From the left: Kevin Crutchfield, Contura Energy; Denise Johnson, Caterpillar; Nevada Gov. Brian

From the left: Kevin Crutchfield, Contura Energy; Denise Johnson, Caterpillar; Nevada Gov. Brian

Sandoval; Phillips

S. Baker, Hecla Mining Co.; Douglas Hardman, J.H. Fletcher & Co.; and Hal Quinn,

NMA, opened the show with a

ribbon-cutting ceremony. An estimated 44,000 people attended the

three-day event.

The U.S. National Mining Association’s

(NMA) MINExpo INTERNATIONAL 2016

trade show and convention, held September

26–28 at the Las Vegas Convention

Center, drew more than 1,900 exhibitors

and covered more than 840,000 ft2 to

showcase the latest mining equipment

and technology. The quadrennial event

attracted more than 44,000 attendees

from more than 130 countries.

Nevada Gov. Brian Sandoval; Denise

Johnson, MINExpo chair and group president

for resource industries at Caterpillar;

Kevin Crutchfield, CEO of Contura Energy;

Phillips S. Baker, president and CEO

of Hecla Mining Co., Douglas Hardman,

vice chairman, J.H. Fletcher & Co.; and

Hal Quinn, president and CEO of NMA,

opened the show with a ribbon-cutting

ceremony. “The 44,000 people participating

in MINExpo this week are a testament

to the significant role that mining

plays in the U.S. and around the world,”

Quinn said. He explained that, in the

U.S., mines accounted for more than

565,000 direct jobs, which provided

about $100 billion in payroll in 2015.

Thousands of people attended the

opening session. The theme was the

Global Outlook for Mining and Fox News

analyst Nina Easton moderated a panel

of executives, which included a U.S.

copper miner, Red Conger with Freeport

McMoRan; a U.S. gold miner, Gary Goldberg

with Newmont Mining Corp.; a U.S.

silver miner, Baker from Hecla; a U.S.

coal operator, Crutchfield from Contura

Energy; and a U.S. mining equipment

manufacturer, Ted Doheny with Joy Global.

The discussion touched on everything

from technology to industry disruption

to the difficulties with the public policy

environment for mining. As one would expect,

the coal operator, who had recently

emerged from bankruptcy, and the equipment

maker were the least optimistic.

Riding a wave of higher prices, the precious

metals miners were cautiously optimistic.

In general, they offered a realistic

outlook for commodity markets for 2017

and beyond, which was positive.

At two awards luncheons, the NMA

also recognized 26 mining operations for

exemplary and innovative service in mine

safety, reclamation and environmental

performance, and community outreach.

In a year when so many wondered how

challenging industry trends would impact

the event, all of the exhibitors E&MJ

spoke to said they were pleasantly surprised

with the turnout.

What follows are brief highlights collected

from E&MJ’s editors as they covered

the show floor. Over the course of

the next six months, these topics will be

discussed in more detail.

Aramine Debuts Battery

Powered Miniloader

At the French pavilion in the South Hall,

Aramine unveiled the L120B miniLoader

for narrow vein applications. The 24-

kW, battery-powered machine is capable

of operating in drifts as narrow as 2.3

m2. Equipped with a 0.5-m3 bucket, the

0.93-m-wide machine has a 1.1-metric-

ton (mt) payload capacity.

Atlas Copco Focuses on Automation

Under the slogan “The Future of Mining

is Now,” the Atlas Copco stand showcased

the company’s latest equipment,

geared toward increasing efficiency and

lowering the total cost of operation. The

recent advances made by Atlas Copco in

automation are considerable and some

have been described as game-changers

for the industry. Among those that were

demonstrated included next-generation

automation for surface drilling with innovations

such as Automatic Rod Changing,

smart Auto Navigation, and the next generation

of Auto Drill for rotary Pit Viper

drills that uses bit information to make

changes to drilling performance in real

time. For underground miners, the company

discussed the recent improvements

to the Scooptram automation system with

multimachine capabilities that gives full

control of loading operations. Through the

mine data network, up to 35 Scooptram

loaders can be connected and controlled

from one or several control rooms.

Atlas Copco’s Minetruck MT65 is an articulated underground truck with a 65-mt load capacity.

Atlas Copco’s Minetruck MT65 is an articulated underground truck with a 65-mt load capacity.

