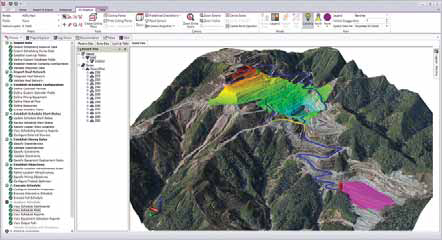

Hexagon Mining’s scheduling solution Minemap 3D will be a centralized hub for both planning and operations. It

features optimization functions and a virtual reality component. (Photo: Hexagon)

Software Solutions for Planners

Pressured to Nix Costs, Handle Change

When reality in the pit departs from the original plans, some software solutions

empower the control room to react quickly and still meet energy cost reduction goals

By Jesse Morton, Technical Writer

What Sammut is describing summarizes the “technical challenges” that, along with declining ore grades and prolonged bureaucratic machinations for getting new projects approved, could up costs and constrain certain metals and minerals supplies into 2018, according to Reuters.1 That trifecta puts increased pressure on planners to prioritize efficiency, Sammut said. “Mining companies are looking for lowest cost production,” he said. “How can we make this whole process of blasting, loading, hauling and crushing the most economic we can?”

In the right context, that question posits the two greatest challenges currently faced by planners: 1) How to ensure reality in the pit jibes with plans and goals; and 2) How to ensure those plans are laser targeting optimum efficiency.

Efficiency, of course, is defined differently depending on what office one is in. A new paradigm being discussed among Sammut’s colleagues in academia and consulting has operations being streamlined for energy efficiency, and thus targeting optimum fuel burn and kilowatt usage, Sammut said. “It has energy-balance at the heart of it,” he said. The way it works is the miner determines what process will be the most expensive, energy- use-wise, and puts that at the center of plans. For example, under this paradigm, control room workers might hatch mine design, plans and schedules around crushers and haulers, major consumers of energy. Everything from haul routes to blast fragmentation plans would be crafted with minimizing total energy use, and thus total energy costs, in mind. The rest comes secondary.

Admittedly, Sammut said, this is the way of the future. “The energy idea has never really been applied to the mining side,” he said. “That is a very sensible thing to start to do.” To do it, however, he warned, “you need an understanding of the whole process.” He said too often plans, especially initial plans, are formulaic, not dynamic, which hamstrings the miner’s ability to be proactive. “Right now, there is a kind of impression that one case fits everything,” he said. “You need to be looking at every case individually. Every mine is different.” Some of the basic assumptions routinely cooked into plans and schedules should be thoroughly assessed for applicability, he said. “This is what some are taught: This is the formula. Throw all the numbers in, and make it work,” Sammut said. “Real life isn’t like that.”

A handful of mine planning software solutions suppliers say their offerings can enable the new paradigm of dynamic planning, maximized efficiency and real life. Their solutions are pitched as lightning fast, easy to use and intelligent. And in many ways, these solutions are democratizing the planning process by increasing transparency, enabling information- sharing, facilitating communications, and leveraging advanced algorithms that automate previously time-consuming manual processes.

Centralized Planning

Hexagon Mining is field testing an upgrade

to Minemap 3D that will make it a

centralized hub and a single information

source for both planning and operations.

The company is planning at least two updates

next year, each one making more

planning tools accessible to operators and

more equipment data accessible to planners.

Currently, those tools and related

data are siloed between two groups.

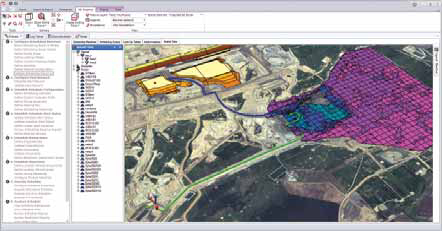

For example, mine design and planning, block modeling and drillhole management is done in MineSight, which is effectively the engine for a suite of mine management programs. Hexagon’s fleet management system, Mineops, is one of those programs. Currently, planners create a file, such as a mine design, in MineSight that has to be first exported and then imported into Mineops. Minemap 3D is currently a mode within Mineops that allows operators to track and monitor in real time, among other things, equipment movements.

After the initial release, planned for early 2018, operators will be able to access MineSight tools through Minemap 3D. The reverse is also true. Planners will be able to, through Minemap 3D, access the real- time data generated by the equipment. This means that revisions made to the mine design could be based on real-time data coming in from the field and also will be accessible instantly to operations. “The clients have been asking for a way to make it easier for them to share haul network information, and if we need to make an update in the FMS side of things, they can make that change really quickly and send it to the planners so they can update their forecasts and update their cycle times and get more accurate predictions,” said Seth Gering, product manager. “It has never been a very easy process getting that information back and forth. Minemap 3D is going to solve that problem.”

That, the company said, will speak to the two primary planning challenges by facilitating data and information sharing and by automating certain processes, such as optimizing haul routes.

