Figure 1—Typical installation of a nuclear densitometer for mineral processing applications.

Do Nuclear Instruments Always Need

to Be Used?

Restricting the use of radioactive densitometers as a way to improve safety

in mining operations

By Sidney A. A. Viana

Nuclear or radioactive densitometers (See Figure 1) are the most commonly used instruments to measure the density of ore slurries flowing in pipelines. Some advantages of nuclear densitometers are: non-intrusive and contactless measurement; easy external mounting on pipelines; no need for process operation stoppages during maintenance interventions; and robust construction. However, they also have drawbacks: the need for permanent safety care due to the risks of occupational accidents involving ionizing radiation and the need for field calibration using actual ore slurry from the production process, which rarely covers the full operating range, resulting in poorly representative calibrations.

Nuclear densitometers are a mature instrument technology with proven feasibility in several industrial applications. On the other hand, there are also several non-radioactive technologies for liquid density measurement. Certain industries such as chemical, petrochemical and pharmaceutical have been successful in using non-radioactive densitometers, which are not yet common in the mineral processing industry, due to a lack of knowledge about how to appropriately apply them, as well as due to the harsh industrial conditions of the mineral processing environment.

At Vale, a large global producer of iron ore, nickel and copper ore, radioactive densitometers have historically been used in the processing of ore slurries. However, an effort to replace such densitometers with non-radioactive alternatives was initiated in 2010 by the Southeastern Ferrous Department. Initially a survey on the existing radioactive densitometers was carried out, and feasibility studies to replace radioactive densitometers by non-radioactive alternatives were developed. The first replacements were done in 2011 using differential pressure densitometers [12]. In the following years, other models of non-radioactive densitometers such as vibrating fork [13,14], microwave [15] and ultrasonic [16] were tested for feasibility to operate with iron ore slurries. Not all of them were proven suitable, and some suffered from fast wear caused by slurry abrasion. In 2014, the Executive Ferrous Operations Department requested the elimination of radioactive densitometers from all Vale’s iron ore operations in Brazil, based on the cases of success attained by the Southeastern Ferrous Department.

Restricting the Use of Nuclear Densitometers

Safety has been a subject of major concern

for the mining industry. Removing radioactive

instruments from Vale’s Brazilian iron

ore operations would eliminate occupational

and health safety risks related to the

use of such equipment. This initiative was

implemented by means of two work fronts.

Discarding of radioactive sources — The goal of this work front was the definitive elimination of radioactive sources that were out of operation and stored with no intended future use. In Brazil, the National Commission for Nuclear Energy (Comissão Nacional de Energia Nuclear, CNEN) [5] is the government institution responsible for regulating and establishing legal norms for the use of radioactive materials and equipment in the Brazilian territory. CNEN is affiliated with the International Atomic Energy Agency (IAEA). According to the CNEN norms, any radioactive source not being used in operation should be stored at a specific and safe place (a storage bunker), until it should be reused or discarded to a radioactive rejects receiver institution. However, no maximum time limit is set for the storage of radioactive sources by the users. This favors the occurrence of deactivated radioactive sources being indefinitely stored, with no prospect for reuse, constituting a safety liability. In a similar way, radioactive sources installed in the field but without effective use (for example, in a deactivated industrial plant) could also be discarded if they have no prospect of further use. In short, the discarding of radioactive sources intends to reduce or even eliminate the safety liability related to the storage of unnecessary sources.

Replacement engineering development — The goal of this work front was the development of basic engineering for the application of non-radioactive densitometers to replace radioactive units used in mineral processing facilities, taking into account the specific characteristics of each application and non-radioactive alternative (measuring principle, measuring range, installation aspects, etc.). The starting point for this work front was to understand the replacement initiatives done earlier by the Southeastern Ferrous Department, to identify the successful applications of non-radioactive densitometers and their potential for replication in similar mineral processing facilities. In short, the replacement engineering was intended to establish suitable technical standards for the use of non-radioactive densitometers in place of radioactive ones.

The Work Strategy

For all Vale’s iron ore operations in Brazil,

an inventory of existing radioactive

sources was created, as well as sources

planned for acquisition in new projects.

The inventory would help engineers understand

how the equipment was distributed

among the sites, allow them to plan

the activities for discarding (work front

1) and to develop the replacement engineering

(work front 2). In the inventory,

the equipment was classified as: In Operation,

Stored, Acquired in Project and

Planned in Project (See Table 1). Figure 1

shows the numbers of radioactive sources

ascertained by the inventory.

