about the performance of each machine and shines a spotlight on potential problems that could reduce their life. The SMAv2 provides an instant snapshot of machine’s performance, allowing mines to adopt a predictive maintenance approach, reduce their downtime and cut costs. “The SMA is ideal for on-the-run monitoring of screens between major shutdowns,” McKerr said. “We are also working on optimized wear packages with products, such as our FerroCer Impact Wear Panels and screen media with enhanced wear life, all of which can enhance the user experience and reduce equipment downtime.”

FLSmidth has also been working to improve its vibrating screen protection guards. The guard’s new homogeneous molded design eliminates fabricated joints to reduce stress points and increase their strength. McKerr explained: “We have developed a product using improved material, which makes them lighter weight. The smarter design makes removal and installation easier, and longer life is delivered due to the material chosen for manufacture and subsequent corrosion resistance.

“We see a focus on customers driving toward more value for money and reliability of equipment performance. This is why enhancing our wear package options is an important endeavor.” During 2019-2020, FLSmidth actively replaced a number of linear belt screens with its more reliable and effi- cient vibrating screens. “A case study is currently being developed with a gold mining customer and should be ready for release later this year,” McKerr added.

General Kinematics Takes

Two-Mass to MINExpo

General Kinematics is known as the leader

in Two-Mass vibratory technology for screens.

“It’s a game changer for the industry,”

Derek Kerkera, market director for mining

at General Kinematics, explained. “We

have been doing two-mass designs since

our company began in 1960.”

Two-Mass refers to a style of vibratory equipment where one mass (the exciter, i.e., the drive) is used to mobilize a second mass (the trough or body). The exciter mass is the total weight of the vibratory motor(s) plus the steel structure designed proportionally to the total trough weight in addition to the amount of the material load. The exciter mass is connected to the trough structure through a network of springs distributed evenly between the two. This creates a sub-resonant system that responds to changes in load without dampening performance and efficiency.

One of the biggest benefits of the Two- Mass design is it’s longevity. Machines generally last longer than their industry counterparts. “Typically, we see brute force machines failing structurally between six months and two years of operation, while our Two-Mass designs will operate for five to eight years before needing refreshing,” said Kerkera. During the past year, General Kinematics has focused on the Canadian, Mexican, South American and Australian markets with forays into South Africa too. The company made two acquisitions in early 2021: Cyrus and Foundry Equipment Co. were purchased to increase its capability with turnkey projects worldwide and also to increase its presence in Europe and South Africa.

“Many clients wish to increase their capacities at the moment in line with demand and commodity prices, so we’ve been testing more material in our lab,” Kerkera explained. “Most comminution circuits run well below their design tonnage due to brute force screens that are unable to operate reliably at circuit design tonnages and required efficiency. “It’s always better to handle any material loading with the least number of screens possible. This way operations do not need to split and recombine flows and less overall equipment is required.”

General Kinematics is currently finalizing an STM S3685 single-deck screen which is destined for Copper Mountain in British Columbia later this year. The unit will be delivered via a brief stopover at MINExpo where it will be the star of the General Kinematics booth. “It will be their second unit from us,” Kerkera said. “This model features a new patented spring design called the ‘Duro’ spring. Typically, a spring is bolted by attaching the pig tail of the spring to a plate putting the mounting hardware in tension. The Duro spring doesn’t have a pig tail, it has a swaged end to the spring which put the mounting in shear. This is a much better condition and removes the issues sometimes seen from erosion. It also allows a higher stroke level with less stress on the spring.”

Kwatani: Engineered for

Tonnage

Kwatani has 46 years of experience supplying

more than 16,000 customized vibrating

units into 47 countries worldwide.

It designs and manufactures a range of

linear-motion vibrating screens and feeders

which are driven by in-house manufactured

exciter gearboxes or unbalanced motors.

Kwatani announced on May 7, that it’s to be

acquired by Sandvik Rock Processing Solutions.