By using a universally accessible centralized information source, the miner can cut training time and expenses, Gering said. “When you change management between people that are always moving around in a site,” he said. “If they are used to looking at one system, and they are all looking at the same one, then training becomes easier as well as operator introduction and communication.”

Being able to access MineSight tools will ensure swift adjustments when reality sabotages plans. If, for example, muck sampling mandates revisions to an orebody model, the changes to the model and in turn to mine design, plans and schedules would be instantly accessible through Minemap 3D, Romero said. “The system will automatically update with any change that the planning tool produces in future versions.” That will also grease the information flow in the opposite direction, from operations to planning, he said. For example, if a shovel goes down, control room personnel can react instantly. “If I send all of your data in real time and I tell you that that shovel is going to be down for the rest of the shift, as a planner, what are you going to do?” Romero said. “With the new set of data coming in real time to a planner, you can do some adjustments and pull a loader and identify if the revised plan is going to be suitable. “The planner can consider a different distribution of the equipment to achieve the plan.”

The end result, Gering said, is increased transparency throughout the planning process. “We are starting to knock down that barrier to where the planners and the operators are seeing the same information and being able to use that real- time information to make better plans.”

The upgrade will also feature algorithms that automate haul truck route adjustments, minimizing down time, which increases time utilization of the equipment and minimizes unnecessary fuel burn. Currently, Minemap 3D employs what Hexagon calls an optimizer. “If a shovel is going faster, the optimizer is going to send more equipment to that shovel,” Romero said. “If the shovel slows down, the optimizer is sending less equipment to that particular shovel.” With one of the upgrades, Minemap 3D will automatically edit road networks according to, for example, new inputs introduced by planning. “If we put a background satellite photo that contains all the elevation data and on top of that we put the roads, the roads’ match to the reality of the terrain is going to be perfect,” he said. Or, if a road is suddenly closed due to an event, the optimizer will automatically reroute traffic to the most efficient route, he said. “Basically, customers want to have their roads automatically updated based on what is happening on GPS position or based on what is happening where the shovels are digging or the trucks are dumping,” Romero said. “This is why we are pushing a lot to launch this thing to the market because this is in high demand.”

Optimizing Fuel Burn

Leveraging genetic algorithms, Maptek’s

open-pit scheduling solution, Evolution

Origin, enables the control room to make

optimizing truck hours, and thus fuel

burn, a primary objective of scheduling.

Contrast that with historical software

packages that “have always made this a

post-process,” said Robert Slade, senior

vice president, sales. “Once you know

you’ve mined so many tons from this

bench, and you know that you are hauling

it to this dump, then that is historically

calculated after you’ve scheduled

your resources and you’ve scheduled your

trucks.

“That it is a post-process means that the planner, at the time that he is scheduling these resources, after he has run his schedule out, comes back and starts to calculate what that energy load would be in terms of required truck hours.” Traditional software packages used by schedulers to calculate truck hours typically rely on faulty assumptions, such as, for example, a static dump site mass centroid, Slade said. “If you are doing this as a post-process, you are making again very crude estimates as to how much energy you are using,” Slade said.

Ideally, a scheduler seeking to target energy efficiency would model: 1) the most efficient hauler routes; and 2) the actual state of the waste dumps, which are dynamic, building over time, he said. “We are building these waste facilities upward,” Slade said. “To overcome gravity, you have to use mechanical energy and all of the efficiency downgrades that you get in producing that mechanical energy to lift that 300 metric tons (mt) up to the top of that dump.” It is critical, he said, to calculate “exactly what level you are going up to, how far out, and all of those functions that will go back to a fuel burn calculation.”

Evolution Origin does both. First, it can predict “exactly where I mine from on the bench, and which bench and from which block and to which active dump face is most efficient,” Slade said. It does this by looking at the equipment specs, such as fuel burn and rim torque curve. It then looks at the availability and utilization of the truck. It also considers roads, represented by a digitized polyline. “That is the last input,” Slade said. “It is a digitized set of pathways, which have associated attributes of grade and rolling resistance and other variables such as pulling up to an intersection.”

Second, it creates a dynamic model of the dump site that can calculate the exact “point where it is more efficient energy- wise to start a new ramp to the next level than it is to haul 1,000 feet across this rough dump surface at this level,” Slade said. “Through using the same concept of a block model to represent an orebody, we do the same thing on our waste dump. We have a series of blocks which represent discreet locations for our haulage estimate.”

Optimum schedules and routes are deduced by a series of linked computations, dubbed genetic algorithms. “Now we can run thousands and thousands of sequences, and, using genetic algorithm optimization, we can throw away the ones that are not good and seed the next population with the best,” Slade said. Over time, the weakest scenarios are culled and the ones with the best potential are rendered. The processing is done in the cloud in a fraction of the time it takes historical linear programming to do anything remotely similar, he said. “The genetic algorithm approach is a far better solution than historical linear programming for finding an optimized, practical schedule,” he said. “The problem becomes so huge that a linear programming optimization is no longer capable of solving it.”

