The mining industry’s growing appetite for real-time data collection and analysis brings with it an equally robust

need for wider use of mobile devices and

The mining industry’s growing appetite for real-time data collection and analysis brings with it an equally robust

need for wider use of mobile devices and

broader sensor networks – all of which can also heighten an operation’s

vulnerability to cyberattacks when its data security and management practices can’t

meet the challenge.

“Data” might be the most imprecise word

in the language of business, both in terms

of meaning and value. For mineral producers,

a data item could be anything

from a momentary, routine signal from a

remote sensor, to a single cell in a vast

financial spreadsheet. As for value, how

is it measured? Is a gigabyte of drill hole

data worth more than a gigabyte sent

from a pipeline pressure sensor?

Sometimes the actual value of data can

only be determined when it’s misused or

missing. The cost of ignoring or misinterpreting

data from a haul truck temperature

sensor might be reflected in the price of an

engine overhaul, and the eventual financial

impact ensuing from theft of sensitive

spreadsheet information could provide a

quick indication of how much that data

was worth — both to the company that

owned it and the hacker who stole it.

One indication of how valuable a company’s

data can be was presented in a

recent article on the Forbes.com website

that pointed out that several large companies

in other industrial sectors (airlines,

retail, etc.), stressed by pandemic-related

economic factors, had certain data assets

appraised in order to qualify these assets

as collateral to secure large business loans.

The appraisal results, according to the article,

suggested the value of the data was

two to three times more than the actual

market value of the companies themselves.

Data management and data security can

be viewed as two sides of the same coin.

Data that isn’t well-managed probably isn’t

secure, and security measures won’t be

optimally effective without prior determination

of which types of business data are

most valuable and potentially vulnerable.

Management and security practices covering

the full range of mining activity from exploration

to port delivery need to be capable

of protecting vital information from misuse,

theft and corruption, because the threat

level to the mining industry is growing.

IBM’s Security business group released

a study of the financial impact of data

breaches on organizations that showed the

cost of these incidents has risen 12% over

the past five years to $3.92 million each

on average. The rising costs, according to

IBM, are representative of the multiyear

financial impact of breaches, increased

regulation and the complex process of resolving

criminal attacks. And, breach costs

aren’t short-lived: For the first time, the

report examined the long-term financial

impact, finding that the effects of a data

breach are felt for years. While an average

of 67% of data breach costs were realized

within the first year, 22% accrued in the

second year and another 11% accumulated

more than two years after a breach.

Given the scope of possible consequences

caused by cyber intrusion, the mining

industry has flashed mixed signals in response;

showing signs of casualness about

the matter in some cases, while in other instances,

it has moved forward positively to

meet the challenges. Two examples:

The Australian survey organization

State of Play, after interviewing and analyzing

information from several large

Australian mining and service companies,

remarked that comments from high-level

mining executives indicated that 98% of

them expected a catastrophic event would

be necessary to drive an industry response

to cybersecurity, at least in that country.

In contrast, following the 2017 Prospectors

and Developers Association of

Canada (PDAC) trade show, six mining

companies formed a group focused on the

cybersecurity needs of the mining industry.

The Mining and Metals Information

Sharing and Analysis Center (MM-ISAC),

as it is known, was established to protect

members against incidents that could

impact safety, environmental sustainability

or operational productivity by sharing

threat and vulnerability information, managing

industry contingency planning, and

providing opportunities for training security

staff and incident response teams.

Moving Beyond Legacy Limits

In a recent blog post on the State of Play

website, an organization spokesperson

explained that the industry’s dependence

on legacy systems, coupled with disinclination

to adopt new software platforms,

is further complicated by exponential

growth in connected devices on mining

networks due to investments in automation

and monitoring technologies.

