RMS-Ross’s variable-pitch sluice can be adjusted to tailor the slope to the

individual site conditions.

Going With Gravity

A roundup of current technologies that use the force of gravity for heavy mineral recovery

By Simon Walker, European Editor

Far predating many of today’s mainstream mineral processing technologies, gravity separation was unquestionably the earliest method of mineral recovery devised. An understanding of the mechanisms behind the formation of alluvial gold and tin deposits led to the invention of sluicing and panning—techniques that still provide small-scale miners worldwide with their livelihoods, and which have since been developed as mainstream recovery methods for heavy minerals.

The principles behind the water jig were well-understood in medieval times; dry jigging is a more recent development. With increasing interest in recycling, the use of tables has extended from primary mineral production to recovering the valuable components in scrap, while spirals are a key component for upgrading commodities such as mineral sands, metallurgical coal and iron ore.

And, of course, the relatively recent development of various types of bowl concentrators has improved on the concepts behind simple panning by enhancing the gravity effect available through the use of centrifugal force.

20 Years of Tables

Having inherited the rights to the technologies

from the original equipment manufacturers,

U.K.-based Holman-Wilfley has

been producing Holman and Wilfley shaking

tables for nearly 20 years. The company’s

managing director, Chris Bailey, told

E&MJ that its Holman option provides a

unique design layout and separation capability,

and provides higher concentration

and recovery of ultra-fine minerals

compared to standard Wilfley designs.

New construction materials and engineering techniques, incorporating knowledge from the automotive industry, have contributed to the machine advancements, Bailey added, although the known principles of hindered settling have remained the focus in an ever more challenging minerals market. “These machines are associated closely with other gravity devices as part of flowsheet development, although no recently developed devices are capable of matching the enrichment ratios possible with gravity tables,” he said.

Applications include titanium-bearing heavy mineral sands, tantalum, tin, tungsten, chromite and gold, with the company currently closely associated with tin and tungsten projects in Spain, Australia and South America. Holman-Wilfley also recently supplied 42 of its Holman 8000DD table decks to titanium producer Tronox for its Namakwa Sands Wet Gravity Extension Project, some 350 kilometers (km) north of Cape Town on South Africa’s west coast. The units recover zircon from rutile and ilmenite-separation tailings, with the initial concentration using spirals and final concentration on the Holman tables.

Extending Jig Capabilities

According to marketing manager, Luciano

Devoto, Gekko Systems developed its Inline

Pressure Jig (IPJ) over 15 years ago.

While it was originally used to pull free

gold from milling circuits and within alluvial

gold circuits, over the past few years,

the equipment has been modified to treat

a wide range of heavy minerals, utilizing

different jigging parameters, screen configurations and ragging densities. The unit can now be completely automated

and integrated into mill-control systems,

making it a more robust option for recovering

heavy minerals, he said.

Advantages claimed for the IPJ include high mineral recovery and unit throughput, better security since the equipment is fully enclosed and pressurized, local control of the jig parameters, and low installation costs, with improved plant capacity and lower operating costs being delivered by rejecting low-value material ahead of further processing. Gekko also stated that the IPJ uses 20% less power and consumes 10% of the water, compared to traditional jigs.

IPJs are available in several sizes, with feeds up to 250 metric tons per hour (mt/h) for larger operations, as well as having a small operational footprint and being easy to ship. Flexible jig components and adjustable operation modes allow the IPJ to be set to specific ores and current applications, Gekko noted.

For the coal industry, the company now offers its IPJ-Coal Separator (IPJ-CS) used to remove heavy gangue and ash from lightweight coal material, with less impact on the environment compared to conventional coal plants. Thoroughly tested on a range of Australian coals, the IPJCS helps to increase saleable coal quality and quantity as well as improving waste recoveries, reducing energy and transport costs, and streamlining coal processing.

