Two heap leach pads are planned for Filo Mining’s Filo Del Sol polymetallic op situated

high in the Andes on the Chilean border. (Photo: Filo Mining)

Designing Leach Pads for the Longview

Experts say studies conducted early should give insight that can be used throughout

the life of the system.

By Jesse Morton, Technical Writer

Whether the miner is operating in lush, subtropical Mexico or the barrens of Nevada, when planning a pad, the long-term goal of closing it in the distant future, without incident, should be the foremost operating motive, they say. That can mean planning for a 500-year storm. It can mean planning on establishing the best possible relations with the surrounding community. Most of the time, however, it means repetitive drilling and layers of lab testing on the ore to get a clear picture of what will happen to it when it is stacked sky high and irrigated. Sky high, in the Andes, is a good starting point.

Polymetallic Op Plans 2 HLPs

Filo Mining is set to build two heap leach

pads at its 100% owned polymetallic Filo

Del Sol Project, in the Atacama Region

on the border of Chile and Argentina.

The orebody is described as “a highsulphidation

epithermal copper-gold-silver

deposit associated with a large porphyry

copper-gold system.” Jamie Beck,

vice president, corporate development

and projects, Filo Mining, described the

deposit as unique. “Often, deposits have

either an endowment of copper or an endowment

of precious metals, gold and silver,”

he said. “At Filo, what is unique is

that we have all three metals in economic

grades, so the challenge here is trying to

find a way to extract the copper, gold and

silver through a leach process.”

In a prefeasibility study, the mine reported goals of eventually producing gold at a rate of 160,000 ounces per year (oz/y), silver at a rate of 8.7 million oz/y, and copper at a rate of 67,000 metric tons (mt)/y. “What is also unique about Filo is we are planning a sequential leaching process,” Beck said. “During the first stage, the plan is to acid leach for the copper on an on-and-off pad,” he said. “After that, the ore is washed, neutralized and transferred to a valley fill facility for cyanide leaching to recover the gold and silver.”

The project is situated high in the Andes, at an elevation averaging 4,800 meters (m) above sea level and subject to high winds much of the year. The foremost issues considered when planning the pads were related to elevation, terrain and climate, Beck said. Temperatures at the site range from -20°C to 5°C. The average year-round temperature is -3° or -4°C, Beck said. “The difference between the summer and winter highs are not that much,” he said. “We plan on it being a cold, windy environment all the time.”

The miner is also planning for permafrost. “That can thaw, especially at the base of any pad and generate deformations,” Beck said. “As a result of that, we have considered a LLDPE (linear low-density polyethylene) geomembrane, that can tolerate the higher deformations. As an additional measure, a stability toe built into the valley fill pad has been designed.” Due to elevation, high levels of ultraviolet radiation can damage exposed patches of geomembrane, which sometimes occurs when ponds and channels evaporate or drain. “Where that is going to happen, we are going to switch to a HDPE (high density polyethylene) geomembrane,” he added.

A “key issue” in designing the valley fill pad, which will use the topography of the area, is “protecting the geomembrane from any puncture due to rock exposure or friction over top of exposed rocks,” Beck said. “There are some steep slopes and some exposed rock. We are planning to use some geotextile as a cushion were needed to protect the geomembrane from puncture.” The on/off pad will be built using cut and fill and backfill “to develop a flat foundation for the geomembrane,” Beck said. “No protective underliner is going to be required.” The overliner material for both pads will be a permeable gravel, possibly granite, Beck said.

Stacks will max out at 7.5 m on the on/off pad. “The total area there is about 670,000 m2,” Beck said. “The load is pretty small and didn’t drive the design of the liner system.” “The valley fill pad we are planning on building is in two phases,” he said. The first phase will accumulate 1.6 million m2 of ore, followed by an expansion upward of an additional 630,000 m2 of lined area. “The plan is to reach heights of about 100 m to get a total volume of 160 million m3,” Beck added. The mine is expected to move some 60,000 tons per day. “Process recovery is expected to be 80% for the copper, 70% for the gold, and 82% for the silver,” Beck said. The project could span 14 years.