These legacy systems are often Industrial

Control Systems (ICS), comprising the SCADAs, DCSs and PLCs that control

process equipment. ICSs, in general, were

never intended or designed to be connected

to other systems, but with the advent of industry

digitalization and the growth of IIoT

applications, now they are — not just to

other ICSs, but to company-wide communications

systems and other platforms, thus

expanding potential avenues for intrusion.

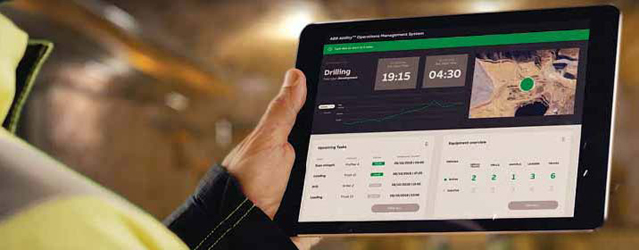

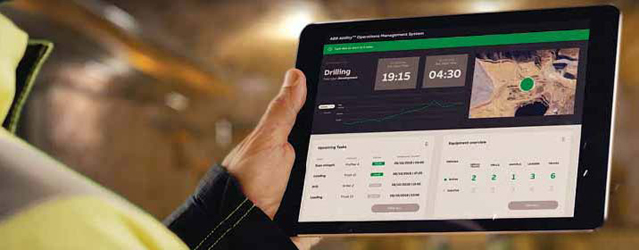

New solutions to maximize the usefulness – and thus the value – of data are being offered to producers at a steady

clip. The key to maximum

New solutions to maximize the usefulness – and thus the value – of data are being offered to producers at a steady

clip. The key to maximum

effectiveness is to find the solution that fits the user’s specific needs and resources for

data utilization, storage and management.

Apala Ray, global cybersecurity manager,

Industrial Automation, Process

Industries at ABB, told E&MJ that as

recently as a decade ago, cyberattacks

targeting industrial control systems were

rarely heard of. The emergence of Stuxnet,

the first computer malware to target

control systems found in industrial

plants, and its role in the now-infamous

attack on nuclear infrastructure in Iran

in 2010 — followed by two high-profi

le attacks on a German steel mill and

Ukraine’s power grid — changed all that.

“Stuxnet was a wake-up call that operational

technology (OT) and not just information

technology (IT) could be targeted

by cyberattacks, as well as ransomware like

WannaCry and NotPetya, not targeted for

OT can create huge impact,” Ray said. “The

estimated recovery cost from the 2017 Not-

Petya ransomware attack to Maersk, for example,

may run to $300 million.

“In the past, many industrial operators,

including those in the mining sector,

believed that because their OT and IT systems

were not connected, they were not

vulnerable. With digital and automation

solutions now offering increased visualization

and interconnectedness, this is no

longer the case.”

Mining cyberattacks typically take the

form of espionage campaigns that target intellectual

property and proprietary information,

or phishing, whereby a user is tricked

into divulging confidential data. Studies

by US Homeland Security show that such

attacks can be mitigated by up to 98% if

industrial operators have put basic digital

hygiene and process controls in place.

These fundamental safeguards constitute

the first stage in ABB’s three-layered

approach to cybersecurity. “Our advice

to clients is to make sure they apply

the latest updated security patches and

anti-virus definition procedures,” Ray

explained. “Use the concept of network

segmentation and make sure you have

a clearly defined back-up and recovery

process in place. The latter is crucial in

allowing a mine, for example, to continue

to operate and avoid costly production

downtime following a cyberattack.

“It is also important to have password

policies and an asset inventory. These

may be basic processes and controls, but

they can eliminate most of the attacks on

industrial automation control systems.

“Cybersecurity is a balance between

risk, usability and cost. Our second layer

of protection involves providing services

to our clients, and the third encompasses

a more mature OT monitoring solution.”

ABB’s Cyber Security Fingerprint service,

for example, identifies critical control

system vulnerabilities at mining facilities

by focusing on three areas: procedures

and protocols; group security policies; and

server and workstation settings. The solution

combines information from an ABB

control system along with insights gained

from interviews with working personnel.

