Every three years, Messe München hosts

the bauma trade fair in Munich. Billed as

the world’s leading sector event for construction

machinery, building material

machines, mining machines and construction

equipment, the exhibition space

totals 640,000 m2, making it the largest

trade show on earth.

For 2019, Messe München expects to

have 3,500 exhibitors from 60 countries.

Unlike other large equipment fairs, bauma

has dedicated a portion of its program

to mining. Mining represents roughly

20% of the exhibition. The mining sector

has its own hall: C2. According to Messe

München, a total of 578 exhibitors indicated

they are involved with mining,

extracting and processing raw materials.

Visitors reviewing exhibitor information

will note the mining symbol and the

phrase Mining Inside. Miners hoping to

make the most of their time, however,

will need to narrow the field. For them,

E&MJ offers a selection of “must-see”

stands. What follows is a compilation of

announcements leading up to the event.

ALLU’s attachment crushes as it loads.

ALLU’s attachment crushes as it loads.

ALLU Offers Mobile App

In addition to its existing state-of-the-art

screener/crusher equipment being exhibited

at the show, ALLU will also be introducing

new products and solutions, including

a new Mobile App with new functions

aimed at helping improve productivity,

job-site safety and customer service.

The new Mobile App is the latest development

for ALLU’s communication

system. It provides an intelligent digital

solution for customers and operators to

obtain accurate and timely operational

information, thereby maximizing safe

and productive use of ALLU equipment.

Through easier and improved contact

functionality, customer support is also

enhanced through the new features of the

app. There will be live demonstrations

throughout the show from the ALLU stand

(FN.1021/2 in the open area, north).

Reliable Conveyors for Rough Terrain

The BEUMER Group (Hall B2, Stand

413) will provide information on their

efficient transport solutions for the mining

industry. Overland conveyors and pipe

conveyors transport various raw materials

over long distances and often through

rough terrain. This is generally faster,

more cost-efficient and environmentally

friendly than trucking.

High angles of inclination and tight

curve radii are not a problem. BEUMER

Group relies on camera-equipped drones

for the planning, projection, implementation

and documentation of these systems.

Using special software solutions, the system

supplier evaluates the aerial photographs

photogrammetrically to generate

digital terrain models.

The BEUMER product range also includes

stackers and bridge reclaimers

for storage yards, whether with or without

blending bed systems. These stack

bulk material and guarantee a maximum

blending effect. Users can also efficiently

homogenize large quantities of different

bulk materials and bulk material qualities

and ensure the uniformity of the raw materials

used. For efficient loading, BEUMER

Group supplies ship loaders with fixed

booms and extendable telescopic belt

conveyors.

The Brokk TE160 rock drill attachment.

The Brokk TE160 rock drill attachment.

Brokk Introduces Rock Drill Attachments

As Brokk’s machines have become more

technically advanced and market demand

for mechanization has increased, demolition

robots are increasingly used for a

more varied range of applications requiring

additional tools.

Over the last few years, to meet this

demand, Brokk has developed new attachments

and upgraded its machines to

work well with a wider range of tools. One

of those is a rock drill attachment. These

are customized and fully integrated with the

control and operation of the Brokk robots.

The range has been extended with the powerful

new TE 326 drill attachment used on

the new Brokk 300 and Brokk 500 models.

This creates a complete range of rock

drills for Brokk machines, from the small TE160 used on the compact Brokk 110

to the powerful TE360 used on the biggest

Brokk machines. All drill rigs are

characterized by their exceptional performance-

to-weight ratio, the company said.

Technology Solutions for Lubricants

Evonik will present two of its leading

technology solutions at bauma (Hall A3,

Stand 244): DYNAVIS technology, which

optimizes the viscosity of hydraulic fluids;

and industrial gear oil formulations

based on NUFLUX technology, which

perform as well as synthetic based fluids,

at a lower cost, the company said.

