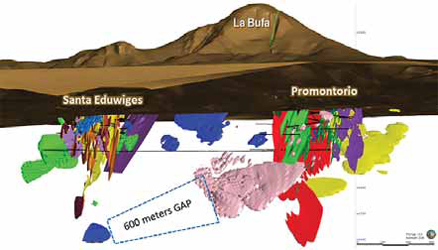

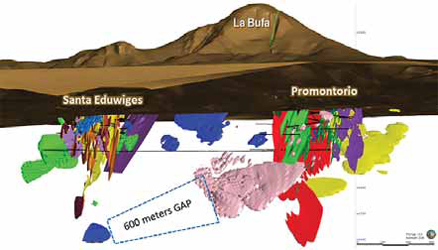

A 3D model shows the mineralized ore bodies at the Cusi mine in Mexico.

Sierra Studying Expansion at Cusi Silver Mine

Life-of-mine capital costs of the expansion program are estimated at $104 million. Sierra Metals is pursuing ongoing exploration programs and expects to continue to grow the mineral resources at the Cusi mine. Mechanized bench-and-fill mining will be introduced to achieve sustainable mine production of 2,700 mt/d. Improved productivity will be accompanied by improved safety, as the requirement for man-time spent in stopes will be significantly reduced. Head-grades are expected to reduce from the current 201 g/mt silver to 161 g/mt at 1,200 mt/d and 145 g/mt at 2,700 mt/d.

Cusi mine production is processed at Sierra Metals’ Mal Paso plant, approximately 44 km from the mine. The plant is based on a conventional crushing-milling- flotation circuit that produces commercial quality lead/silver and zinc concentrates. Mineral is delivered from the Cusi mine to the plant in 20-mt trucks.

In line with proposed increases in mine output, processing capacity at Mal Paso will be increased to 1,200 mt/d in 2019, and a new plant with a capacity of 1,500 mt/d is proposed for construction at Cusihuariachi to come online mid-2021, bringing total capacity to 2,700 mt/d. The proposed plant at Cusihuariachi is significantly closer to the Cusi mine than the Mal Paso plant, and the shorter haul distance is expected to translate into an operational savings of $4/mt.

The Cusi property is located 135 km southwest of Chihuahua. Epithermal mineralization has been mined in the area since its discovery in the early 1800s.

Eight mineralized zones are recognized at the property. The zones are up to 10 m across and include silicified faults, veins and breccias. Veins typically range between 0.5 and 2 m wide, dip steeply, extend 100 to 200 m along strike, and extend up to 400 m depth.