“It is important to remember that cybersecurity

is not a standalone solution:

it is about people, processes and technology,”

said Ray. “We recently worked at a

mine in Sweden that had employed ABB’s

Control System, called ABB Ability System

800xA, in the processing plant for

some time. Using the ABB Ability Cyber

Security Fingerprint the mine’s cybersecurity

policies and how they are implemented

day by day were assessed.”

The solution generates a detailed report

on gaps in the enterprise’s existing

cybersecurity measures and uses an analytics

tool to compare the results with

recognized industry standards.

“Having then assessed whether the

correct procedures and policies are in

place, the Cyber Security Fingerprint tool

finally produces a report that contains detailed

recommendations on how the client

can reduce vulnerabilities, and implement

a focused and sustainable security

strategy,” explained Ray.

However, outdated or poorly managed

enterprise resource planning (ERP) systems

also carry additional risk factors.

Deloitte noted in its Tech Trends 2019

report, “Core modernization seeks to solve

the riddle of how companies with signifi-

cant investments in legacy systems can

extract more value from these systems by

making them a foundation for new disruptive

innovations. As major ERP providers

roll out next-generation platforms designed

to enable real-time transactional processing

and data analysis,” the report’s authors

wrote, “mining companies are facing an

imminent need to update their ERP systems

and make choices on whether to host

their data on premises or in the cloud.”

Whether pursuing enterprise-wide transformation

or making incremental improvements,

mining companies need to consider

the “five R’s” when contemplating core

modernization, according to Deloitte:

Replatform – Upgrade platforms through

technical upgrades, software updates, and

migration to modern operating environments

(such as cloud platforms, in-memory

databases, and virtualized environments).

Revitalize – Layer on new capabilities to

enhance stable underlying core processes

and data. This could include enhancing

usability with digital solutions that improve

employee engagement, adopting

visualization suites to fuel data analysis,

or introducing cognitive techniques to

strengthen reporting and support predictive

and prescriptive analytics.

Remediate – Address internal complexities

of existing core implementations.

This could involve reconciling master data to simplify business processes and introduce

single views of key data, integrating

disparate systems to streamline data sharing

with external partners, or rationalizing

custom extensions and bespoke solutions

to simplify system maintenance.

Replace – Introduce new systems for

parts of the core. This may mean adopting

new products from existing vendors or

revisiting build vs. buy decisions as new

entrants roll out new solutions. Ideally, organizations

will use these pivots to revisit

their needs and build new capabilities

rather than replicating the work habits

associated with their old systems.

Retrench – Do nothing, which can be strategic

as long as it’s an intentional choice.

The State of Play blog also predicted

that “things will get worse” until appropriate

security processes and protocols

are put in place. Things actually have gotten

worse – the COVID-19 pandemic has

added complexity to an already daunting

technological puzzle by forcing companies

to expand remote-worker assignments for

health and safety reasons. As explained by

Microsoft’s Threat Protection group, “The

increasing pervasiveness of cloud services

in today’s work environments, accelerated

by a crisis that forced companies around

the globe to shift to remote work, is signifi

cantly changing how defenders must

monitor and protect organizations. Corporate

data is spread across multiple applications

— on-premises and in the cloud

— and accessed by users from anywhere

using any device. With traditional surfaces

expanding and network perimeters

disappearing, novel attack scenarios and

techniques are introduced.”

A sobering assessment of the elevated

risk of data loss or corruption from workat-

home or other remote locations was provided

recently in a report from data security

company Tessian. The report, titled The

State of Data Loss Prevention 2020, notes

that despite a high level of confidence expressed

by corporate IT leaders — 91%

say they trust their employees to follow

security best practice while out of the

office — nearly half (48%) of employees

admit they’re less likely to.

Tessian said its latest research shows

these key findings:

• 50% of employees say they’re less likely

to follow safe data practices when working

from home because they’re not

working on their usual devices.

