Safety in the pit depends heavily on equipment operators being aware of all that’s taking

Safety in the pit depends heavily on equipment operators being aware of all that’s taking

place around them — which

can be difficult due to the dynamic nature of the work

environment. The latest systems from leading fleet management

specialists aim to alleviate

the problem through better use of onboard sensors and ‘smarter’ software algorithms.

A successful work-site safety program

might be described as a collection of good

choices, selected from an ever-growing inventory

of systems, products and services

and shaped by a company’s resources and

commitment. At some time in the past,

those choices may have mainly been influenced by how external regulations defined workplace safety. Nowadays, the

list of “influencers” related to safety has

expanded to include considerations based

on workforce age, local culture, literacy

and social license to operate, as well as

concerns that might have once been fringe

issues such as exposure to excessive vibration,

fatigue monitoring and the behavioral

problems associated with fly-in, fly-out job

arrangements, to name just a few.

The ultimate safety objective for many,

if not most, major mining companies is

the eventual removal of as many workers

as possible from the pit, stope or plant to

reduce the potential risk level for harm in

what usually has been, and probably will

continue to be for most on-the-ground personnel,

a challenging work environment

shaped by a changing regulatory framework.

For the near future, however, workers

generally will be needed at the point of production,

and corporate safety policies may

be based on how much personal responsibility

companies are willing to assign to

those individuals to ensure their own safety

and that of the workers around them, and

at what point the company should turn to

technology to take those decisions out of

workers’ hands. In this article, E&MJ takes

a look at some of the digital technology

available that can be used to tailor a safety

system to fit a company’s specific needs.

Expensive, But Essential…

Ensuring worker and asset safety is not a

cheap endeavor, but the lack of an organized,

effective safety program can be even

more financially damaging — as illustrated

by a saying that’s popular with safety

professionals: “If you think safety is expensive,

try [paying for] an accident.” Although

costs are always a concern in any type of

business venture, mining companies seem

increasingly willing to bite the bullet and

spend the money needed to ensure worker

well-being. But most companies, particularly

midtier and smaller companies with

finite resources, want to do it “their way”

and not just blindly follow the guidance

of regulators and consultants interested in

checking-off a series of boxes on a list.

Consequently, safety system flexibility

and scalability are of increasing importance,

and although data is now the lifeblood

of industrial performance-measurement

systems — and there is no lack of

data sources, ranging from by-the-second

inputs from remote sensors on a machine

to long-term production trends generated

by mine management systems — the key

concern for most companies is how easily

and effectively data can be used to identify

potential problems or opportunities and

make well-informed decisions.

E&MJ spoke with Jeff Brown, CEO of

Focus FS, to get an idea of what mining-

industry end-users may be looking

for in the safety-software market. Brown,

formerly with IBM, started the company,

based in Newfoundland, Canada, in 2012

and recently announced a two-year collaboration

agreement with DMC Mining

Services that will employ Focus FS’s mine

safety software product, ShiftProcess, to

develop innovations and improvements in

DMC’s safety effort. DMC Mining Services

is a unit of KGHM Polska Miedz S.A., and

is a major North American underground

contractor with capabilities ranging from

shaft sinking and raise boring to mine development

and operation.

The agreement between Focus FS and

DMC is the second step of a two-phase

relationship between the companies and

will include the rollout of Focus FS systems

across DMC to enhance leading

indicator and predictive analytics, along

with risk management, and to provide

digital H&S management systems that

span the organization from corporate level

down to each individual operating site.

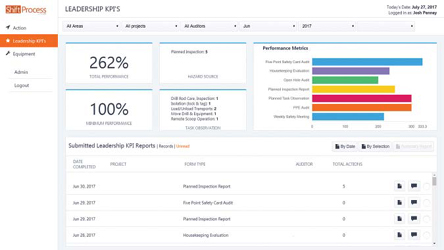

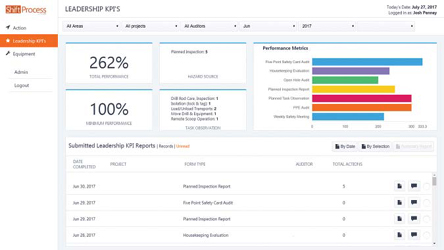

The Main Management Dashboard of ShiftProcess displays performance as it relates to compliance across

The Main Management Dashboard of ShiftProcess displays performance as it relates to compliance across

the

mine site and the organization. Total Performance measures all work performed against a set of targets

(may

exceed 100%), minimum performance reports against the minimum compliance target (would not exceed

100%).

Dashboards are specific to the user and their role.

