Technology Improves Shovel Productivity

Proper positioning prevents poor performance

Inefficient shovel cycles, difficult material identification, unclear progress line definitions, and extensive manual surveying are some of the challenges that shovel and excavator operators face on a regular basis. High-precision machine guidance solutions can help resolve these challenges by using GPS signals to provide equipment operators with impressive positional accuracy.

Modular Mining Systems’ ProVision Machine Guidance solution, which was released for excavators 20 years ago this year, provides positional accuracy to the centimeter. The system also employs high-precision elevation control, which helps to improve bench height management, ramp accuracy, and current floor elevation accuracy, while drastically reducing ore boundary staking and manual progress surveying. The high-precision elevation control also allows shovel operators to remain on grade as they dig into the face to virtually eliminate rework due to under- and over-cutting.

Machine guidance technologies that facilitate accurate material identification and delineation, like the ProVision solution, can also help mines improve their shovel productivity by reducing misrouted material. In addition, the system’s real-time availability of geographical data improves adherence to the mine plan, and quickly notifies operators of plan deviations to further improve accuracy and productivity.

Challenges With Current Spotting Methods

Typical truck spotting methods employed

across many mine sites today are often

inefficient. As the shovel operator maneuvers

his bucket into the desired loading

location prior to a truck’s reversal, he

creates an extension in the overall cycle

time, resulting in productivity loss. This

“spotting time” is a non-productive and

unnecessary portion of the loading cycle,

and is exacerbated by the time required

for the truck operator to reverse to the

correct loading spot and reposition as

necessary. In addition to contributing extra

time to the loading cycle, the shovel’s

resulting hang time consumes unnecessary

energy in its requirement to hold a

full bucket while waiting for the truck.

These spotting methods can also create potential safety risks from truck-shovel impacts. “The truck-shovel exchange is one of the most frequently occurring processes in a mine,” said Charles Orr, product manager for Modular’s machine guidance systems. “It can occur more than 800,000 times per year at a large site. Even if an impact occurs in only a fraction of those interactions, the potential safety risk and equipment damage that often results can be significant.”

By reducing the spotting segment of the loading cycle, even by seconds, mines can potentially increase their overall production capacity by millions of tons annually.

Improving the Excavation Load Cycle

The excavation load cycle plays a critical

role in the surface mining production process,

making it an ideal target for optimization.

In addition to the potential overall

production increases, improving the load

cycle also enables mines to:

• Minimize shovel hang time;

• Optimize shovel swing angle;

• Maximize trucking capacity; and

• Increase compliance to plan.

Achieving this ideal load cycle is often more easily said than done, however; haul truck maneuvering efficiency at shovels, crushers, and dumps can vary dramatically with operator skill. This variability has led mines to employ standard operating procedures geared toward the site’s lowest capability level to ensure a safer production. While such traditional practices as bucket spotting and single-side loading can help reduce the risk of truck-shovel impacts, they often do so at the cost of productivity. As the shovel hang time that results from these traditional practices increases, the productivity of both the shovel and truck decreases.

Operator-assist Technologies for Load Cycle Optimization

Operator-assist technologies can help optimize

the load cycle to significantly improve

the productivity of both shovels and trucks

by efficiently guiding haul truck operators

as they reverse toward the shovel loading

position, without guidance from the shovel

operator. The Guided Spotting system, part

of Modular’s ProVision Machine Guidance

solution, is one such technology, and can

help optimize the excavation load cycle

by potentially equalizing the performance

of all operators to a capability close to (or

even beyond) that of the most experienced

operator. The system’s high-precision guidance

and real-time communication and integration

between the shovel and truck enable

precise guidance to a predetermined

loading point, governed by the shovel.

The Guided Spotting system is designed to improve both shovel productivity and operator safety awareness during the truck spotting and loading process, and utilizes visual displays mounted near-side mirrors to leverage existing practices, rather than seeking to replace those practices with technology. The symbology utilized on the visual displays is operator-friendly and easy to interpret from the peripheral line of sight, helping even the least-skilled operator to potentially perform as efficiently as the most-skilled. In addition, the Guided Spotting system provides the truck operator with real-time feedback regarding his exact location, relative to the desired spotting point.

The system allows the shovel operator to specify his desired loading point(s) for both single- and dual-sided loading and integration between the ProVision solution and Modular’s DISPATCH Fleet Management System facilitates optimization of the next available truck assignment to further decrease the excavation load cycle time and increase fleet production capacity. The shovel operator can also update or change the loading points without assistance from the central office or survey team.

After extensive successful field trials

at a large mine in North America, the system will be released later this year. It has

the potential to:

• Increase shovel productivity by 4% to

35%;

• Contribute up to two to eight additional

loads per hour;

• Reduce swing time by up to 15%;

• Reduce shovel energy consumption due

to hang time; and

• Achieve additional gains by eliminating

re-spotting.

Technologies to Increase Shovel Uptime

Shovels are some of the most important

pieces of equipment on a mine site, but

maintenance for them is often overlooked;

since many haul trucks use a fleet management

system that helps to centralize incoming

data via telemetry, they can provide

more information for maintenance teams to

immediately act on. Key performance indicators

(KPIs) for maintenance often place

emphasis on fleet availability. Since mines

typically have more trucks than shovels in

their fleets, truck maintenance is often the

fastest and easiest way to fulfill this KPI.

But from a production standpoint, having

a plethora of available trucks means very

little if no shovel is available to load them.

Additionally, shovels receive a high-operational priority, which can conflict with maintenance initiatives. Prolonging scheduled maintenance might help sustain production in the short term, but often results in increased and unscheduled downtime later if the prolonged maintenance results in a failure or increased wear and tear to the shovel.

