Gold producer Nordgold recently increases the processing capacity of its Taborny

Gold producer Nordgold recently increases the processing capacity of its Taborny

mine in Russia from 5 million

to 7.5 million mt/y. Included in the expansion project

is a new pumping station at the mine’s heap leaching site

comprising four Sulzer

pumps, each with a capacity of 400 m3/h.

The number of pump types used at any

large-scale metal mining operation might

only be surpassed by the range of sizes,

body materials, power demands and maintenance

requirements associated with

them. Pumping tasks can differ greatly —

pit dewatering vs. mill discharge, slurry

vs. sludge, for example — and like the human

workforce that installs, inspects and

services them, some pumps are generalists

capable of handling a variety of jobs,

while others are specialists, designed to

handle dedicated pumping tasks.

They’re are among the oldest and most

tradition-bound equipment types used in

mining. As Harvinder Bhabra, head of the

fertilizers, metals, mining and chemical

process business segment at Swiss pump

builder Sulzer, pointed out in a white paper

last year, pumps have been used to

transfer fluids for centuries, progressing

from early Egyptian shadoofs — basically

a pole and a bucket — to the Greek

Archimedean screw and on to the highly

engineered designs available now.

They’re also a major part of the picture

in any future vision of Industry 4.0.

Bhabra noted that over time, as industry

processes became increasingly sophisticated,

specifications for various pump

types demanded innovative manufacturing

techniques to keep pace. Some of

these include hydraulic profiling, CAD/

CAM, computational fluid dynamics, fi-

nite element analysis and 3D printing.

Most recent developments link to the advent

of the Internet of Things (loT) and

the collection of pump operating data

and condition monitoring. Real-time visibility

of a pump’s performance provides

a reduced risk of unplanned downtime

caused by a failure. Mine-site pumps

also may be required to operate long after

mining activity ceases, for care and maintenance

purposes; reliability and remote

monitoring capabilities are critical factors

in those applications.

Next-generation models will likely not

just transfer media more efficiently but

will also be capable of sending performance

and machine health data at unprecedented

levels to a variety of digital

platforms and devices, as mining companies

continue to shift from capex to opexbased

models that demand constant and

comprehensive data flows for maximum

effectiveness. Increasingly, companies

are regarding pumps and the piping, valving

and control networks they’re part of as

an integrated fluids management system

that can be used innovatively to help resolve

broad industry issues of water usage

and energy consumption, along with

specific ongoing concerns about life cycle

costs, leakage and repair frequencies.

Design innovations that support this

approach are proliferating rapidly, encompassing

features ranging from easier access

for inspection and adjustments to quicker

changeout of wear-prone components.

Integrate for Efficiency

Mine and plant pumping requirements

can span a range of demands that vary

from simple and straightforward to multidimensional,

and obvious system choices

aren’t always the complete answer to a

pumping problem: For example, the favorable

economics offered by a properly

sized, efficiently powered and well maintained

pump can be degraded by a piping

setup that causes severe water hammer

incidents resulting in leakage or pump

damage; or a crucial heavy-duty valve may

be so large that it requires extra vertical

clearance to install and operate — and a

crew of workers to safely maintain it; or

perhaps a failing critical pipe section that

was assumed to be protected against corrosion by its fusion bonded epoxy (FBE)

lining should have been roto-lined instead

for better performance.

These are all reasons why an integrated

approach to pump-system design

usually pays off. (As an example, see the

accompanying sidebar describing how

one pump supplier’s methodology solved

multiple system demands at a Mexican

gold mine.) All major pump manufacturers

offer various levels of needs analysis,

design consultation and on-site support

both before and after system startup.

And, as we’ll see further along, third-party

participants such as electrical and

engineering contractors, pump component

suppliers and others can provide

significant value to customers through

advice and services related to pumping

facility location and layout, monitoring

and maintenance.

Recent pump models coming through

the product pipeline offer end users a

constantly expanding range of options

for pump-system flexibility. Tsurumi, for

example, has been particularly active

during the past year, adding to its LH

series heavy-duty submersible pumps for

mining applications and introducing the

GPN 837 heavy sand pump.