Changing from a standard hydraulic

fluid to one formulated with DYNAVIS

technology generates many benefits, including

increases in machine productivity

and improved fuel efficiency, according

to Evonik. Additional benefits include

the machines operating more efficiently,

reacting better, needing less frequent

service, and suffering less wear and tear,

ultimately extending their service life,

according to Evonik. And, this pays off

quickly, most notably in extremely demanding

applications, while also assuring

higher returns, lower energy consumption

and reduced CO2 emissions.

Companies who focus on mining, road

construction, demolition or earth-moving

have realized increased profits, with peak

efficiency gains reaching up to 25%, according

to Evonik. A current test project

on a Hitachi EX1200 hydraulic excavator

at a mine in the Kuznetsk Basin, Russia,

demonstrated that the use of DYNAVIS

technology yielded 7.9% growth in coal

extraction as measured in bank cubic meters

per hour.

Oils formulated with NUFLUX technology

are largely equivalent to synthetic lubricants,

and even surpass them in some

respects. In fact, during a recent field trial

with pump gear in South Africa, a higher

degree of efficiency was measured with

aerators that promises to pay off. This

made the plant’s decision easier to fill 26

of their gears in the water treatment system

with NUFLUX formulated oil, saving them

approximately EUR 17,500 per month.

Hella’s RokLUME projects a red danger zone on the

Hella’s RokLUME projects a red danger zone on the

ground around the excavator.

Using Lighting Systems to Improve Safety

Lighting and electronics expert HELLA

(Hall A5, Stand 436) has developed the

VISIOTECH projection technology and has

already launched four products to help

in these situations: The LED Projection

Module, the warning lights SL60 LED,

Module 50 LED Spot and — particularly

for mining — the RokLUME S700 Red.

The LED Projection Module was specially

developed for original equipment

and projects an exclamation mark as a

warning symbol on the ground near the

machinery. For the SL60 LED and Module

50 LED Spot warning lights, a special

lens optic allows the light rays to converge

so much that a strip-shaped warning line

or warning spot is projected on to the

ground. This application serves to warn

other vehicles or pedestrians of an oncoming

vehicle. The lines projected in front of

a vehicle can, however, also be used as a

means of simpler vehicle navigation.

The RokLUME S700 Red LED warning

light utilizes the same principle and

projects a wide red marking on to the

ground, thus highlighting the danger

zone around the vehicle. Thanks to its

powerful light output, the warning light

can also be used on vehicles with high

mounting positions and is particularly

suitable for mining vehicles.

Liebherr will unveil electrically powered hydraulic shovels at bauma.

Liebherr will unveil electrically powered hydraulic shovels at bauma.

Electric-powered Excavator

Liebherr will give bauma attendees a unique

chance to experience its latest innovations

first-hand, which range from construction

machines, material handling, mining and

components. Visitors can look forward to

seeing many new technologies and other

practical innovations at Liebherr’s 14,000-

m2 outdoor stand (809-813) and its indoor

stand (Hall A4, Stand 326).

For the mining division, visitors will

see demonstrations of the R 9200 E electric-

drive excavator. This will be a world

premiere for a machine in this class. Together

with the R 9200 E, Liebherr-Mining

will present the new T 236 diesel

electric-drive truck.

At the fair, Liebherr Components will

also reveal the demo version of an app

that shows the extensive functionality of

all Liebherr’s condition monitoring components,

from diesel engines to energy

storage, hydraulics, transmissions and

slewing bearings. In the future, this will

enable machine manufacturers to inform

fleet managers, service personnel and

machine operators about the condition of

their components.

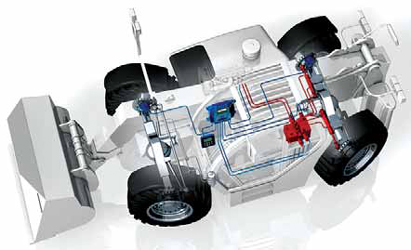

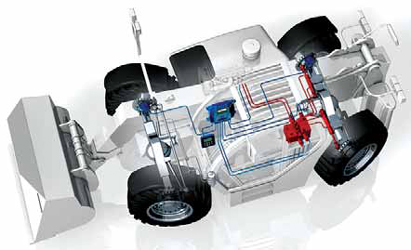

Mobil Elektronik wants to equip mining machines with rear-axle steering.