• 48% of employees say they’re less

likely to follow safe data practices

when working from home because they

feel as though they’re not being watched

by their IT teams.

• 47% of employees say they’re less likely

to follow safe data practices when

working from home because they’re

distracted.

Modular Mining’s recently released Application Programming Interface (API) is intended to enable enhanced

Modular Mining’s recently released Application Programming Interface (API) is intended to enable enhanced

integration and increased openness through bidirectional data sharing among third-party technologies, such

as

RPM Global’s XECUTE planning software (shown here), and elements of Modular’s IntelliMine portfolio.

In the same vein, writing for the Global

Mining Guidelines Group – a Quebec-based

organization promoting collaboration and

innovation across the mining sector – Sherry

Jacobs, senior manager at Accenture

Security - Resource (Energy), listed several

important issues that companies need to

consider when responding to cybersecurity

threats posed by the pandemic:

• The pandemic has created social engineering

opportunities, including phishing

campaigns; phishing awareness is

key, as cyberespionage and cybercriminal

groups will take advantage of this

condition while it remains active.

• Business Continuity Plans (BCPs), travel

restrictions and remote work policies

challenge enterprise monitoring,

especially for companies that have not

previously executed BCPs. Companies

should advise work-from-home employees

on home-based router and IoT protection

and VPN best practices.

• Companies need advice on how to stratify,

prioritize and outsource information

security operations, and manage infrastructure

and operational maintenance

and growth. In-house security groups

may be subject to increased demand

to maintain or increase coverage under

tighter budgetary constraints.

• Companies should be prepared to execute

monthslong BCPs, including information

security monitoring and response, while

operating under quarantine conditions.

New Problems, New Solutions

The “new normal” — the anticipated industry

transformation of technologies,

workflows and processes powered by digitalization

and boosted into overdrive by

pandemic-related business concerns – will

depend on large-volume data capture from

an ever-expanding universe of sources.

One estimate predicts the number of IoT

connections to rise to 83 billion by 2024,

with the industrial sector accounting for

around 70% of those connections. In

addition to the expansion of IoT/IIoT connections,

vendors are increasingly collaborating

to improve software connections via

interactive data sharing between various

products and platforms. For example:

RPMGlobal and Modular Mining recently

extended a partnership agreement

to deliver a new industry standard Application

Program Interface (API) that

will allow enhanced interaction between

the companies’ products – in this case,

RPM Global’s XECUTE ultra short-term

mining planning software and Modular’s

ProVision High-Precision Machine Guidance

system. The API is a critical part

of a solution which allows information to

automatically flow between systems. The

new industry standard allows applications

and systems to communicate using a language

that is universally understandable.

RPMGlobal chief technology officer

Paul Beesley explained how the process

will work: “The short-term plan, including

the dig polygons, is published from XECUTE

to ProVision. Then equipment status

and bucket positions are sent back to

the planning tool to ensure the plan is being

executed. Those bucket positions can

then also be used to automatically update

the face positions and the schedule.”

Meanwhile, Symboticware and Uptake

announced a partnership to provide mining

companies with an integrated AI and

data science tool to increase the productivity of mobile mining equipment. Symboticware

specializes in real-time data

management solutions, and Uptake is an

industrial AI developer. The joint solution

combines Symboticware’s SymBot

onboard device, which provides comprehensive

data capture from mining fleets,

with Uptake’s Asset IO Asset Performance

Management (APM) to apply AI to harvest

predictive insights from data. Among the

benefits attributed to the combination of

these two products is greater visibility

into assets, offering an ability to collect

data from sensors, store time-stamped

values in an internal database and seamlessly

transmit data for AI analysis.

More recently, Uptake and conveyor-

products supplier Flexco announced that

they had formed a partnership to launch

Flexco Elevate Belt Conveyor Intelligence,

a real-time belt cleaner monitoring system

that uses predictive data analytics to optimize

belt conveyor productivity. Flexco said

Elevate allows for the remote monitoring of

belt cleaners via a wireless platform.