The transaction is expected to close

in Q4 2021 subject to regulatory approvals.

“The majority of our screens are between

8 and 14 ft wide and available in

either single, double or triple-deck configurations,”

said Jan Schoepflin, manager

for general sales and Service.

Kwatani offers a complete screening application portfolio from ROM equipment such as grizzly and scalping screens (the largest processes 7,000 mt/h of iron ore), to high-capacity multi-slope screens, desliming, drain and rinse, dewatering, and sizing screens up to 4.8 meters wide, including a range of brute force feeders. “Aside from customizing the deck layout and footprint for our machines, we customize each screen’s parameters including the drive angle, decline, stroke and acceleration to achieve the optimal design,” explained Schoepflin. For example, in certain applications Kwatani’s vibrating screens incorporate a higher stroke and G-force which can lead to increased throughput and efficiency.”

“Traditionally, we’ve had a strong presence in southern Africa, but we are developing into Europe, North and Latin America and Russia,” she explained. Kwatani is currently manufacturing screens for gold mines in Quebec and Ontario; a coal mine in Siberia; chrome and diamond mines in Russia; diamond mines in the Republic of Congo, Angola, Lesotho Botswana and South Africa; a mineral sands operation in Madagascar; and copper mines in Zambia and the DRC among others. “We recently received an order for a diamond project in Australia which will help us become more known in this market,” Schoepflin added.

Schoepflin noted that the industry is currently under huge cost pressure and mining customers and project houses are reacting in two different ways. “On one hand, customers focus on reducing their capital expenditure, while on the other they demand reduced lifecycle costs which include a reduction in maintenance costs, avoiding unplanned stoppages, increasing production tonnages and efficiency,” he explained. “Kwatani offers a competitively priced product paired with an optimal lifecycle and service offering. We are able to offer competitive prices for our equipment due to optimized production processes, currency hedging and our location in South Africa. “For brownfield projects/competitor replacements, we have a dedicated team to take measurements on site and so far, Kwatani has always optimized the effi- ciency and performance of the screen on the same plant footprint.”

Multotec’s Home and Away

Focus

Multotec manufactures a range of mineral

processing screens and media for mining

operations across the globe. Roy Roche,

vice president of screening Media at Multotec,

spoke about the company’s current

focus areas.

“What sets Multotec apart is that we

use a wide range of construction materials

in our screen media,” he explained. “We

control the manufacturing process ourselves

and utilize an iterative improvement

process to extract longer term benefits for

our customers. We combine this with deck

map technology, wear life indicators and

monitoring capabilities that further enhance

their performance capability.”

The African markets remain Multotec’s top priority going forward, although the company has also seen success in Australia, Chile and Central America. “Significant expansion is currently under way in China, with the recent commissioning of a new 3,000-m2 manufacturing facility in Beichen,” Roche said. “We are also expanding in Chile with the addition of another factory to significantly increase our manufacturing capability in South America. And we are expanding both our service and manufacturing capability at our Belo Horizonte facility in Brazil.

“Geographically, we are focusing on Southern hemisphere mining jurisdictions in conjunction with other markets like China, Russia and the CIS, and Canada. Bulk commodities like coal and iron ore make up a big chunk of our business along with base metals (copper, chrome, manganese, cobalt, nickel, etc.), precious metals and diamonds.” The Multotec R&D department is constantly busy developing and testing new screening products. Francois Fouche, senior screening specialist at Multotec, expanded on some recent developments.

“The new range of MBV screen media has been developed to improve the screening efficiency of fine, damp material without the addition of water,” he said. “The panels comprise a thin flexible membrane that allows screening at high G-forces. The product has been found to be particularly effective with sticky ores with a high clay content.”

Multotec’s South African engineers, in conjunction with Multotec in Australia, have also developed a range of hard-wearing impact panels for the iron-ore industry. The panels use a combination of alumina ceramic or Hardox steel inserts in combination with rubber to counter wear at the feed end of vibrating screens. Customers have reported the wear life of these Ceradox and Hardox panels to be three to five times that of conventional rubber impact panels.