Mobil Elektronik wants to equip mining machines with rear-axle steering.

Using Lighting Systems to Improve Safety

Rear-axle Steering Systems

Electrohydraulic steering systems for rear

axles have been standard in commercial

vehicles and complex construction machinery,

such as cranes, for many years.

In the case of commercial vehicles,

the use of electrohydraulic auxiliary steering

is primarily to ensure compliance with

the legal requirements. Without a steered

rear axle, the legally defined minimum

turning radius cannot be maintained.

Most other machines, such as twoaxle

loaders, usually have hydrostatic

front-axle steering. It is obvious that

these machines could also benefit from

rear-axle steering.

Mobil Elektronik (Hall A3 /Stand 115)

can equip these machines with the same

features that are already standard in mobile

cranes. Operation will be easy and

convenient. The steering mode can be

changed at any wheel position. The synchronization

of the axles with each other

is done automatically.

The Metso MX cone crusher.

The Metso MX cone crusher.

Advances in Mineral Processing and More

Along with new crushing and screening

solutions, Metso (FS.1111/2) will unveil

a groundbreaking innovation for off-highway

trucks, enabling mines and quarries

to haul more with less. This major product

launch will expand Metso’s offering

into completely new territory and help

customers reach a higher payload while

lowering their operating costs.

In addition, Metso will showcase a

broad range of equipment, wear and

spare parts as well as services designed to

help make operations more efficient and

assets work harder. The solutions to be

featured will include cone crushers and

slurry pumps. The Metso MX cone crusher with patented

Multi-Action crushing technology designed

to cut the operational costs of crushers

and to provide more uptime compared

to traditional cone crushers, the company

said. Since its introduction in 2017, Metso

has sold 50 MX crushers worldwide.

The Metso slurry pump range is optimized

for maximum uptime and reduced

operating costs. The slurry pump maintenance

slide base offers fast, safe and easy

wear component change or pump inspection.

Leaving the suction and discharge

pipe undisturbed during inspection, the

entire rotating assembly and motor configuration is slid back.

Rock Bolting Systems

Normet’s line of auxiliary equipment for

underground mining applications is well

known. The company’s Rock Reinforcement

business line has developed new

innovative products that can help solve

some of the toughest challenges.

The D-Bolt, for example, is widely used

as part of the ground support system in

some of the largest and deepest mines.

The company’s locally anchored, self-drilling

hollow Rock Bolts can be used in combination

with its construction and mining

chemicals, where conventional systems

are not delivering the desired results. In

addition, Normet is devoting time and resources

to further develop the next generation

of rock reinforcement systems, creating

even safer underground environments.

The D-Bolt represents the new generation

of energy-absorbing rock bolting

systems, specifically designed for efficient and reliable rock reinforcement, in

both squeezing and burst-prone strata

conditions. The technology is based on

a smooth steel bar with a number of anchors

along its length.

The newest addition to the D-Bolt family

is the Connectable D-Bolt, a system that

is extendable through specially designed

couplings. This bolt type is especially effective

for smaller profile spaces where

there is a need for a longer bolt anchoring

offering an alternative to cable bolts.

For areas where ground conditions are

very difficult and demanding, Normet designed

an innovative, patented bolt combining

the features of the Self Drilling Anchor

(SDA) and D-Bolt. Normet produces

two types of anchor taking into consideration

design and load bearing capacity. For

the North American mining market, Normet

designed the bolt to reflect Nevada mine

conditions, the SDDB — Nevada type.

The anchor is a 2,400-mm long Self Drilling

Hollow Bar made from a single piece seamless tube with a 32-mm diameter. The

thread is ISO R32 rolled with uneven length

from each side. The material for the SDDB

Nevada type has been carefully selected to

respond to a customer’s inquiry for yield

load and elongation at break. The bolt is

typically used for single length applications

although it can be extended with couplings

to reach the desired length where necessary.