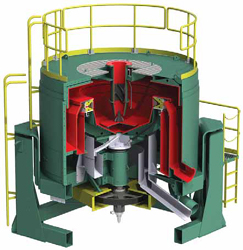

Enhancing Gravity

With capacities ranging from laboratory

scale to 1,000 mt/h of solids, the

Knelson batch concentrator from FLSmidth

combines centrifugally enhanced

gravitational forces with a fluidized bed

process to recover precious metals. Project

engineer Maher Sabouneh told E&MJ

that these units can operate on feed densities

of up to 75% solids while achieving

best-in-class metallurgical performance.

Knelson batch concentrators can be installed in grinding and regrind circuits, treating either a portion or the entire circulationg load. This leads to improved overall gold recovery, higher and faster gold payment, reduced stripping and downstream reagent costs, and improved security, he added. They can also be installed in flotation streams in open circuit to remove gold values.

Used for preconcentration ahead of leaching, Knelson continuous concentrators are installed in the leach feed to recover slow-leaching species, allowing aggressive post-treatment such as fine grinding and intensive leaching to be employed. Alternatively, both batch and continuous types can be used for tailings treatment, with batch concentrators better suited for scavenging of free precious metals while continuous concentrators are used to recover slow-floating or slow-leaching sulphides.

Redesigning Table Options

John Christophersen, international sales

manager for Deister Concentrator, told

E&MJ the company specializes in manufacturing

shaking tables for gravity concentration.

Recent advances have included

the development of enhanced riffling

systems for sand and slime mineral separation,

and the introduction of molded

HDPE launder systems for Deister’s Triple-

Deck 999, Double-Deck 99 and Single-

Deck 6 shaking tables.

With the enhanced riffling systems, particular emphasis has been placed on cleaner applications with the introduction of “take-off” riffles for handling greater quantities of concentrate without sacrificing capacity. The molded HDPE launders provide the operator with better vision to observe the separation on the middle and bottom decks of a triple-deck table, while they are easier to adjust because of their lighter weight when compared to steel launders. In addition, the slick interior surface reduces material backups and the use of “push water.”

The company claims that its modular Triple-Deck 999 suspended tables offer a number of advantages over conventional designs, and they have been shown to outperform virtually any other concentrating tables on the market today. With a rhomboidal shape, they are easy to operate with low maintenance requirements, Deister stated, and since they are fully suspended, they require less floor space than floor-mounted units. This provides an advantage for the operator in remote locations, and also where a concentrator has to be moved from site to site.

Christophersen said the company is now completing designs for four-deck, five-deck and six-deck suspended tables. As mining companies consider gravity concentration of finer minerals, floor space becomes a consideration, he pointed out, with these new designs allowing for increased capacity per unit of floor space. The largest Deister table installation is currently located in southeast Asia, where more than 100 Triple-Deck 999 tables are used to concentrate tungsten ore.

Spirals for Minerals and Coal

With its headquarters in Queensland, Australia,

Mineral Technologies is one of the

world’s leading suppliers of spirals for mineral

processing applications. The company’s

business development manager, Dale

Henderson, explained that over the past

15 years, the company’s technology development

programs have resulted in the

introduction of several new spiral models.

For example, the FM1 fine mineral spiral was developed specifically to process fine mineral sand ore in the range of 30-150 µm (100–400 mesh), but has since been applied to a number of other fine mineral separation applications. In this size range, it is also an alternative to flotation where a specific gravity difference exists between the valuable and gangue minerals. Available in 6.5- and 8.5-turn configurations, with single, twin or triple starts, each FM1 can handle 600 kilograms (kg) to 2 mt/h of solids at a 30%-55% solids pulp density.

The MG12 two-stage rougher/scavenging spiral has 12 turns and features three auxiliary concentrate (slide) splitters spaced at three-turn intervals. A pair of ganged, pivoting splitters at the bottom provide for a fourth concentrate cut and facilitate the middling/tailing split. The model is available as a single-, twin- or triple-start assembly.