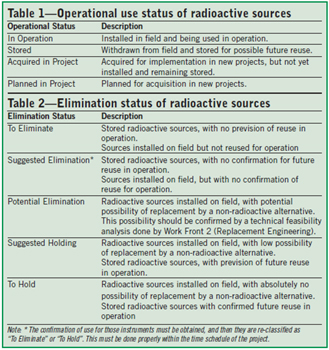

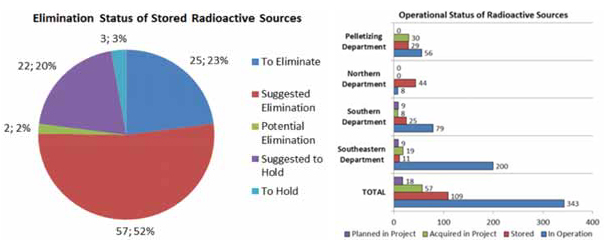

An assessment of the radioactive sources was made as far as the feasibility of elimination. Once all radioactive sources had been identified and recorded in the inventory, they were classified by their operational use and status, shown in Table 1. Those classified as In Operation were further confirmed as Necessary (without feasible replacement by a non-radioactive alternative) or Not Necessary (with feasible replacement by a non-radioactive alternative). Those classified as Not Necessary were then engineered for replacement. An additional classification regarding the elimination status of the radioactive sources is shown in Table 2, for the stored sources. Figure 2 shows the numbers of stored sources following this classification, for all operations departments. For example, 25 stored sources (23% of the total stored sources) were classified as needing to be eliminated.

In Brazil, activities for discarding radioactive sources must be done in compliance with the CNEN norms, specifically NN-5.01[8] and NN-3.01 [6]. Although the discarding activities can be carried out by the owner of the radioactive sources, it is strongly preferable to contract a disposal services company specialized in those activities. By this way, four service companies specializing in handling, packaging, transporting and delivering deactivated radioactive sources were consulted and evaluated, and one of them was selected for contraction.

To allow proper replacement of radioactive densitometers, specific technical documentation (e.g., specification sheets, datasheets, mechanical drawings and mounting arrangement drawings) was developed for the application of alternative non-radioactive densitometers, according to application criteria defined by VALE. An engineering services company was contracted to provide such documentation.

Work Front 1: Discarding of Radioactive Sources

Radioactive sources that have been laid

up and with no prospect of reuse are always

a safety liability. In Brazil, the discarding

of that equipment is subjected

to specific legal regulations, and must

be performed as a planned process of

handling, packing, transporting, and delivering

to a specific receiver branch of

CNEN. Among the CNEN branches qualified to receive deactivated radioactive

sources, three were considered: CDTN

(Centro de Desenvolvimento de Tecnologia

Nuclear, in Belo Horizonte, MG),

IPEN (Instituto de Pesquisas Energéticas

e Nucleares, in São Paulo, SP), and IEN

(Instituto de Engenharia Nuclear, in Rio

de Janeiro, RJ).

Work Front 2: Replacement Engineering

The object of this work front was to develop

the basic engineering for replacement

of radioactive densitometers by non-radioactive

alternatives. Some of those alternatives

were already in use at Vale and

other Brazilian mining companies, but not

all of them were operating efficiently. The

objective was to characterize more accurately

the cases of feasible application of

non-radioactive densitometers to minimize

the occurrence of failures due to the

inadequate implementation of potentially

feasible applications or the implementation

of actual infeasible applications.

Several non-radioactive densitometers

were evaluated for mineral processing:

• Coriolis [11]: Measures the density by

contact with a flowing liquid, using the

Coriolis principle, and are exclusively

applied to pipelines. They are currently

available for small- and medium-diameter

pipelines. For large-diameter pipelines,

they must be installed on a bypass

pipeline that samples the liquid from the

main pipeline. They have higher accuracy

and precision, but are not suitable

to operate with liquids containing solids

in suspension, due to clogging and/or

wear by abrasion. They are ineffective

for applications with ore slurries.

• Differential Pressure [12]: Measures the

density by contact with the liquid using

the hydrostatic pressure, which relates

the pressure of a liquid column to its

density. They have very good accuracy

and precision for applications in tanks

and reservoirs, if both pressure seals remain

submerged. They cannot be directly

applied to pipelines, since the liquid flow

invalidates the hydrostatic principle. For

such cases, the manufacturers usually offer

a “sampling vessel” for insertion of

the densitometer, to be connected to a

pipeline with pumped flow. However,

practical experiences have shown that

this solution is ineffective as the density

measurements are corrupted by pressure

variations in a pumped pipeline, and

the “sampling vessel” is often clogged by

settled solids from the slurry.