The new LH-D-series features two-pole,

110/185 kW motors and a double-suction

impeller to deliver reliable performance in

high-volume, high-head applications. The

company said the pumps, with a maximum

capacity of 14 m3/min and a maximum

head of 92 m, meet the needs of

open-pit and underground mining, heap

leaching and large-scale tunnelling work.

According to Tsurumi, an important

feature of the new LH-D series is the

ability to draw large volumes of water

from both the upper and lower sides of

the double suction impeller, thus reducing

thrust load, extending bearing service

life and increasing the stability of

pumping operations. The pumps have a

flow-through design that actively cools

the motor during extended operation at

low water levels and a useful inspection

window at the bottom of the stuffing box.

The top-of-the-line GPN 837 heavy

sand pump is rated at almost 2,400 gallons

per minute (gpm) and is designed for use whenever large amounts of solid

matter are involved, Tsurumi said, noting

that the unit can pass up to 30-mm

rocks. The 1,800-lb (815-kg), 39-in.-tall

(1-m) pump is powered by a 50-hp (37-

kW) motor and features an oil filter that

uses centrifugal force to lubricate in any

position. The GPN 837 pumps vertically

up to 78 ft (24 m) and when submerged

is pressure-resistant down to 30 m.

Tsurumi recently began to promote its

Tandem Kit, a pumping innovation developed

for high-head applications where

the need for strong output — and thus,

larger pumps — collides with a lack of

installation space, a situation not uncommon

in underground mining.

As a solution, Tsurumi developed the

Tandem Kit, which is attached to the casing

of the LH and LH-W series pumps and

enables two pumps of the same model to

be easily connected in series, providing

twice the total head of a single pump at a

fixed flow rate. The operating principle of

this method is the same as that of a multistage

pump, according to the company,

which has six 4- to 40-hp (3- to 30-kW)

pump models that are compatible with

the kit, with most featuring a dual impeller

design. The standard kit, which can be

easily attached to the pumps at the work

site, provides a maximum 833-ft (254-

m) head, and a 400-m head is achievable

with optional equipment.

Weir Minerals has launched several

new products, including the VL axial

pump, horizontal process pump and vertical

high-pressure molten salt pump, all

in the company’s Lewis line. In addition,

it introduced the mobile Multiflo LF pump

range, available in different configurations

to meet varied demands including applications

where liquids may contain high percentages

of solids or acidic conditions with

low pH values. Mounted on either a trailer

or a skid, the pumps are available with Tier

3 or 4 diesel power or an electric motor.

Weir said the pumps’ impeller design

and larger-diameter pump shaft enables

efficient handling of large solids while

reducing operational and maintenance

costs. This is achieved through an advanced,

high-efficiency pump-end that

requires less energy to process fluids.

Weir Minerals says its latest MultiFlo pump model features an

Weir Minerals says its latest MultiFlo pump model features an

enclosed impeller design and larger diameter

pump-shafts,

allowing the unit to efficiently handle large solids at lower

operating cost.

from 100 m3/h to 3,200 m3/h, and discharge

heads of 10 m to 210 m. The line’s

robust bearing frame and pump shafts

have been proven to result in fewer seal

failures and shaft breakages under extreme

conditions, according to the company.

Vertiflo announced the Series 1600

horizontal close-coupled, vortex end-suction

pump line, offering capacity up to

1,600 gpm, heads of up to 170 ft, and

capabilities for handling temperatures of

up to 250°F. The pumps, offered in cast

iron, stainless steel or alloy construction,

feature a convenient, cost-saving back

pull-out feature for easy inspection or

maintenance, and an impeller design that

facilitates better passage of solids, reduces

axial loading, and prevents dirt from

entering the sealing area.