This anchor utilizes a drill bit and longer

root threaded section for anchorage.

Scania will display five trucks at bauma.

Scania will display five trucks at bauma.

Scania’s V8 Celebrates

50 Years

Scania will display five construction

trucks in total: four inside the exhibition

hall and one outside it. What they all have

in common is the robustness and productivity

level for which Scania is well known.

At bauma, Scania is also showing connected

engines for equipment, vehicles

and vessels that facilitate fleet monitoring

and optimized uptime. This service is

based on the vast knowledge Scania has

gained from having connected 350,000

buses and trucks.

The company is also celebrating the

Scania V8 turning 50. It made its debut

back in 1969. “In its latest edition, it

is still the pre-eminent solution, always

delivering like no other,” Alexander Vlaskamp,

senior vice president of sales and

marketing. “Regardless if it’s emotion or

logic behind a purchase, the V8s never let

our customers down.”

Conveyor Components

Superior Industries (Hall B2, Stand 107),

an American builder of crushing, screening,

washing and conveying equipment,

said its presence at bauma 2019 will be

three times larger than previous editions.

In addition to wet processing equipment,

Superior will display conveyor components,

including the Chevron Pulley, a

V-shaped wing pulley that deflects oncoming

rocks; the Moxie Roll, an idler made

from a composite blend, which are 50%

lighter and at least three times quieter

than steel; the High Performance DT Idler

for improved performance in high capacity

applications; and the Exterra SFL Dual

Belt Cleaner, a primary and secondary

scraper sharing one mounting pole.

The lizard mobile-stacking bridge from thyssenkrupp Industrial Solutions can be used for stacking ore on

The lizard mobile-stacking bridge from thyssenkrupp Industrial Solutions can be used for stacking ore on

the leach

pad and tailings.

Mobile-stacking Bridge

thyssenkrupp Industrial Solutions will present

its new mobile stacking bridge, “the lizard.”

This unique solution for heap leaching

and dry tailings stacking combines two

proven technologies — the conveyor bridge

and the tripper car — in a new way. The lizard

decouples the crawler-mounted tripper

car from the conveyor bridge, enabling it to

be controlled independently of the bridge.

Decoupling the tripper car from the

conveyor bridge has several advantages:

The transitions between the bridge segments

are easier as there is no stress

from a traveling tripper car on top of the

bridge. As the loads on the bridge sink,

the overall construction of the bridge outweighs

the additional chassis and structure

of the tripper car. This way the product

saves weight and costs, according to

the company. In addition, a larger dump

height and longer outreach are possible.

“Especially with longer conveyor bridge

systems the lizard pays off with lower investment

cost and less fatigue issues on

the bridge structures,” said Stefan Ebert,

global product lifecycle manager. “Since

the tripper car is not traveling on the bridge,

the loads for dimensioning the bridge are

significantly reduced,” said Burhan Osmani,

engineer at thyssenkrupp Industrial

Solutions and the inventor of the lizard.

Operators benefit from a slimmer,

lighter bridge structure, lower bridge

height, smaller bridge crawlers and lower

ground pressure. The same lightweight

design can also be used for the reclaiming

bridge. Fatigue issues otherwise caused

by cyclic loads from the tripper car are

completely eliminated, the company said.

This significantly reduces maintenance

requirements and increases availability.

A key advantage of the lizard is its

multi-crawler chassis. thyssenkrupp used

its expertise in this area to develop a

unique solution that improves productivity.

A multi-crawler chassis with no override

control, the so-called “float system,” is attached

to the tripper car. The double crawlers

with no steering cylinders ensure unrestricted

maneuverability in all directions.

The system can be attached to any crawler

to avoid the large turning circles of conventional

gearing systems. “To be able to

flexibly control the mechanically independent

multiple crawlers is a game changer

in mobile mining equipment,” said Paulo

Costa, head of mining systems.