Brown said ShiftProcess evolved from

initial efforts to develop a program for collecting

and reporting safety-related data

from operations in eastern Canada’s growing

offshore oil and gas industry, which

shares many of the same site characteristics

found in mining, such as remote locations,

harsh environments and minimal infrastructure,

and thus drew the attention of

mining companies as well. Prior to the start

of Focus FS’s relationship with DMC, Brown

said, the mining contractor had assessed a

number of software packages designed for

safety programs and found them lacking, as

they seemed to be designed mainly for filling

out forms to assure compliance. DMC

wanted to build a safety culture that would

be supported by information systems, not

vice versa. With ShiftProcess, said Brown,

they found an off-the-shelf software solution

offering the capability to custom-configure a system that could meet their immediate

and long-term safety goals.

“ShiftProcess can be configured to collect

data from specific workflows at specific

sites. It doesn’t force users to do things in a

certain way that doesn’t meet their needs,

but does allow easy standardization across

sites, so new operations can be up and running,

safety-wise, from day one,” explained

Brown. “We also designed it with typical

mining sites in mind, where training can be

difficult to schedule, particularly with operations

at which employees are on site for

a certain number of weeks and then home

for a few weeks. Data collection is straightforward

and users have access to ‘cheat

sheets’ that quickly provide guidance.”

The Focus FS/DMC joint effort is in line

with the overall trend in the industry as it

moves from 1990s paper-based reporting

and compliance systems to electronic systems

employing tablet-based data collection

and cloud technologies. EH&S managers

at several mining companies told E&MJ

that the immediacy of response provided by

electronic systems removes the basic flaw

of paper-based systems: workers get quick

responses to their safety concerns instead

of long delays; and managers spend less

time behind a desk, shuffling through paperwork.

Electronic systems’ capability for

providing immediate feedback helps companies

such as DMC that are working to

forge a less management-focused environment,

in favor of a safety culture based on

employee engagement and accountability.

This approach is gaining popularity,

particularly among companies that have

committed considerable time and money

to safety improvement but haven’t seen

results in proportion to the size of their

investment. During an interview with CBC

News during the Ontario Mining Health and

Safety conference held in Sudbury in April,

Alistair Ross, director of mining operations

for Vale Canada, said the concept of “zero

harm” adopted by most mining companies

may be achievable at any given moment —

but the key is “how long can you make that

moment last. We’ve found that zero harm

in work environments governed solely by

management systems is not achievable.

Bringing in a new style of leadership makes

the potential for zero harm much greater.

“We need to start looking at the availability

of each individual to become a leader

and contribute to the goal of zero harm,”

he said, noting that it takes a concerted

effort from all parties — corporate and

middle management, unions and individuals

— to recognize the opportunity and

demand workers step up and take responsibility

for safety concerns and policies.

“If I go to work and simply ‘hope’ to be

safe, that’s insufficient,” said Ross. “We

all need to ‘work’ to be safe. If we can get

better at understanding what it takes to

lead and follow this model, we can generate

longer periods of zero harm.”

Wearable Safety

The trend toward greater worker involvement

in safety and health has brought

with it a growing interest in wearable safety

tech. Radio frequency identification

(RFID) tags are increasingly being used

in both personnel and asset tracking and

safety applications in mining. Mojix, a

California-based RFID solutions developer,

pointed out that these tiny devices can

contribute to safety, security and efficiency

on many levels, with carefully placed RFID

readers able to track the movement of all

workers tagged with inexpensive, durable,

lightweight tags. The RFID system can be

linked with air quality sensors and blasting

schedules, meaning any worker in the

wrong place can be identified, contacted

and removed from danger. Safety equipment

can also be tagged, so in the event

of an accident, miners can be directed to

life-saving gas masks, refuge chambers

and the best location for escape or rescue.

SmartCap Tech recently announced a collaboration with Canada-based Newtrax Technologies to develop innovative

safety solutions utilizing SmartCap’s

SmartCap Tech recently announced a collaboration with Canada-based Newtrax Technologies to develop innovative

safety solutions utilizing SmartCap’s

LifeBand sensor band in underground mining applications. The LifeBand is

the latest in wearable tech offered by SmartCap Tech, following earlier

introduction of its SmartCap fatigue-sensing

and reporting system, shown here.

However, with the recent announcement

that a Midwestern U.S. technology

company had offered to fit its employees

with biochip hand implants to make it

easier to pay for lunch, access equipment

and move around controlled facilities, the

trend toward wearables in the workplace

has entered a new era. Although nothing

like that has been reported in the mining

industry, advances in wearable technology

are making these devices smart enough to allow a worker to assess his or her physical

and mental status based on real-time

brain-wave data, or to notify supervisors if

the worker is unable or unwilling to do so.