“We also developed a range of fire-retardant rubber screen panels that comply to the stringent safety standards set by some of the major iron-ore producers in Australia. These drastically reduce the fire risks associated with rubber products,” Fouche added. “Stainless steel wedge wire has long been the standard material for the manufacturing of interstage cylinders for carbon- in-pulp and carbon-in-leach sections in gold plants. Multotec has developed a new interstage cylindrical screen using a polyurethane screen surface. This is currently undergoing testing at a number of South African gold plants. Results to date indicate that the wear life will be superior to wedge wire and that the product could provide a viable alternative to conventional wedge wire cylinders.”

Multotec receives frequent inquiries to screen material at finer apertures. The bottom range for separation by screening has traditionally been in the region of 300 microns, but today, customers are asking for niche products that can screen at 100 microns. “We have developed screen media in both wedge wire and polyurethane that can screen at this size,” Fouche said. “This has called for investment in manufacturing and tooling in order to achieve this.” Roche added: “Another major trend we’re seeing now is remote monitoring of equipment in-situ, and the ability to predict failure patterns along with consistent product performance. Customers want products to meet predictable lifecycles so that they can improve and plan maintenance schedules. This is guiding our R&D endeavors where we are working with sensor systems to transmit relevant and coherent data related to specific product performance. This is aimed at eradicating catastrophic in-situ failures, unplanned maintenance and facilitating report backs on inefficient operating states. Artificial intelligence will play a significant role in these systems.”

Polydeck Pushes

Boundaries in Media Design

Polydeck develops screen media for the

most aggressive and difficult applications

in mines worldwide. The technology behind

these solutions has been continually

improved for more than 40 years.

Frank Harris, director of mining sales,

said, “We focus on reliability and process

improvement and we are the best at it.

Polydeck is fortunate to have the most talented

engineers in the mineral processing

field, and we are led by ownership that has

the vision and drive to be the best screening

resource in the mining industry.”

The company recently expanded its

manufacturing operations in Spartanburg,

South Carolina and, in April, was named

winner of the South Carolina Chamber of

Commerce 2020 Safety Award Winner for

Workplace Safety.

“Our team works closely with mining operations to ensure that they realize the benefits they expect,” Harris said. “Any product can be misapplied. Our mission is to ensure clients realize the value promised by helping them apply the right solution.” Polydeck recently helped Barrick’s Golden Sunlight operation in Montana to improve the throughput of its screens and reduce downtime. The mine was using heavy gauge wire cloth on its secondary scalping screen and experiencing buildup problems. The excessive travel rate and lack of bed depth were also causing issues. The threeto four-week average wear life was poor relative to other plants, and so the Polydeck team suggested switching the wire panels for its Rubberdex screen media.

Using 40 durometer rubber allowed the operation to run the screen backward, slowing the travel rate and allowing more efficient separation. It also helped solve blinding and plugging issues. Earlier this year, Polydeck released two new lines of ceramic and magnetic liners. The Magnetic Liners are designed with a combined holding force of up to 600 lb. Magnets are molded into the liner to maximize the surface holding force. The design also features molded 1-in. spaced cut lines to make in-field modifi- cations easy for any installation.

Constructed of high-quality Armadex synthetic rubber, the modular Ceramic Liners provide long wear-life with high abrasion resistance and reduced noise levels, for lower maintenance costs and improved safety. Polydeck can mold the liners with different durometers to match any application.