The float gearing system allows the lizard

to be operated flexibly: When a stacking

row is completed, the tripper car is at

either the front or rear end of the bridge.

Before moving to the next stacking row,

the tripper car has to turn its crawlers

through 90° in the direction of bridge

movement without impacting the performance

of the system. In this way, the

tripper car and the stacking bridge move

backward or forward as one stacking system

depending on the stacking plan.

Tsurumi KTZ series submersible

Tsurumi KTZ series submersible

pumps.

Tsurumi to Launch 2 Pumps

No two mining projects are the same,

which also applies to the dewatering systems.

Two new pumps by pump manufacturer

Tsurumi offer greater scope to come

up with ideal solutions. With its innovations

KTZ415 and KTZ615, the Japanese company

has outdone its series of professional

drainage pumps for difficult applications.

The 615 is the new top model of the

KTZ series that now comprises 15 models.

Thanks to a motor output of 15 kW, the

aggregate achieves up to 2,800 liters per

minute (l/min) with discharge heads of almost

40 meters (m). In contrast, the 415

with the same motor only pumps 2,000 l/

min, but up to a maximum height of 55 m.

Both submersible pumps can cope

with heavy particulates with grain diameters

of up to 12 mm. The pumps are

pressure-resistant to a submersion depth

of 25 m and have a pressure port with a

diameter of four (model 415) and/or six

(mode 65) inches on the outside thread.

Tsurumi will be displaying many other

pump models (Hall A6, Stand 338), as

well as another innovative that it still under

wraps but which will be launched in

2019. Engineering enthusiasts can also

look forward to exhibits of cutaway pump

models and live wet applications.

Smaller Surface Miners

Wirtgen’s 220 SM 3.8/220 SMi 3.8 surface

miner selectively mines raw materials up to

a cutting depth of 350 mm and a uniaxial

compressive strength of 35 megaPascals

(MPa). Thanks to its 3.8-m-wide cutting

drum designed specifically for soft-rock

mining, the compact surface miner achieves

maximum productivity at low operating

costs and is perfect for use in small to large

mining operations, according to Wirtgen.

The 220 SM/SMi’s cutting drum has

been designed specifically for demanding

windrow applications in soft rock, such

as coal or salt. Maximum cutting performance

combined with the ideal use of engine

power and low specific fuel consumption

allows raw materials to be mined in

an extremely cost-effective process. Six

different adjustable cutting-drum speeds

ensure that the machine can be perfectly

adapted to the material being extracted.

This leads to a significant reduction in

pick wear, minimal diesel consumption,

and increased productivity, which translate

into an impressive daily output and

low cost per ton of extracted material.

Wirtgen’s 220 SM 3.8/220 SMi 3.8 surface miner selectively mines soft rock.

Wirtgen’s 220 SM 3.8/220 SMi 3.8 surface miner selectively mines soft rock.

In surface mining, the continuous

availability of the machine and its safe

operation are of critical importance. This

is why the surface miner’s components

are designed to achieve a long service

life, even under extreme conditions. For

example, filters in all circuits and a pressurized

hydraulic reservoir ensure maximum

purity in the hydraulic system and,

as a result, safe operations. The clean

oil in turn prolongs the service life of the

downstream components and thus increases

the availability of the machine.

The 220 SM/SMi also meets occupational

safety requirements in surface mining

thanks to the standard-equipped ROPS/

FOPS operator’s cabin. The cabin features

additional soundproofing and vibration

isolation, allowing the operator to work for

several hours without the risk of fatigue.

The ergonomically designed and clearly

arranged controls are integrated into the

armrests of the driver’s seat, and all of the

machine’s key functions are logically incorporated

into the multifunctional joysticks.

This means that the operator can operate

the machine intuitively in just a few steps

and fully concentrate on high-precision

mining. The state-of-the-art, fully air-conditioned,

large-capacity cabin also features

generously sized windows, giving the operator

a direct view of the cutting edge and

with it, the results of their work.

More information about the trade fair is available at www.bauma.de

As featured in Womp 2019 Vol 03 - www.womp-int.com