Innovation Leads to

Optimization

Innovative applications of existing technologies

and improved material properties

are also contributing to pump performance

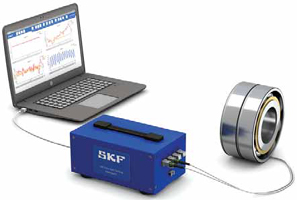

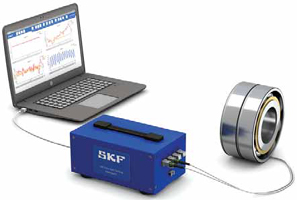

and reliability. Sulzer recently reported

that, by using bearing manufacturer SKF’s

fiber-optic sensing system to validate new

pump designs, it can confirm product performance

using actual measurement data

previously unavailable. Sulzer said it used

the SKF system to verify the design of a

new centrifugal process pump.

The sensing system measures loads directly

in the bearing, which gives a deeper

insight into a pump’s actual operating conditions.

“Design verification, using real load

data, is enabling Sulzer to further improve

its pump designs, and enable product design

verification with real-time data rather

than calculated scenarios. It improves physical

test confidence and reduces time to

market” said Daniel Perreng, sales and market

champion, fiber optic sensing at SKF.

The system uses load-sensing bearings

with fiber optic sensors, fitting the

most commonly used bearing sizes used

in heavy-duty process pumps. Only minor

modifications are needed to install the

sensors in the bearing housing, according

to SKF, which explained that it measures

bearing loads, and changes in loads and

directions, accurately and repeatably. The

system can also determine housing and

impeller qualities and alignment.

A major pump manufacturer used SKF’s new fiber-optic sensing system to

A major pump manufacturer used SKF’s new fiber-optic sensing system to

validate its design of a new centrifugal

process pump. The system can

measure bearing loads and also can determine housing and impeller

qualities and

alignment, according to the company.

It was tested and validated on a Sulzer

mechanical test rig. SKF said that while

Sulzer used the system in a research capacity,

an end user can also use it to collect

detailed data in the field. SKF will

offer global support for setting up the system

and training of Sulzer staff at their

R&D sites as well as provide data analysis.

Gorman-Rupp recently developed a

new integrally mounted diaphragm priming

assembly as an option on select 4-

through 12-in. (100–300 mm) Prime Aire

and Prime Aire Plus pump models. Offered

as an alternative to the venturi/compressor

priming system on Gorman-Rupp’s priming-

assisted pump models, the diaphragm

primer delivers up to 60 cfm (1,700 lpm), a vacuum to 30 ft (9.1 m) and is rated for

temperatures as low as 15°F (-9.4°C).

The company said the new primer assembly,

with fewer components, offers

reliability and increased efficiency, as

well as higher lifts. Reversed air flow and

thinner valves help any liquids entering

the primer to escape easily. The new primer’s

single-bearing housing has fewer leak

paths and alignment issues compared with

dual-bearing housing alternatives.

New synthetic-based products such as

SealRyt Corp.’s Style 2017 stuffing box

packing and South Africa-based Vesconite

Bearings’ Hitemp 160 can provide better

performance in tough mine pumping applications,

according to both suppliers.

Style 2017 packing consists of pre-twisted

high-carbon yarn with monolithic polyester

filament that is interbraided with an asymmetric

matrix. According to SealRyt, Style

2017 exhibits very high tensile strength,

is “shaft friendly” and resists picking and

fraying wear, along with offering significant

heat dissipation properties. Its pre-twisted

configuration allows all beneficial material

characteristics to be present throughout

the entire product matrix.

Earlier this year, Vesconite reported that

a pump containing three sleeve bearings

made from its new bearing material, Hitemp

160, which can operate at temperatures

up to 160°C (320°F) and is

resistant to abrasion, was tested and received

South African Bureau of Standards

(SABS) certification.

The pump tested, according to the

company, is part of a range of large vertical

spindle suction pumps that will be

primarily used in mining. “The pump

manufacturer tested and included our proprietary

Hitemp 160 material, which has

excellent abrasive properties, negligible

water swell and allows the pump to run

dry periodically,” said Phillip de Villiers,

Vesconite pump applications specialist.