The company also highlighted Certiq,

a telematics system that gathers, com-

pares and communicates vital machine

performance data together with other

tools to improve workflow and monitor

and manage fleets.

The two newest products in the Pit

Viper family of rotary drill rigs were unveiled.

The first was the Pit Viper 231—

the latest rig for single pass drilling in

the 6- to 9-7/8-in. (152- to 250-mm)

hole range; followed by the updated, fully

autonomous PV-275, which offers largehole

drillers greater value and lower operating

costs, according to Atlas Copco.

Atlas Copco introduced the underground

Minetruck MT65, the Boomer

S2 underground drill rig and the Easer

raiseboring machine. With a 65-mt capacity

and an efficient powertrain, the

MT65 promises to dramatically increase

productivity. The truck is designed to

maximize uptime thanks to its service-

friendly design and easy access to

daily checkpoints. Comprehensive safety

features, a comfortable work environment

and a proven control system that

enables smart solutions, all contribute to

increased production and improved underground

haulage.

According to Atlas Copco, no other rig

in its class can match the productivity of

the new Boomer S2 drill rig at such low

operational cost. The rig is said to work

harder and longer with strengthened components

and increased parts protection

resulting in minimal internal wear, faster

drilling and overall durability.

The rig’s newly introduced COP MD20

rock drill is said to be 10% faster in

blast and bolt hole drilling than comparable

rock drills on the market, while at

the same time Atlas Copco’s dampening

technology improves drill steel economy

and increases drill uptime.

Easer, the Atlas Copco mobile raiseborer,

operates in the same way as a traditional

raiseborer, but can be easily moved

to wherever it is needed in the mine. In

addition to making the work safer and

more efficient, all moving and lifting is

done with a remote control crane. The rig

is wheel mounted, making it exceptionally

easy to move, and for fast and easy setup,

no concrete platform or site preparation

is necessary.

When it comes to rock drilling tools, Atlas

Copco Secoroc introduced new products

as well as updates for existing solutions.

These included bits for rotary and Downthe-

Hole (DTH) drilling, the new Azure and

Discovore exploration bits, and the Powerbit

top-hammer range for surface drilling.

A Powerbit version for underground drilling

is also slated for launch soon.

Boart Longyear Makes it ‘Hands Free’

Boart Longyear introduced the LF160

drill rig and FREEDOMLoader, which the

company said features totally hands-free

rod handling. The combined rig and loader

require no intervention from the drillers

assistant to trip in and align the rods or

connect to the top drive head, thus offering

greater freedom to drill by reducing

the risk of hand and back injuries while

handling rods. The FREEDOMLoader features

a remote control panel, “which allows

drillers to move to and work from a

safer location and away from the risks of

moving rods,” Boart Longyear said. It can

also cycle 6-m rods in the same amount

of time as a manual cycle, meaning enhanced

safety is achieved without compromising

productivity.

The LF160 drill rig and FREEDOMLoader from

The LF160 drill rig and FREEDOMLoader from

Boart

Longyear features totally hands-free rod handling.

The company reported the combination

also features a forward-tilting

head design, a clamping device that

maintains constant pressure at any hole

depth, a wireline winch located in the

front of the mast and inside the rotation

barrier, depth capacity of up to 1,800 m

of NQ, the choice of a Tier 3 or 4 final

engine, and either a crawler or truckmount

configuration.

Caterpillar: New Trucks and Technologies

At a pre-show briefing held for the trade

press, Caterpillar mining executives emphasized

that, despite the company’s recently

announced pullout from the underground

room-and-pillar and surface track

drill equipment sectors, it remains firmly

committed to serving the global mining

industry. To highlight this commitment,

it presented a variety of new and upgraded

surface-mining products ranging from

the 794AC high-capacity rigid hauler to a

latch-free dipper system for large mining

shovels. Also offered for the underground

market was the R1700K LHD, the Rock

Straight “longwall for hard rock” mechanized

cutting and transport system, and

the 22-mt-payload AD22 underground

truck.

The new 794 AC hauler, according to

Cat, is designed and built to minimize

total costs. As a true 291-mt (320-ton)

truck, it accommodates additional weight

allowances for options and body liners—

so the truck can be fitted for improved

durability without significant negative effects

on production. Mechanical availability

of the 794 AC during extensive mine-

site testing has averaged 90% or better

from the introduction and has continued

to improve. The drive system is designed

to power the larger Cat 795F AC, which

has demonstrated drive train component

life of more than 30,000 hours.