Australia-based SmartCap Tech recently

introduced the LifeBand, a follow-up product

to its SmartCap, which uses sensors in

the hatband of a purpose-built cap to conduct

EEG (electroencephalography) monitoring

of fatigue levels in the wearer. The

LifeBand, according to the company, uses

similar technology but can be fitted into any

type of headwear — hardhats, caps or beanies

— and will provide alertness readings via

Bluetooth to the user’s smartphone as well

as to a central reporting point, if desired.

Taking Over

At the other end of the technology spectrum,

larger, mine-wide systems, such as

those used for dispatch and fleet management,

are also becoming sophisticated

enough to take control of equipment out

of operators’ hands if the situation warrants,

based on sensor readings.

For example, in June, Hexagon AB announced

the launch of HxGN Mine VIS, a

vehicle intervention system that detects and

prevents collisions by automatically slowing

down or even stopping a haul truck if an imminent

collision is detected. The company

said Mine VIS is an additional layer of safety

on top of the Collision Avoidance System,

(CAS) helping to avoid incidents, injuries

and fatalities. Mine VIS manages traffic in

the pit and, by reacting when and if operators

do not, it ensures safety rules are followed.

CAS provides drivers of large vehicles

with 360° proximity detection at any speed

and in all conditions via cabin display units.

It is installed in more than 25,000 vehicles

in more than 60 mines worldwide.

According to Hexagon, Mine VIS can

take control of the machine in certain

defined situations if the operator does

not react appropriately to the initial CAS

warning. The system can act depending

on the situation, either by inhibiting

propulsion, activating the retarder or applying

the service brake. It can also be

used in conjunction with the company’s

fatigue-detection, alerting and reporting

solution, FatigueMonitor — using the

same sensors and user interface.

Mine VIS is being installed in Anglo

American Kumba Iron Ore’s Sishen mine

in South Africa, where government regulations

will compel surface mines to implement

such systems on heavy machine

equipment by June 2019.

In other applications, collision avoidance

systems can provide greater safety

for operators in less-obvious ways. For example,

Wenco International reported that

installation of its Fleet Awareness technology

at Nordgold’s Bissa-Bouly gold mine in

Burkina Faso is expected to help operators

cope with low-visibility conditions arising

from thick airborne dust clouds on site.

(For a leading fleet management system

provider’s view on emerging collision-

avoidance technologies and changing

regulatory requirements in the global

mining market, see “Technology Alone

Won’t Keep Workers Safe,” p. 51.)

Hands Off

In the underground sector, mine operators

are indicating greater interest in automating

various aspects of their loading and

haulage operations to not only improve

productivity but enhance worker safety and

asset preservation as well. E&MJ reported

in the July issue (See “Greens Creek

Moves to Automated Loading With Sandvik

System,” p. 75) that Hecla Mining Co.’s

Greens Creek operation is the first U.S.

underground mine to employ Sandvik’s

AutoMine machine-automation technology

to one of its loaders working in areas where

it extracts ore by bulk longhole methods,

and expects to add the capability to more

machines in the near future.

In Australia, Pybar, an underground

mining contractor, began testing a new

Haul Truck Guidance system from Perthbased

RCT at Aurelia Metals’ Hera mine

in New South Wales.

According to RCT, the gold and lead/

zinc project increased productivity and

reduced machine damage after equipping

two of Pybar’s Caterpillar AD45 ejectors

with the ControlMaster system that guides

the machines to loading and dump points,

only requiring operator intervention when

the machine is actually being loaded.

Pybar COO Brendon Rouse said the

system was significantly improving the

company’s ability to safely and efficiently

direct dump waste into a stope.

“The Haul Truck Guidance solution

has eliminated the need for operators to

steer the truck down the long drives, and

the need for developing truck turnaround

bays near the stope tip heads,” said

Rouse. “The system works in a similar

way to the current [RCT] Guidance system

fitted on several of Pybar’s production

loaders at numerous other sites.”

RCT’s product manager, Dave Holman,

said this solution evolved from the Control-

Master Loader Guidance solution. “It was

specifically designed for the haul truck application

after feedback from clients made

us aware of the issues they were experiencing

on site, which included costly damage

bills and erratic production results,” said

Holman. “RCT redesigned both the hardware

and software to suit the requirements

and a close collaboration with key mining

companies ensured our unique solution

was addressing all areas of concern.”

The steering, braking and speed of the

truck are automatically determined by the

minimum width of the drive and the lookahead

distance of the onboard laser units.

There is also an object detection feature

which further assists in tight areas.

“Automating the process simplifies

the task of driving a haul truck long distances

within tight space limitations to

deliver consistent cycle times while heavily

reducing machine damage simultaneously,”

said Holman.

Based on favorable results from the

system’s trial at Hera, Pybar reportedly is

evaluating its application at other sites.

As featured in Womp 2017 Vol 08 - www.womp-int.com