“Having a material that could aid in the

pump’s need to run dry occasionally for

short periods of time was a priority, and

our material could serve that need in

this specific application,” noting that the

new material fills a gap in the market for

high-temperature bearings that are able to

operate in immersed conditions.

Ehouses Enter the Picture

Project owner reluctance to construct permanent

structures at remote mine-site

locations is converging with the industry’s

attraction to digital solutions and modular

design to drive increasing interest in

Ehouses and similar movable enclosures

for pump power, control and protection.

As E&MJ reported in the November 2020

issue, Weir now offers a skid-mounted

pumphouse that features towable relocation

capability, adjustable leveling, an internal

gantry crane, pump component lifting

jigs and multiple access points for ease of

maintenance. One of these mobile systems,

recently delivered to a client, incorporates

an integral gland water supply system and

a three-point pump base-mounting system,

which allows the base and skid to act independently,

minimizing the risk of pump and

motor shaft misalignment during operation

and the relocation process.

Ehouses offer an economical, easily relocatable and flexible solution for mines that need to

Ehouses offer an economical, easily relocatable and flexible solution for mines that need to

house and protect pump

controls and other low- to medium-voltage equipment in remote

areas. (Photo: Morrrison-Maierle)

Ehouses — transportable prefabricated

electrical equipment structures containing

medium- and low-voltage switchgear and

motor control electronics — are gaining

popularity, in part because the reduced size

of this gear due to digitalization allows more

of it to be packaged efficiently in smaller

spaces. E&MJ asked Brian C. Literski, electrical

engineer with engineering and professional

services group Morrison-Maierle, to

describe some of the advantages Ehouses

can provide in pumping applications.

Literski, who has designed a number of

Ehouses for Morrison-Maierle clients over

the past 8-10 years, said project scheduling

benefits are the primary driving factor

for Ehouse orders from mining clients.

“Mines identify a project, get it funded

through their process, and then hurry to

get the project installed within the fiscal

period. The Ehouse approach enables the

owner to procure long lead-time items —

medium-voltage VFDs, for example — and

have them shipped to the Ehouse manufacturer.

The Ehouse manufacturer concurrently

works on the building structure

and once they receive the equipment they

can install, test and wire most of the components

in a matter of two to three weeks.

“Another plus for Ehouses is that once

the design is bid and priced, we have seen

very few change orders on them. Pricing is

firm except for shipping rates, which are

usually determined in the last few weeks

before delivery,” Literski explained. Quality

control and labor costs also enter into

the equation: “Having qualified trades

people working [on an Ehouse] in a manufacturing

facility helps with quality control

of the installations, and labor costs

are lower” because project owners may

avoid having to pay on-site workers overtime

or per diem, he noted, particularly

when conditions at the installation site

can result in schedule disruptions. And,

he continued: “The systems contained in

the Ehouse are also more ‘plug and play.’

The entire unit arrives ready to be set in

place and have external wiring connected.

The internal wiring is already completed

with equipment mounted and tested.”

Ehouse sizes vary, Literski said, with

typical dimensions in the range of 12

ft wide x 40 ft long x 12 ft high or less,

which makes shipping logistics easier. He

also designed a unit that measured 14 ft 2

in. wide x 46 ft long x 13 ft high, weighing

about 90,000 lb with equipment installed.

“I’ve also seen two structures bolted together

to make a wider Ehouse with passthrough

doors to access each side. And

when the pumping station only uses low

voltage (480 volts or below), we can use

a Conex style — 8 ft wide, with varying

lengths — to house the equipment.”

These enclosures can easily meet the

industry’s need for expanded instrumentation,

data collection and security, said

Literski. “We’ve included control panels

and communications equipment in every

Ehouse we’ve designed. The data links we

provide to these units have enough bandwidth

for process control data delivery as

well as security cameras. And Ehouses are

not just limited to pumping stations; any remote

location that requires electrical power,

data acquisition, or a combination of both

are good candidates.”