Most scheduling solutions can be delivered within an hour. If, for example, muck sampling results mandate revisions to the orebody model in Maptek’s mine planning solution Vulcan, the new model can be exported from Vulcan and uploaded by Evolution in roughly a half hour. “You substitute in the new model in 30 minutes, and we’re scheduling again,” Slade said. “That is a very efficient turnaround at the scheduling and planning point.”

Anticipating Volatility

RPM Global’s, end-to-end mine scheduling

solution, Open Pit Metals XPAC

Solution (OPMS), was designed with the

understanding that “mining is volatile industry,”

said Alun Phillips, planning and

scheduling solutions product manager.

“No two days are ever the same, and

conditions can change in an instant.” Accordingly,

OPMS, having automated many

of the scheduling process, empowers the

control room to respond to real-time data

lightning fast, he said. “OPMS has been

engineered to process data faster than

any planning and scheduling solution on

the market, and can produce an updated

mine schedule within five minutes,”

Phillips said.

Advanced automation empowers the control room to be dynamic when reality crashes plans, he said. “It draws heavily on mathematical modeling to control mining sequence, model haulage, identify the best waste placement strategy and optimize the mines final products, both to maximize value and control blend,” Phillips said. “When a key input parameter (such as a geological block model) changes, the scheduling engineer does not have to repeat the entire scheduling from the beginning. They must simply select the modified inputs and re-execute the scheduling process.”

That process leverages not only automation, but a centralized scheduling database to eliminate redundancy and accelerate results, Phillips said. Deliverables include optimized schedules, cycles, haul routes, dump plans and downstream processing models.

And that speed, accuracy and ease-ofuse represents a dramatic departure from some of the competitor’s offerings. “Traditionally, when an engineer gets a new block model, it’s really back to the drawing board,” Phillips said. From there, they would normally repeat a number of tasks to ensure the scheduling reserves correctly reflect the changes, he said. “Only then could they start rebuilding the schedule from the beginning,” Phillips said. “Even when the changes are not significant, over time, they will start changing things like stockpile balances and material presentation at the operational faces.” Simply accounting for these small changes will force them to repeat much of the original scheduling exercise, he said.

Scheduling flows almost effortlessly from there, he said. “The user has already defined the targets, the equipment and its capabilities, the scheduling objectives, the size and location of the stockpiles, the characteristics of the processing plant, all the factors they decided to incorporate into the scheduling model,” Phillips said. “Re-running the scheduling process will rebuild the schedule from scratch, using the existing configuration applied to the updated reserves.”

OPMS generates models and scheduling scenarios that can be oriented to the markets, such as grade cut-off strategies, or to overall operational efficiency, Phillips said. “While identifying blocks that carry a lower cost can be valuable in some instances, OPMS applies a number of other strategies that goes beyond this simplistic approach,” he said. For example, while the mining schedule is being generated, it simultaneously creates a detailed waste dumping schedule. “The filling sequence is controlled by rules and constraints that are similar to the mining rules, along with control over the location specific materials can be placed within the dump,” Phillips said.

By modeling the state of both the mine and the dumps throughout the schedule, OPMS can evaluate every available dump location before assigning destinations to loads, Phillips said. “This includes a full haulage analysis of the haulage options available at that point in the schedule, so the destination with the shortest cycle time, rather than the closest, can be selected,” he said. “This is done with an industry- leading haulage simulation library that’s endorsed by all the major mining equipment manufacturers.”

OPMS also features tools that model downstream processes for the purposes of improving efficiency and production. “The Product Optimizer models the behavior of the mines entire processing facilities, considering both material characteristics and feed rate,” Phillips said. A holistic approach allows OPMS “to identify the optimum processing strategy and the most practical schedules for the material being mined.”

As user-friendly and fast as it is, OPMS should not be misconstrued as a black box that mysteriously cranks out optimal schedules, Phillips said. “Rather, it is a tool that allows engineers to pose complex problems, analyze the outcomes and iteratively refine the model.”

And the field results have met customer expectations, he said. In one example, Phillips said, an iron ore miner used OPMS to rapidly implement scheduling adjustments after stockpile sampling from an exercise highlighted potentially viable ore that had previously been marginalized based on the preset cut-off grade strategy. “The planning engineer noticed that one of their large stockpiles contained some high-grade material that had been excluded because of it had a very high phosphorus grade,” he said. “To explore this opportunity, he introduced a separate stockpile for this specific type of material and allowed the schedule to draw from it in periods where the ROM phosphorus grade permitted.” The amended strategy allowed resulted in an additional 10 million metric tons (mt) over the mine’s life.

In another example, a gold miner reported that using OPMS reduced the amount of time invested in scheduling by almost an order of magnitude. “Oceana- Gold uses OPMS at their Macraes gold mine in New Zealand and continues to experience significant benefits, such as an 85% reduction in time to produce schedules, and a run-rate of 5 minutes to arrive at updated mine schedules as mining conditions change,” Phillips said.