The company said the high separation efficiency afforded by the 12 turns of the MG12 means that, while its trough diameter is no greater than that of an MG4 or MG6.3 spiral, its performance is more resilient to increased loading. Hence it has a higher feed capacity. The high concentrate grades and recoveries achievable on an MG12, in a single pass, lead to concentrator plants that are both greatly simplified and capable of higher overall metallurgical performance, it added.

Other recent developments have included the HC33 spiral, used to treat streams containing mostly high specific gravity (SG) material, and which can be operated with the use of additional wash water if required. Meanwhile, the four- and eight-turn LC3 spiral for coal cleaning consistently achieves an SG cut-point down to 1.45 and produces Ep values of 0.1, lower than any other spiral currently in the market, Mineral Technologies claimed. These spirals enable coal plant operators to generate cleaner (low ash) coal or a higher yield of coal with the same ash.

Sepro Sells to Russia

Canadian company Sepro Mineral Systems

offers three versions of its Falcon gravity

concentrator: the C, SB and UF models.

Designed for continuous duty, with unit

capacities of up to 100 mt/h, Falcon C

can produce mass yields as high as 40%,

its primary objective being to maximize

mineral recovery and reduce tonnage to

downstream processes. It can also be used

for scavenging or preconcentrating, since

no water is added during processing.

The larger Falcon SB is a semibatch machine, with continuous feed and periodic rinse cycles. Generating 50 to 200 G, capacities are up to 400 mt/h, with a typical application being the recovery of liberated precious metals within a grinding circuit or from placer deposits.

Meanwhile, the high gravitational fields (up to 600 G) generated by the Falcon UF allows the recovery of ultra-fine particles as small as 3 µm. A common application is in scavenging ultra-fine particles from a plant reject slimes stream. All of the Falcon models have a small footprint, and feature fully automated, one-touch operation that provides the least amount of offline time and highest possible concentrate security, Sepro said.

Earlier this year, the company reported the sale of further SB750B gravity concentrators to Polyus Gold’s Natalka project in the far east of Russia. Polyus’s operating subsidiary, Rudnik Imeni Matrosova, commissioned its gravity-only gold-recovery plant in 2015, with the first stage achieving around 65% recovery from ore grading about 2 g/mt. The additional Falcon units are expected to increase overall recovery to 72%-75%.

Outotec’s Spirals

The HC8000 spiral from Outotec is a

seven-turn, wear-resistant polyurethane/

fiberglass unit. Each spiral start has up to

six super concentrate collection splitters

designed for easy adjustment and repeatable

positioning. The product discharge

box splitter has a similar design. All splitter

handle indicators are readily visible

so that the operators can see and adjust

large numbers of handles accurately and

quickly. Spirals are supplied complete

with detachable feed and product discharge

boxes, and the product box will

collect product, middlings and tails from

each spiral start simultaneously.

The company’s five- or seven-turn H9000 series spirals are available as either washwater or washwater-less designs. According to Outotec, the washwater model (H9000W) is suited for the treatment of high-grade feeds, like iron ore, which might benefit from supplementary washwater to remove gangue minerals. Each spiral turn on the H9000W is equipped with washwater cups, with a washwater distributor proportionately distributing water to each cup down the length of the column, regardless of changes in the flow rate. Both spiral models are available in single-, double- or triple-start configurations.

Derocking to Increase

Reserves

Company President Scott Plummer told

E&MJ that RMS-Ross Corp.’s Derocker

system allows rapid easy processing and

recovery of the values concentrated in

bouldered alluvials. The units can handle

boulders up to 1.2 m (4 ft) in diameter,

bringing previously unmineable ground

into reserves.

The company has recently changed to using high-impact flat-pan spray nozzles and high-pressure sprays, which has given more effective scrubbing of values from coarse boulder and cobble while using much less process water. The underflow can then feed downstream secondary recovery circuits, such as advanced jig plants and centrifugal concentrators. The Derockers are equipped with remote control for safer operation, with full speed and stroke adjustability to suit the ore.

