The Dry Gravity Separator processes a bed of material

instead of a flowing film.

Development of Dry Gravity Separator

A retirement hobby may lead to mineral processing breakthrough

By George Rodger

Fast forward to 2004, a dry pilot plant design engineer (the author) was seeking a challenging retirement hobby. The hobby selected was to devise a dry concentration method that eliminated the fatal flaws of the North African experience. The process equipment requirements would be a high unit area of production capacity, no vibration and low energy requirements. Two possible designs were considered.

The first design was for a hindered settler based on wet counter flow sizing. With five years of dry silica milling experience, it was felt that low-pressure air could replace water as the fluid medium. This design would have a high unit area of capacity, require no vibration and would have low energy requirements.

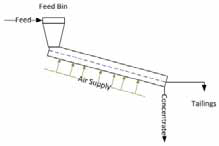

The second design for consideration was to adapt dry air-gravity conveyors. With this type of conveyor, fine dry particles are fluidized with low-pressure air, which forms a flowing film. The challenge was to determine how these conveyors could be modified to segregate, concentrate and recover heavy minerals. The flowing film aspect could be a limiting production rate factor. But, it was felt that limitation would be overcome by processing a bed of material instead of a flowing film.

The second design was ultimately selected for investigation. The redeeming feature being the unit could be built out of plywood in a garage. And the stainless- steel medium could be purchased and fitted to the prototype profile. The first design was beyond the designer’s ability, capacity and retirement budget to build such a prototype unit in a garage.

The particle size range selected for the modified air-gravity conveyor prototype was 100% passing 50 mesh (300 microns) down to 96% retained on 270 mesh (53 microns). Within this particle size range, air gravity conveyors are able to convey minus 50 mesh particles. Removal of low-terminal velocity minus 270 mesh particles would ensure a relatively dust free operation. The basic, length to width geometry, for air-gravity conveyors was followed for all of the dry gravity separator prototypes. Briefly, this is a generalized diagram of the dry separator prototype.

In 2005, prototype fabrication was started for a junior mining company. That company held a Barite deposit where a source of water was not available. By the end of one year, the company had run out of research funds. TM Engineering of Burnaby, British Columbia, had fabricated the SS medium and feed bin for the dry separator prototype. They saw a mining industry niche for a dry process and offered to support development by providing shop space and modification support.

Development continued on Barite until an oil industry drilling mud specification (4.1 SG) could be produced. Then work was switched to base metal ores. During this time, the price of gold increased significantly, so the objective was switched to gold ores. Since then, development work has focused entirely on producing a dry gravity gold separator.

Two binary standards were employed for prototype development. The standards were made up of No. 70 silica sand, with various concentrations of magnetite (5.2 SG) to simulate base metal ores; and with tungsten- carbide/cobalt (14.6 SG) to simulate gold ores. Because magnetite and tungsten- carbide/cobalt have magnetic properties, process samples could be separated, the fractions weighed and metallurgical results calculated. No assaying was required, which reduced development costs.

Development Program

A multiyear development program (this

was after all a retirement project) went

through four generations of dry gravity

separator types. In each case, the basic

operations of feeding, segregation, concentration

and recovery remained the

same. Along the way, many technical and

mechanical problems were resolved. For

example, small changes in fluidization air

pressure proved to be sensitive to the operating

requirements. Initially, dry feeding

was difficult to deal with. Once the minus

50 mesh fines were aerated and fluidized,

it became a difficult fluid to meter. This

was resolved with a guillotine-type feed

gate. The height of sands in the aeration

feed bin was in effect a hydraulic head,

where the feed rate varied according to the

depth of material in the bin. Since gravity

separations work best with constant feeds,

this was resolved by converting the aeration

feed bin to a constant head bin.

The segregator, concentrator and recovery sections went through several geometric, mechanical and slope changes. More than 200 runs were required to establish a viable prototype separator. The most challenging of all problems was to establish an effective mineral/metal recovery method. In a number of cases, what seemed to be the correct way often turned out to be the reverse of that thought process.

At the end of development work, low weight base metal and gold rougher concentrates with metal recoveries in the low to mid 80% range were consistently achieved. Breaking the size distribution range up into two or three smaller particle size ranges, will bring recoveries up to the low 90% range. The Sahara gold pilot plant operation demonstrated this is feasible.

Development Trial Results

This submission follows development

work first reported in the June/July 2014

issue of the Canadian Mining Journal in

an article entitled “Waterless Wonder.”

That article described the initial trials to

produce a dry gravity separator.