Headlining milestones for 2019 center on drilling and testing. “We’ve got deep drill holes going in this season,” Beck said. “We’ve identified a good portion of the oxide deposit, which this heap leach plan is addressing.” The orebody sits atop a “big sulfide deposit,” he said. “Before we get too far down the line on a construction decision, we want to understand more about what is lying underneath.”

At the core of the advice Beck has for miners in a similar situation is thorough testing to arrive at a comprehensive understanding of the orebody. “You can learn so much about things through your metallurgical test work,” he said. “You want to make sure you are doing a significant and substantial number of tests so that you’ve got confidence that ultimately when you get up there and build this thing and put it into production, you are going to achieve the production targets.”

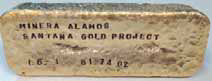

Gold Mine to Build HLP in Stages

Minera Alamos Inc. told E&MJ it will likely

build a gold heap-leach pad system in

stages at its Santana gold project in Sonora,

Mexico.

Exploration started at the 8,500-hectare

project in 2008. Drilling revealed

“the mineralization was open along the

strike and to depth.” The promising

zones were described as having low-sulfidation hydrothermal breccias with quartz,

calcite and some iron minerals. Drilling

highlights included sizeable intersections

near or at the surface with grades of about

a gram per mt (g/mt), and including some

grading at almost 2 g/mt.

The ponds have to be capable of handling whatever runoff is possible. Santana is subject to what Koningen called a three-months rainy season. “The worst thing you can do in that situation is build a huge leach pad with nothing on it,” he said. “And then the rainy season comes, and you are collecting the water over a very large lined area.” A better scenario is to have multiple levels of material in place at the start of the rainy season, Koningen said. “The ore in the heap acts as a sponge to absorb rainfall during large rain events, and by not having large unused areas of the heap helps us with our solution management by minimizing surges into the ponds,” he said. “We typically evaluate these scenarios as part of our engineering design using a water balance model.”

The biggest pad-design issue at the company’s mines often centers on slopes, he said. “If you look at most of the work that has been done over the years, the weak point, as far as friction angels are concerned, is between the liner and the clay below the liner,” Koningen said. The goal is to build the pad at an angle that does not exceed a certain threshold, which, he said, was typically less than 9% to 10%. “Stability can often be further improved through an additional more-shallow buttress on the order of 2% to 3%, typically near the toe of the leach pad,” Koningen said. “Otherwise, you have to stage it and bench it so you can have steeper areas.

The pads at Santana will likely be underlined with local clay. “In our experience in Mexico, there have been enough local clays available that you can have an underlining compacted clay liner,” Koningen said, “and then an HDPE or LLDPE liner on top so you get your two layers of containment, or what is referred to as a composite liner.” To further protect the liner, Koningen said he plans to limit the amount of liquid allowed to build up on it. “I am not a fan of building in liquid containment into your pad designs where you start to get a meter or two meters of liquid above the liner because that is counterproductive,” he said. Optimal is a “pretty minimal amount of liquid above the liner,” Koningen said. “Then, even if there is some minor punctures and things like that, it will easily seal off with the underliner material.”

Some of the initial test work focuses on the geomechanics of the ore and the possible percolation rate. “We do early testwork, looking at permeability and the fact that, if you go up 50 or 60 meters, how much liquid can still get through,” Koningen said. He advised it is crucial to complete studies on the geomechanics of the ore early on. “Figure out what crush sizes you really need and have a good handle on whether you’ve got mineral constituents in there, like clays and other things like that, that are going to cause problems with permeability,” he said, “because most of the problems you have with your pad are related to that.”

Vanadium Op Plans Acid HLP

Prophecy Development Corp. is planning

to run an acid heap-leach system at its

Gibellini vanadium project in Eureka

County, Nevada, USA, using technology

and processes similar to those employed

by nearby gold miners, according to company

leadership.