Plummer also explained that RMSRoss’s modular circular jig plants can be shipped, set up and taken down easily, having high commonality of parts. They have been redesigned to better handle feed ores with unusually high concentrations of heavy mineral, he added. All slurry paths can be autoclaved with rubber for long life. The modular design allows for scaling of the operation, while the potential use of a range of different specific gravity jig ragging or jig bed media can also allow for more effective separation of the target minerals or metals. The company’s new secondary jig design allows for the same travel distance of feed material as on the larger 9 ft jig, but in a compact arrangement, he said.

Other Options

E&MJ asked each of the companies for

their views on whether they envisage gravity

separation becoming used more widely

within mineral processing, perhaps in a

preconcentrating role. “This only makes

sense in so many applications,” said RMSRoss’s

Plummer. “The gravity separation

process economics are clear. Any preconcentration

of heavy minerals that can be

completed with gravity separation before

getting into secondary and tertiary concentration

and separations of product streams

should certainly be considered first in any

potentially applicable ore situation. This

can considerably decrease downstream

processing costs. There has been quite a

resurgence due to its simplicity, effectiveness

and low environmental impact.”

Dev Saini, spokesman for Sepro, agreed. “Absolutely,” he said. “Sepro is well aware of the need to reduce the capital costs associated with new projects as well as reduce industry-wide energy consumption. We believe that effective preconcentration and early waste elimination is going to play a key role in mineral processing plants of the future, and we believe that gravity concentration is perfectly positioned to play a role in these developments, specifically for particles that are too fine to be economically sorted through sensor-based techniques.”

For Gekko, Devoto said, “We believe that preconcentration will play a very important role in the future of mineral processing. The ability to recover a high mass yield using a continuous gravity concentrator is very appealing, as it offers a very low-cost solution to upgrade what would normally be considered uneconomic ores.”

And with Mineral Technologies’ perspective, Henderson added, “Our spiral separators have been applied as preconcentrating devices for many years. We believe these applications will grow.”

And for the future?

“Leaving aside new applications in terms

of other minerals, are there any technology

improvements that you can foresee

that could offer better separation than

can currently be achieved?” asked E&MJ.

From Holman-Wilfley, Bailey suggested the continued development of operational control and instrumentation. Devoto looked at manufacturing aspects. “Most of our work to optimize the ‘separation’ is in adjusting the internal ragging density used within the IPJ,” he said. “Gekko has its own injection molding machine enabling us to produce any ragging size at any SG. This really helps in fine tuning the separation of the mineral no matter what size or density split we are trying to achieve.

“The other thing is to look closely at the liberation characteristics of the ore,” he added. “Often a slightly finer crush can make a big difference in the separation efficiency of the unit.”

Henderson of Mineral Technologies concentrated on design matters. “Our current research and development is focusing on a significant change to the design of spiral separators,” he said. “It is too early to detail these developments, but suffice it to say that the spirals we supply into gravity concentration plants in five years’ time will look nothing like the spirals that we see today.”

For Plummer at RMS-Ross, a key development will be the use of gravity separation to widen operators’ product options. “One of the exciting advances that we have been seeing with our RMS modular jig plant is in tailoring the concentrate multistage separation and analysis lab work. Where previously customers had one or two target minerals or metals, since these plants concentrate the vast majority of all the heavy mineral, rather than rejecting all but the heaviest, we have been able to work with specialized mineralogical labs in order to create up to seven high-grade saleable products from the one concentrate stream and actually multiply what they had projected as their revenue stream, as well as greatly reduce the residual concentrate tailings.”

And for Dev Saini at Sepro, the future is already here. “Sepro is about to commercially release a centrifugal concentrator for gold recovery that does not use any additional fluidization water,” he told E&MJ. “We believe this is a significant technology breakthrough that not only improves gold recovery, but also reduces the fresh water demand in the milling circuit—something that is crucial not only for managing the water balance in milling circuits, but also for reducing pumping requirements and eventually reducing the amount of water pushed to tailings impoundments.”

Clearly, interesting times remain ahead for gravity separation in all its forms. 1990s.