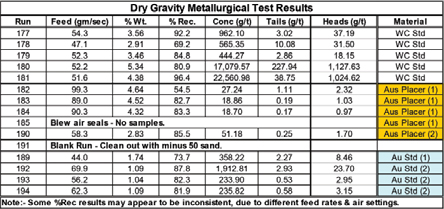

This article describes the results for the binary tungsten-carbide/cobalt standard, two gold standards, and for two placer samples. Gold standard rougher concentrate metal recoveries in the low to mid 80% range were consistently achieved into 1% to 5% rougher concentrate weights.

Of the two binary gold standards, the first was made up of silica sand and portions of a 1.1-g gold nugget. That nugget was filed down to less than 50 mesh sized particles, which were conditioned to round-off edges. The second binary gold standard was made up of silica sand and 35 and 50 mesh particles of placer gold from Washington. A total of three placer standards were evaluated with feed grades varying between 23.7 g/mt and 2.95 g/ mt. The tailings from the 23.7 g/mt high grade run (No. 192) was used as the feed grade (2.95 g/mt Au) for the subsequent gold run (No. 193). Rougher concentrate weights varied between 1% and 1.7% of the initial feed weights. Rougher metal recoveries (including the media residuals) varied between 81.8% and 87.8%.

When development of this dry prototype concept was initiated, a gravity separator processing a bed rather than a film was envisaged. This was done to increase the productive capacity/unit area rate. However, as development work evolved, gold results showed that only a flowing film would provide acceptable metal recoveries. The limiting factor was the process residence time, which was determined to be 0.7 seconds. For acceptable metal recoveries, a residence time of 0.7 seconds was too short of a time interval to effectively process a bed of material.

Scale-up for Commercial Operations

Wet spiral concentrators have tonnage

rate unit area values of 17 mt per hour

(mt/h)/m2. And wet plane tables (Rand

Leases 1950s practice) have values of 16

to 24 mt per h/m2. The dry gravity prototype

has a tonnage rate unit area of 1.6

mt per h/m2, roughly one-10th of that for

the wet spirals and plane tables.

When the dry-gravity prototype design was set up, the length to width ratios for air-gravity conveyors was followed. This gave the dry gravity prototype a 15:1 length: width ratio. A scale-up rule of thumb for gravity separators is go longer for grade increases and wider for higher tonnage rates. Since the length of the prototype was producing good concentrate grades; the scale-up decision was taken to increase the width and retain the length. Aerated bin feeders are available to accommodate these width increases. And, increasing the width brings tonnage rate area values up to commercial levels.

Should precious metal mineralogy for a gold deposit be favorable for dry-gravity concentration, lower capital and operating costs favor gravity-concentration circuits over other unit operations. Should gold values be present within complex sulphides; low weight dry-gravity concentrates could be recovered, sold or transported to other locations for additional processing.

Commercial grades of precious metal values that extend into the minus 270 mesh fines, where terminal velocities are too low for gravity recovery methods, can be processed and recovered by employing iron ore pelletizing practices. Those fines will be in a Blaine surface area range that lends itself to balling and cold bond pelletizing. Those pellets can be sold or transported to a water source area for conventional treatment.

For most size distribution ranges, this will amount to less than 10% of the initial feed weight. A way forward for the flowing film dry gravity separator will be to build a dry pilot- plant facility to confirm the dry concentration concept and generate plant scale design data. The longer production runs will increase the confidence needed for this dry gravity concept. And, with a three-product air classifier in the pilot plant circuit, shorter particle-size ranges, which maximize metal recoveries can also be evaluated.

The Technology Readiness Level has reached a point where prototype development is complete and proof of concept has been demonstrated. The next step will be to fabricate a scaled-up 4-mt/h production model for pilot plants and for commercial operations.

The production model will have a process capacity that is equivalent to spirals or plane tables, with no vibration and with low energy requirements. In this regard, the flowsheet will be similar to the high daily-process-rate iron ore spiral plants operating in Northern Quebec. Where a large number of spirals, eliminate 95% of the feed in a first pass, and with two cleaning steps produce shipping grade concentrates. For gold ores, dry tabling of the cleaner concentrates will produce a refining grade product for bullion production on-site.

A dry gravity separator will require complimentary dry operations that crush, grind, size, convey and upgrade concentrates. Tailings products will require cold bonding agglomeration methods to avoid wind-borne losses to the environment. These additional operations employ equipment that is currently available in the iron ore, industrial minerals and recycling industries. The future should be bright. Water is a limited resource, but air is not. And the process air will be a catalyst that does not become an environmental hazard.

George Rodger is a consultant with Rodger Mineral Services. He can be reached at +1(604) 942-8075.