Gibellini is planned to be an open-pit

operation with an initial capital cost of

$116 million and producing 9.65 million

pounds (lb) of vanadium pentoxide per

year at an average all-in sustaining cost

of $6.28/lb for up to 14 years. The total

inferred resource is 52.3 million tons.

The mine is expected to move roughly 3.4

million tons of material per year.

Ron Espell, vice president of environmental

and sustainability, Prophecy Development,

told E&MJ the ore is exposed

at the surface at a “very low” strip ratio.

“It is just sitting there,” he said.

As part of the PEA from 2013, when the project was owned by American Vanadium, samples from trenching totaling 18 tons were sent to a third party for pilot heap-leach testing. There the ore was crushed and dried and put through 12-in.-column and bottle roll tests. The average recovery rate was roughly 72% from a head grade averaging 0.29%. “The final pregnant-strip solution was 6.1% vanadium, 250 g per liter sulfuric acid, with approximately 2% iron and aluminum,” Prophecy Development reported. Espell said the company is in the process of redesigning the operation as it was originally planned by the previous owner. Included in the redesign is the heap leaching system. “Looking at the geotechnical work and the heap leach pad, I think the previous American Vanadium plan for the heap was 200-ft tall,” he said. “All that stuff is being evaluated right now.”

The primary challenges to be addressed in the redesign arise from the differences between the plans for the heap leaching system for Gibellini and the ones in place by neighboring gold mines. “No. 1 is it will be the first heap leach for vanadium in the world,” Espell said. “The biggest challenge is it is an acid heap-leach pad and an acid heapleach process,” he said. “The challenge there, from an environmental perspective, is we are in Nevada, and Nevada is gold country.” Gold miners in Nevada use cyanide for heap leaching. “As an industry, we have cyanide heap leaching down to child’s play,” Espell said. Cyanide is unstable and breaks down easily, helping with smooth, safe, regulatory problem-free closures of mine sites, he said.

To answer that question, Prophecy Development hired “one of the best geochemists,” Espell said. Another question for the geochemist is how to maximize use of the acid. “The idea is that the acid is going to be our most expensive reagent cost for the project,” Espell said. “We want to save that acid.” One plan being considered is to reuse it. “As we finish a cell, we actually rinse the acidity out of it and capture that acid to be able to use for the next cell’s leaching,” Espell said. “By doing that, we are removing that acidity so that at closure, we don’t have an acid drain-down solution to have to deal with. It makes closure much simpler.”

In routine operations, the miner will add a step to the end of the leaching process for each section of the heap. Normally, after the barren solution leaves the mill, acid is added to it in the plant before it is routed back to the stacks. Instead, at Gibellini, the barren freshwater will be pumped “back to the top of the finished heap to flush the remaining acid water out to enable recovery of that acid” for use elsewhere on the heap, Espell said. The mine is planning to use a geomembrane system that is standard for mines in the area. “In Nevada, the liner systems are really well-defined in the mining regulations,” Espell said. “It is called a water pollution control permit, which is a zero-discharge permit, and you have to obtain it from the state in order to run any heap leach pad. It is going to be virtually identical to a gold heap-leach pad.”

When it comes to challenges posed by climate, Prophecy Development will apply lessons learned from history. Espell, who has worked for a couple of mines in the region, including McEwen Mining’s Gold Bar project and another operated by Barrick Gold, said that winter leaching there now has been mastered. “In the early days of gold heap leaching, we had problems until we all figured it out,” Espell said. “We used rain bird sprinklers. In the winter time, we’d create these tremendous ice castles. Then we got smart as an industry.” The answer was to go to subsurface drip emitters. “That did two things for us,” Espell said. “It allowed us to leach through the wintertime with no effect because the solution is underground. The other thing it did from an environmental perspective is it didn’t allow for any pooling or ponding of those leach solutions on top of the heap leach pad that birds could get into and have wildlife mortalities.”

Espell described the rock as friable. “It is not super competent,” he said. The mine will likely use a strategy he saw deployed at Gold Bar. “I recall that one had a clay issue,” he said. “The ore had to be agglomerated and then leached.” To maintain percolation at Gibellini, “we’ll have to do the same thing,” Espell said. “It will have to be an agglomerated particle. That is a classic thing out of the gold industry where if you need to stabilize the ore, you agglomerate it.”