Valves: Less is More

Valves may not be the largest cost-per-unit

item in a piping system, and their selection

may not be at the top of project engineering

focus, but the wrong choice — either

from cost considerations or misapplication

— can have a disproportionate effect on

process efficiency and facility safety. Lack

of corrosion resistance, inappropriate pressure

ratings and pressure loss throughout

the system, or unnecessary system weight

and stress are all problems that can contribute

to poor piping-system performance.

Weir Minerals, for example, unveiled

the Isogate WR knife-gate valve line,

which the company said is designed to

provide higher reliability at considerably

less weight than equivalent mining valves.

“We’ve optimized the Isogate WR knife

gate valve’s body design, by reinforcing the

areas subjected to the harshest wear and

pressure. At the same time, we’ve reduced

the weight elsewhere to produce a robust,

long-lasting mining valve that’s signifi-

cantly lighter than comparable products,”

said John Abbott, global product manager,

valves and tailings. “The weight reduction

can be especially significant in situations where a number of valves are used on a

specific installation, such as in a hydrocyclone

cluster, or where lightweight piping

systems are used.”

The gate has also been redesigned,

with stronger materials resulting in a

thinner gate that can still withstand the

pressure of mining slurries. This combines

with a unique gate guide that reduces

deflection by ensuring smooth gate

movement and less stress on the sleeve

elastomer during blade transition.

The Isogate WR knife gate valve features

the IsoGate WSL sleeve, which, according

to the company, uses proprietary

Linard HD 60 silica-reinforced natural

rubber to solve three common problems

with sleeved knife gate valves: leakage

during cycling, tearing and load distribution

ring (LDR) failure due to corrosion

and erosion. The Isogate WSL sleeve fully

encloses the LDR to prevent corrosion. By

allowing the rubber to move as the blade

cycles, the design reduces the chance of

tearing while reducing slurry discharge by

up to 75%. The sleeve, according to Weir,

also can also be used in existing Isogate

WS knife gate valves, improving wear life

and decreasing discharge on cycling.

“When designing the Isogate WR knife

gate valve, we focused on features that improve

the everyday experience of working

with our valves. This includes important

things like improved grease distribution

and improved body flushing when used on

high solids concentration applications. Indepth

finite element analysis (FEA) enables

us to ensure the product’s integrity, while

making it lightweight. There are also a lot of

smaller features to make life easier, such as

a larger grease reservoir, ISO mount standardization

and an external visual indicator

for the valve’s status,” Abbott said.

Last year, Flowrox introduced a major

design change for its larger (>DN 900)

slurry knife gate valves. The traditional

valve-actuator tower design, according

to Flowrox, usually works well with this

range of valve sizes, but also results in

extremely tall units. Flowrox’s new design

eliminates the cylinder tower and repositions

the actuator cylinders to the side,

significantly reducing valve height.

As an example, a DN 1200 valve with

the traditional tower design could be as

tall as 5.6 m (18 ft) in open position,

making the valve more difficult to handle,

less stable during assembly and harder to

access for maintenance. The new Flowrox

design for valves from DN 900 to DN

1500 has actuator cylinders on each side

of the valve. Compared to the conventional

design, a Flowrox DN 1200 knife gate

valve is only 3.6 m (12 ft) tall in a fully

open position. All maintenance access

points are located less than 2 m from the

ground, making them easily accessible.

Another change affects the valve body,

which in conventional designs comprises

two pieces that are bolted together, increasing

the possibility of leakage and requiring

tedious unbolting/bolting during maintenance.

The new Flowrox valve body is cast

in one piece, reducing the risk of leakage

and containing fewer parts, for savings in

spare part inventory and maintenance time.

Red Valve’s long-established and popular

Series DX slurry knife gate valve was

designed to be durable and user-friendly for

difficult slurry applications, according to the

company. The fully elastomer-lined DX prevents

slurry buildup or dewatering by eliminating

the seat cavity. Reinforced elastomer

sleeves seal against each other, providing a

100% full-port opening, minimizing turbulence

and wear when the valve is open. Seats

isolate and protect metal parts from contacting

process media. When closed, the sleeve

provides a drop-tight seal in both directions.

As featured in Womp 2021 Vol 04 - www.womp-int.com