• Vibrating Fork [13,14]: Measures the

density of a liquid by sensing the resonance

frequency of a pair of vibrating

blades inserted into the liquid. They

have very high accuracy and precision,

and can be applied with success to

tanks and reservoirs, preferably with suitable mixing, for representative measurements.

They cannot be applied to

pipelines, due to quick wear by abrasion.

• Microwaves [15]: Measures the density

of a liquid from the time propagation

delay of microwaves transmitted through

a fixed path within the liquid. The higher

the fluid density, the shorter the propagation

delay. Those densitometers usually

have a tubular shape, for pipeline installation.

They provide good accuracy

and precision, but are unsuitable for

measuring abrasive liquids due to the

quick wear of their internal coating in

contact with the liquid. In a test conducted

by Vale in 2014 with a polyurethane-

coated microwave densitometer,

the equipment lasted only 20 days, due

to internal wear.

• Ultrasound [16]: Measures the density

of a fluid from the time propagation

delay of ultrasound waves transmitted

through a fixed path within the liquid.

The higher the liquid density, the shorter

the propagation delay. Like microwave

densitometers, they are usually

constructed in a tubular shape for pipeline

applications, and suffer heavily

from abrasion.

• Tomographic [17]: Measures the density

of a liquid by tomographic principle,

by sensing the liquid resistivity of the

passage of an electric current through

the liquid. The higher the liquid density,

the greater the resistivity. Those densitometers

consist of a set of electrodes arranged

on a tubular or rod-shaped body.

For applications with abrasive slurries

flowing in pipelines, there are tubular

models with ceramic inner coating,

which is more robust to wear than other

coating types like polyurethane. The rodshaped

models are suitable for density

measurement in tanks and reservoirs.

It is a promising new technology, but still

with few user references about its practical

performance.

• Gravimetric [18]: Measures the density

of a fluid by the gravimetric principle.

A straight tube with known length and

diameter is supported by one or more

load cells, which sense the mass of the

liquid inside the tube. The liquid density

is determined by dividing the sensed

mass to the known internal volume of

the tube. It has reasonable accuracy

and precision, if the pipeline operates

fully filled by the liquid. It cannot be

applied to vertical pipelines. Excessive

mechanical vibrations on the measuring

tube will affect the load cells and may

corrupt the density measurement.

In mineral processing plants, ore slurries

pass through pumping pipelines and

storage tanks, in addition to the mineral

processing equipment. Tanks and pipelines

have more appropriate conditions

for the installation of density measuring

instruments, depending on the measurement

technology used. Two key aspects to

consider in the application are:

• Abrasion — Flowing ore slurries are

strongly abrasive because of the movement

of ore particles relative to object

parts in contact with the slurry. Nonradioactive

densitometers usually perform

measurements by contact with

the liquid, and are therefore subjected

to some degree of abrasion, which may

significantly reduce their lifespan. Any

application of non-radioactive densitometers

to ore slurries must be designed

to minimize the effects of abrasion on

the instrument.

• Typical Installation Design — Each

type of non-radioactive densitometer

has a specific physical construction,

which determines the way it can be installed.

For example, tubular-shaped

microwave densitometers can only be

installed in pipelines. On the other hand,

rod-shaped differential pressure densitometers

are more suitable for installation

in tanks. Therefore, the development of

“typical installation standards” for each

application of non-radioactive densitometer,

considering the specific application

needs regarding the instrument

and the process, allows the standardization

of the applications and increases

the chances of success.

Results

The assessments for elimination of stored

radioactive sources allowed the discarding

of 86 sources in 2014. According to

Figure 1, the original total number of radioactive

sources (In Operation + Stored

+ Acquired in Project) was 509 sources.

The 86 sources discarded represents a

reduction of 17% in the total number of

existing sources. For radioactive sources

classified as Planned in Project, recommendations

were made to change the engineering

designs to use non-radioactive

alternatives whenever possible.

The replacement engineering work front identified 71 feasible applications of radioactive densitometers that could be changed to use non-radioactive alternatives. The engineering project documentation for those applications were developed and delivered to the representatives of each department. However, the actual replacement of those densitometers depends on the implementation of the respective projects, through the acquisition and installation of the non-radioactive alternatives.

The results of discarded radioactive sources were considered an important milestone for the reduction of safety liabilities in the iron ore operations. Given the geographic dispersion of the site operations, the involvement of management levels of each site was fundamental to the success of this project. Systematic planning and follow-up was crucial to keep everyone informed of advances, problems and difficulties throughout the project.

The discarding of more radioactive sources in the following years depends mainly on the implementation of the replacement engineering projects, along with the maturation of the knowledge about the application of non-radioactive densitometers in mineral processing facilities. For applications with impracticable replacements, the use of radioactive densitometers should be kept.