Potential concerns about possible needs for special overliner or underliner materials are de-prioritized currently due to the expected limited size of the mine and stacks. “We have gold heap leaches out there that are in excess of 600-ft tall,” Espell said. “The industry standard liners are fine with stuff like that. This is going to be a baby compared to a gold heap-leach pad.” Further, the geology and terrain of the area, described as “very mild and gentle,” ensures “you couldn’t pick a better place to have a heap leach pad,” Espell said. “We’re sitting on top of 400-plus ft of alluvial gravel,” he said. “There is limestone hills above us and basically nothing but neutralizing-capacity limestone underneath the leach pad.”

The culture of the county also ensures the site is primed for success, Espell said. “Eureka County is the mining county,” he said. “The regulators here are very strategic in their approach to problem solving.” The mine will benefit from a new federal program designed to streamline the state environmental permitting processes, Espell said. “The new secretarial order, No. 3355, demands that an EIS can be now no more than 150 pages, and they can’t take more than a year to complete,” he said. “That is a huge opportunity to get this thing permitted quickly.”

Gold Mine Closes Trouble-free HLP

Cerro San Pedro, New Gold’s open-pit

gold and silver heap-leach operation near

San Luis Potosí, in Central Mexico, is in

the process of closing shop.

The mine, formerly one of a handful

owned by the company in North America

and Australia, is operated by the subsidiary,

Minera San Xavier S.A. de C.V. Operations

began in 2007. In 2015, it produced more than 100,000 oz gold. Active

operations concluded in June 2016. Residual

leaching continued and the mine

produced 65,000 and 34,000 oz of gold

in 2016 and 2017, respectively.

The pad there is a success story, Angel Chung, general manager of the mine, told E&MJ. From the outset, the system has performed as intended, he said. “Up until closure, there has been no evidence of instability, sinking, leaks, mud slides or cracks.” The single-use pad was built in phases, Chung said. “The first phase was built in 2006-2007 and the last one in 2014,” he said. “First ore load was placed in 2007 and the last load in 2016.” The underfill is a clay of low permeability. “It was moisture controlled to provide the required compaction specs with a minimum of 25 cm height,” Chung said.

The channel collection ditch liner is made of 2-mm-thick HDPE. A 1.5-mm LLDPE liner lines the rest of the pad. Overfill is 0.75-in. crushed barreno, begonia, and hospital limestone stacked to a height of at least a meter in most places, Chung said. “Ore types and quantity, haul truck capacity; and total estimated weight were taken in consideration for the design of the overliner fill,” he said. Terrain slope and stability were also determining factors, he said. Further, “electrical resistivity testing was done to understand presence of water and cavities below the surface.”

The ore is described as porphyry oxide, porphyry mixed and porphyry sulfide, Chung said. It was hauled and dumped using 50- and 100-ton haul trucks. “Ore has been placed and stacked conforming to the planned 70-m height on average, amounting to a total of 100 million tons during the whole mine life,” he said. Climate was a significant factor considered when designing the pad and system, Chung said. Described as semi-arid, San Luis Potosí, located on an interior steppe, has an average annual temperature of about 17.9°C and receives on average a little more than 34 cm of rainfall per year. “A probabilistic analysis of the 100 years rain event was taken into consideration for the collection pipe, channels, and ponds design,” Chung said.

Chung gave E&MJ a bulleted checklist a miner doing a prefeasibility study for similar heap leach pad could use. The ones he had not alluded to yet centered on human relationships. “Build great relationship with authorities and regulators, and establish good communications,” Chung said. “Build good relations and communications with the local communities. Help those communities with employment, and develop people.”

Along those lines, currently the mine is “performing a gradual and inclusive closure process based upon best international practices,” he said. “We want to leave a legacy for the community adjacent to the mine, and to safeguard the good name of New Gold.”