Like many other manufacturers, Polydeck has jumped headfirst into the world of online training and education over the past 12 months, providing specialized training courses to help customers overcome COVID-related travel restrictions. “These help them continue to improve screening processes at a time when we can’t be on site as frequently, or with as many people,” Trey Rollins, director of marketing and inside sales, explained. “Additionally, Polydeck has created informative webinars on topics most requested by customers as a way to stay in front of customers and potential customers. The increased willingness to utilize technology has also been a driving factor in the R&D space. We are fleshing out some ground-breaking concepts that will help solve huge problems for our customers. “We will be launching a new product category and providing a sneak peak of a new product line that will launch in early 2022 at MINExpo in September,” he added. “Both provide longer life, reduced wear and cost savings.”

TEMA ISENMANN: Right

Media for Each Application

TEMA ISENMANN manufactures a range of open-cast and injection molded polyurethane screen panels, as well as patented

magnetic liners and panels at its

base in Lexington, Kentucky. It primarily

supplies the North American mining and

aggregate markets including the USA,

Canada and Mexico using direct sales

personnel and a network of dealers.

“There are lots of options available in different durometers from 60 to 90 shore A. In addition, we manufacture a range of dual durometer panels where we combine a soft 60 shore polyurethane top layer with a harder base in different colors. This not only improves certain screening applications, but the different colors work as a wear indicator — when you wear through the top blue layer and expose the bottom yellow layer, it’s time to replace the panels. This versatile range of materials and panel sizes allows us to manufacture panels to suit most applications.”

TEMA ISENMANN’s range of injection molded modular panels are available in 1- x 1-ft sizes and are generally used for fine screening applications down to 300 microns. “Since we are part of an international group of companies involved in the mining industry [that includes Steinhaus GmbH; Isenmann Siebe GmbH; Tema Group and Multotec Group], we also have access to numerous other screen media and materials,” added Yell. “These include compression molded and injection molded rubber panels, and hybrid Poly-Wedge panels that have a combination of stainless- steel wedge wire mats fastened to a polyurethane frame. This means they are consistent with the modular concept of 1- x 1-ft, 1- x 2-ft and 2- x 2-ft panel sizes.”

TEMA ISENMANN also offers a range of TeePee high open-area, 3D panels that typically have double the open area of conventional flat panels, which results in double the drain rates. These can be used to increase the dewatering capacity of existing dewatering screens or allow the client to install smaller dewatering screens. “We regularly assist in checking screening sizing too, especially when clients want to convert from say woven wire to polyurethane to ensure they still have sufficient screening capacity available,” added Yell. “We make use of programs such as Agg- Flow to check mass balances, screening area and screening efficiencies.”

The company recently converted a number of mill discharge screens from conventional injection molded panels to open-cast polyurethane, and has more than doubled the life in many of these applications. Yell explained: “With regard to new products, we are continuously growing and improving our range of apertures in both open-cast and injection molded panels. Our range of WS2.10 patented magnetic panels assist clients with reduced maintenance down time, especially on second and third decks where panels are notoriously difficult to replace due to space constraints. They are quick to remove and replace safely with minimal tooling.”

Yell said the WS2.10 magnetic liners are proving exceptional in reducing downtime and, as there is no bolting required, there is no need for cutting and grinding equipment, which improves the safety of installation and removal. Another benefit is that plants can now standardize liners as they no longer need to keep left and right-hand versions, reducing inventory and costs.

The Saddle Top Rail System that has proven itself over the last 15 years in Africa and Australia, will be launched at MINExpo for the North American market and is fully compatible with existing runner systems. “It has proven to be far superior to most runner systems in the market not only because it extends runner life and is quick and easy to replace, but it supports the internal frame of the screen panels properly,” said Yell. “The polyurethane- polyurethane interface extends the panel life as well.”

TEMA ISENMANN’s WS85 panels, rubber screen panels, Poly-Wedge screen panels and WS2.10 magnetic liners and screen panels will also be on show at MINExpo. “Our new magnetic-backed stroke gauges will be available free of charge to delegates,” added Yell. “These are really useful devices for checking whether a vibrating screen is operating to manufacturer specifi- cations. There are a couple of other things we have up our sleeve too, but we don’t want to give the game away at this time.