According to Flexco, the solution requires

installation of a device to the end

of each Flexco belt cleaner. Analytics are

immediately aggregated and processed by

Uptake. The information is then wirelessly

transferred to the Flexco Elevate Dashboard.

On a broader scale, vendors in virtually

every sector of digital technology are introducing

new concepts and updated features

on an almost weekly basis. The challenge

for producers is to find the right combination

of products, services and support to fit

their specific new-normal business plans

and environments. Here are a few examples

of what’s recently become available,

starting with basics such a new device

access security platform, and extending

along the full spectrum of industry activity

from exploration to tailings storage.

Device Access Control

Xage Security, a US company that provides

blockchain-protected cybersecurity

solutions for industrial operations, recently

introduced a universal Multiple-Factor

Authentication (MFA) offering intended to

enable industrial organizations to protect

a variety of assets, even those that lack

basic device password protection. Built

to support OT/IoT use cases, Xage’s MFA

solution is claimed to eliminate operational

dependencies to ensure that industries

can protect their assets from attacks, including

the growing wave of cyberattacks

that exploit remote access vulnerabilities.

The company points out that many

industrial operations include machines

with no password protection, or basic

lock/unlock features that lack secure

access control. In the last two years alone,

digital attacks targeting industrial control

systems (ICS) and operational technology

increased by over 2,000%. Xage says

its solution enables MFA for any device

and application, so companies can enforce

authentication with multiple factors

(passwords, one-time token, biometric,

etc.) across their entire system. Operators

can add MFA to all of their assets and enforce

universal multifactor, identity-based,

low-latency access on remote assets, even

over intermittent networks.

According to Xage, authentication and

enforcement are delivered at the edge and

continue to operate even if connectivity

to the center is lost — ensuring universal

tamperproofing without additional dependencies.

As a result, Xage’s MFA solution is

said to capable of mitigating many common

cyberattacks, including password spraying

attacks, password or identity theft and

phishing to plant malware on target devices.

Drill Data in the Cloud

Recognizing that COVID-19 prevention

measures can disrupt conventional geotechnical

studies and exploration drilling

activity, several software developers in

this sector announced accelerated development

and other changes to their cloudbased

solutions in an effort to offer smarter,

more efficient data management in the

current business environment.

Geoscience software company Seequent

said it is speeding-up development of its

cloud-based solution Seequent Central,

aimed at enabling organizations to continue

work on critical, large-scale projects in the

COVID-19 impacted environment.

The company said Central works alongside

Seequent’s other geoscience analysis,

modelling and collaborative technologies

to contribute understanding to subsurface

geoscience and engineering design solutions.

The cloud-based solution allows users

in any location to visualize, track and

manage geological models created for infrastructure

and critical services projects,

in a centralized, auditable environment.

Users can readily access up-to-date information

to manage risk and make better

environmental and investment decisions.

Seequent said one early adopter of the

platform, a Canadian junior focused on

silver production in Mexico, is using its

products effectively. The company, First

Majestic Silver, owns and operates the

San Dimas, Santa Elena and La Encantada

mines and is pursuing development of

its existing mineral property assets.

Seequent said First Majestic uses its

Leapfrog Geo to develop a realistic presentation

of the geology at each site (complex

silver deposits with multiple veins), and

Leapfrog Edge to aid resource estimation –

and when geologic models are changed resource

estimates also change dynamically.

Seequent Central allows the company to

publish models and resource estimates

that are immediately available in real time.

IMDEX, a Western Australia-based

mining technology company, recently

pointed out that drilling contractors

and resource companies impacted by

COVID-19 restrictions can continue to

operate by using cloud-connected sensors

that deliver and analyze critical data.

Despite restrictions disrupting travel and

work, IMDEX said clients can still make

time-critical decisions backed by accurate

data presented in real time.