An important benefit of this project was the definition of objective criteria for the use of non-radioactive densitometers as an alternative to radioactive ones. The lack of such criteria favors the indiscriminate use of non-radioactive alternatives, resulting in incorrect applications.

Although the nuclear instrument technology has its advantages, non-nuclear alternatives with similar measurement performance and robustness should be preferred. The goal is to attain a better balance between instrument accuracy and safety liability regarding the use of nuclear instruments.

Sidney A.A. Viana is a specialist automation engineer at Vale’s Ferrous Automation Engineering Department. He can be reached at sidney.viana@vale.com.

Acknowledgment

The success of this project was possible

due to the effective engagement and

teamwork of many people. The author

acknowledges the partnership of his local

department colleagues, Herbert Mascarenhas, Gustavo Martins, Diogo Pires, and

Gilberto Resende, for their contributions

to the planning and management of this

project. Thiago Rezende (Southeastern

Ferrous Department), Julio Faria and Solange

Nunes (Pelletizing Department), and

Michel Martins (Southern Ferrous Department)

are specially acknowledged for sharing

information about the equipment from

their departments, and for supervising the

execution of project activities on their site

operations. Finally, the author thanks Luciano

de Biasi, Kleber Saldanha, and Kênio

Figueiredo (former engineering managers)

for their managerial engagement and

administrative support.

References

1. Wills, B.A. & Napier-Munn, T.J. “Will’s

Mineral Processing Technology,” Seventh

edition. Butterworth-Heinemann. 2006.

2. Richardson, J.M. & Morrison, R.D.

(Fuerstenau, M.C. & Han, K.N., editors).

“Principles of Mineral Processing.” SME

Society for Mining, Metallurgy and Exploration.

Littleton, CO, USA. 2003.

3. Rezende, T.M. (VALE) “Projeto Eliminação

de Fontes Radioativas” (corporate

presentation). 2013.

4. Viana, S.A.A. (VALE). “Inventário de

Fontes Radioativas da Diretoria Operacional

de Ferrosos” (spreadsheet

file). 2014.

5. Comissão Nacional de Energia Nuclear

(CNEN). www.cnen.gov.br.

6. Comissão Nacional de Energia Nuclear

(CNEN). “Norm NN-3.01: Diretrizes

Básicas de Proteção Radiológica.”

Rio de Janeiro, RJ. March 2014.

7. Comissão Nacional de Energia Nuclear

(CNEN). “Norm NE-3.02: Serviços

de Radioproteção.” Rio de Janeiro,

RJ. August 1988.

8. Comissão Nacional de Energia Nuclear

(CNEN). “Norm NN-5.01: Transporte

de Materiais Radioativos.” Rio

de Janeiro, RJ. August 1988.

9. Comissão Nacional de Energia Nuclear

(CNEN). “Norm NE-6.05 Gerência

de Rejeitos Radioativos de Baixo e

Médio Níveis de Radiação.” Rio de Ja

neiro, RJ. April 2014.

10. OHMART-VEGA, “Radiation-Based

Density Measurement with DSG,”

OHMART-VEGA, Cincinnati, OH, USA.

11. Endress+Hauser, “Promass 80F, 80M,

83F, 83M Coriolis Mass Flow Meter

– Technical Information (TI053D/06/

en/06.08),” Endress+Hauser, Reinach,

Switzerland, 2008.

12. SMAR, “Transmissor de Densidade

DT400: Manual de Instruções, Operação

e Manutenção,” SMAR, Sertãozinho,

SP, Brasil, 2014.

13. Endress+Hauser, “Liquiphant M FT

L50(H), FTL51(H) Technical Information

(TI328F/00/en/14.12),” Endress+

Hauser, Reinach, Switzerland, 2012.

14. ROSEMOUNT. “MicroMotion 7826/

7828 Series Density and Concentration

Meters” (product datasheet PS-

001056, rev. A). February 2008.

15. Kajaani Process Measurements, “KC7

Microwave Density Transmitter Product

Sheet,” Kajaani Process Measurements,

Kajaani, Finland.

16. Rhosonics. “9690 Series Density Ana

lyzer” (brochure).

17. ITS Industrial Tomography Systems (online).

www.itoms.com

18. MS Instrumentos. “Gravimax: Sistema

de Medição e Controle de Densidade e

Fluxo de Massa” (brochure).

19. VALE. “Projeto S2110-01. Eliminação

de Fontes Radioativas – Locação

de Instrumentos: 1000PI-J-

12218 r0.” Agosto 2014.