Planned shovel maintenance requires

careful time management. Modular’s MineCare

Maintenance Management solution

helps maintenance teams prioritize

objectives from a condition-based approach,

rather than a time-based one, relying

on OEM and custom-defined alarms

to identify potential issues before they

result in catastrophic damage and costly

downtime. The MineCare solution is OEM

agnostic, providing interfaces to the most

OEMs in the industry, and allows users to

establish custom alarms based on time

series data and OEM events. The solution

captures such time series data as:

• Stress monitoring for shovel boom, arm

and frame;

• Engine and related energy consumption;

• Hydraulics and electrical systems; and

• Digging conditions and blast quality.

The MineCare solution’s ability to collect an abundant amount of data from each of the shovels across a site’s fleet, and translate that data into actionable information, can help maintenance teams decrease their unplanned shovel maintenance to further increase productivity.

As the mining industry continues to rebound, mines will continue to look for ways to optimize efficiencies wherever they can. Since shovels and excavators play such a critical role in the open-pit mining process, their productivity, uptime and availability become excellent optimization targets. Through machine guidance, operator assist, and maintenance management technologies, Modular Mining Systems provides the value mines need to optimize their equipment, empower their people and drive production.

This article was written and submitted by Modular Mining Systems. For more information, contact www.modularmining.com.

Evaluating Performance: Hydraulic Excavators vs. Rope Shovels

At Haulage & Loading 2017, University of Alberta Professor Tim

Joseph presented the results of ongoing studies that compare

the dig performance for a hydraulic excavator versus an electric

rope shovel. They evaluated similar mining-class machines in

terms of the energy required to excavate a unit quantity of the

same material from a mining face. One of the initial findings

was that the energy per unit excavation quantity for rope shovels

and hydraulic excavators working in the same muckpile are, in

fact, identical. This proved the fact that the amount of energy

to excavate a unit quantity, regardless of the excavating tool, is

constant. The energy required is related to the material to be

moved and not the machine.

But, these results do not indicate whether one primary excavator is better than another; nor does it represent the total picture driving the selection of one excavating tool over another. The total cost of ownership (TCO) including capital (plus sustaining capital), operating and maintenance (O&M) costs, time, availability and utilization (productivity and efficiency of use) must also include the qualitative decisions regarding mining method and the mode of application; much of which is driven by the geological, operating and environmental conditions that are highly site specific.

Another parallel study of rope shovel and hydraulic excavator performance focused on availability, productivity and life cycle costs (with a sub-focus on maintenance costs) for up to 60,000 operating hours per machine, where data was available. Each machine’s performance was assessed by operating hours, maintenance activity impacting availability, and productivity per cubic meter (m3) of bucket capacity as a comparison normalizing factor, regardless of excavator size. Cost of ownership, including capital outlay, operating and maintenance costs including but not limited to spare parts, fuels, lubricants, electricity and consumables, were considered.

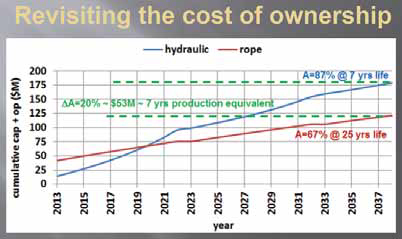

The researchers pulled together costs for both types of machines and projected that over the expected life of the machine, 25 years for a rope shovel and nine years for a hydraulic excavator. “If the [TCO] was compared on a production equivalent basis, the availability difference between the rope shovel and hydraulic excavator amounted to 20% or $53 million over seven years,” Joseph said. “The rub, however, is that everyone calculates availability differently.”

To establish an availability standard, they conducted a massive survey of surface mines and plotted availability looking at distribution. Taking the mean, they found an 85% correlation for the availability standard developed. “If we compare the data for the two types of machines, the availability of the rope shovel is roughly twice that of the hydraulic excavator,” Joseph said. “Looking at mines sites with both types of machines working in similar mining conditions, it was close to double, confirming the results of the study. This would be a practical reference tool for engineers to predict availability as a function of hours.”

The O&M costs for a hydraulic excavator are higher than a rope shovel on a production-equivalent basis. As the life of the hydraulic excavator deteriorates, the rope shovel holds constant, Joseph explained. “The rope shovels are production machines, while the hydraulic excavators are moving about the mine,” Joseph said. “In true productivity comparisons, they should be much closer, but they are not because of how they are used. “Production wise, the biggest difference is primarily found in the dig cycle time,” Joseph said. “It seems as though operators take more time with hydraulic excavators in face loading applications to improve the bucket’s fill factor. The difference between 48 seconds for a rope shovel compared to 60 seconds for a hydraulic excavator makes a huge difference over the life of the machine.”

Maintenance costs for a hydraulic excavator are higher. “The difference in maintenance costs between a rope shovel and a hydraulic excavator is 5.5 times,” Joseph said. “This is important for the equipment selection process. With exception of the electrics and the electronic controls, rope shovels haven’t changed much, Joseph explained. “On the other hand, the systems that have changed on the hydraulic excavators have changed a lot,” Joseph said. “These machines are more complex, which requires more training and that slows the process. Over the course of 25 years, we see an availability of 67% for the rope shovel and 85%-87% for the hydraulic excavator, but the hydraulic shovel is not always loading.”

The results of the research also indicated higher production rates by excavator of similar capacity and age. In general, electric rope shovels, with higher initial purchase cost, exhibited lower service cost per m3 of capacity, becoming overall more cost effective within 5 years (~30,000 hours) of operation over the hydraulic excavator counterpart of similar capacity.