The company reported that a majority

of its clients intend to keep operating

while working within government-imposed

restrictions and with the priority of keeping

their workers safe. IMDEX said existing

clients already have access to IMDEXHUB-

IQ, a secure, cloud-based portal for

validating field data transmitted from drill

rigs, and recommended that clients use

the current environment to access, review

and analyze data by using IMDEXHUB-IQ

to achieve efficient drillhole and sample

data management from daily reporting and

QA requirements to structural logging, survey

and geochemical analysis.

IMDEXHUB-IQ Global Product Manager

Tara Bennett-Connell said that while

IMDEX HUB-IQ was available free to clients

already using IMDEX tools, some

were still opting to transfer data via email

and USBs. “More secure, efficient and

reliable methods are available, and when

you can’t get access to the data through

those old methods, it’s time to it’s time to

change,” she noted.

IMDEX said its system has been certifi

ed for ISO/IEC 27001:2013, an international

information security standard

recognized in 161 countries.

Managing and Monitoring TSFs

Inmarsat, a provider of satellite-enabled managed connectivity

services for land-based organizations, is now offering two versions

of a Software-as-a-Service (SaaS) solution for mining companies,

aimed primarily at operators that currently have tailings

storage facilities (TSFs) where connectivity infrastructure and

instrumentation is in place, but lack a critical component required

for compliance.

The first of its two offerings, Tailings Insight Cloud, is a SaaS

application claimed to be designed for interoperability, easy integration

and compatibility with many sensors and IoT devices that

make it capable of compiling tailings data from a broad array of

sources. That data is then made visible via a single dashboard view

in real time, accessible from anywhere. It also provides various

ways of visualizing sensor data, while advanced alarm functionality

helps notify key stakeholders of important changes in real time.

The system keeps users informed of sensor health via regular

reporting, while also offering a full audit log, historical data

comparison and journaling capabilities, plus it enables operators

to standardize their tailings management globally, regardless

of sensor type and other instrumentation.

Tailings Insight Plus, built around the cloud application core, is

Inmarsat’s fully managed service. As part of the solution, Inmarsat

provides global satellite connectivity, sensor integration, edge connectivity

in form of LoRaWAN — a point-to-multipoint networking

protocol — as well as ongoing service monitoring and management.

It monitors and manages all of the infrastructure (aside from the

client’s sensors) on an ongoing, end-to-end basis, with a service

level agreement (SLA) tailored to client data collection needs.

Mapping the Path

As technology continues to make it progressively easier for

mining companies to collect and transfer vast volumes of data,

the probability of extracting greater value from that data will

be matched by the likelihood that it could put an enterprise at

greater risk when misused, corrupted or stolen. Companies that

plan to map their own routes to cybersecurity will be looking for

guidelines; here’s a set of recommendations from Accenture, a

professional services company, aimed at helping organizations

become “cyber resilient” to manage complex risk decisions.

Update organizational threat models. Make it a point to revisit

what’s important in the organization by understanding what assets

are required to deliver the business outcome, the relevant

threats and vulnerabilities for the industry and regions, and what

security controls are in place.

Build a strong foundation. Gain visibility over IT and OT systems/

assets, understand their criticality, and recognize threats the

company may be exposed to. Identify high-value assets and harden

them. Prioritize legacy systems. Prepare for the worst.

Pressure test resilience like an attacker. Enhance both red attack

and blue defense teams with player-coaches that use threat

intelligence and communicate closely to provide analysis on

where improvements need to be made.

Employ breakthrough technologies. Automate defenses. Use automated

orchestration capabilities and advanced behavioral analytics.

Be proactive, go threat hunting. Develop strategic and tactical

threat intelligence. Monitor for anomalous and suspicious activity.

Consolidate all threat information in the organization, then

develop the support structures to effectively manage it.

As featured in Womp 2020 Vol 08 - www.womp-int.com