Cat said its LatchFree Dipper System

is the first successful solution to the most

common cause of rope shovel downtime.

The system replaces the standard maintenance-

intensive latch assembly with a

durable steel link assembly mounted to

the dipper back. The key to the design is

the geometry of the locking mechanism.

The unique arrangement makes it possible

to locate the components away from

the abrasive flow of material. The system

is available for Cat’s electric rope shovels

with dipper capacities as large as 49 m3

(65 yd3).

Cat’s new 794AC shares AC drive system characteristics with the

Cat’s new 794AC shares AC drive system characteristics with the

larger 795AC.

The R1700K delivers a payload of 15

mt, 20% more than the previous model

and supporting efficient three-pass loading

of the 45-mt-capacity Cat AD45B Underground

Truck. After rigorous field testing

is completed in 2017, the R1700K

will be commercially launched in 2018.

It will be powered by a C13 ACERT diesel,

available in EPA Tier 4 Final/EU Stage IV

and in Tier 3/Stage III emissions compliance

configurations.

MineStar Detect object detection

systems are now offered for additional

Cat machines and virtually all brands of

mobile surface mining equipment. Previously

unsupported Cat machines as well

as other brands of machines can now be

equipped with the cameras, radars and

in-cab displays that deliver increased site

awareness to mobile equipment operators.

Object detection kits are available

with one to four cameras and up to eight

radars.

Also offered is a new Proximity Awareness

collision avoidance system for surface

vehicles. Part of the MineStar Detect

capability set, the system uses peer-topeer

communications and is claimed to

provide fast, reliable communications

between vehicles, presenting collision

avoidance information to operators without

the need for a robust radio network

covering the site. The onboard hardware

can be fitted to light vehicles and to any

brand of surface mining equipment.

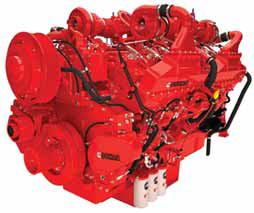

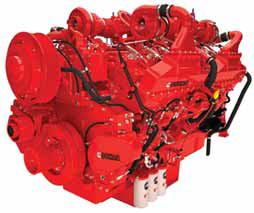

Cummins Ignites TCO Initiatives

Cummins introduced several initiatives

aimed at reducing engine TCO (total cost

of ownership) and streamlining engine

health monitoring and diagnosis. Among

them is its Data Enabled Mining Solution—

a new prognostic capability that

allows Cummins to monitor engines and

deliver accurate, real-time operating information,

enabling a quicker and more

focused response to potential issues.

Customized maintenance and operations

solutions can reduce costs by providing

operational data visibility such as driver

behavior and idle mapping.

Cummins Fuel Saver upgrades are currently available

on the

Cummins Fuel Saver upgrades are currently available

on the

QSK60 (shown here) and QSK50 engines.

The Data Enabled Mining Solution

operates over cellular networks, and in

the near future, satellite communications

systems. The system is able to stream

real-time, high-frequency data, which,

when coupled with support from the expertise

in the company’s solutions center,

allows monitoring of an entire fleet, 24/7.

Cummins’ fuel consumption reduction

initiative, called Fuel Saver, is currently

available for QSK50 and QSK60

engines, with plans to extend it to other

high-horsepower engines. It offers a number

of options to reduce fuel consumption

for mining trucks by 1%-5% annually,

which equates to an average annual saving

of $6,000 to $30,000 per vehicle.

The fuel-economy improvement also generates

an equivalent percentage reduction

in CO2 emissions of approximately 10

kg (22 lb) CO2 per gallon of fuel saved.

Zach Gillen, Cummins executive director–

mining business, said, “The improvements

are achieved through base engine

modifications, fuel system upgrades and

electronic calibration changes. Our technicians

will offer a tailored solution based

on the customer’s specification to achieve

the best possible savings. They are available

for Tier 1 and Tier 2 engines in service

now.”

Cummins said it is also able to reduce

engine-servicing costs through application

of the latest in air, lube, fuel,

hydraulic and water filtration technology,

along with proprietary coolants. According

to the company, field studies have

successfully validated TCO improvements

of more than 60%, extending service intervals

to a minimum of 1,000 hours.

Flanders’ Freedom Package for Haul Trucks

A leader in electric motor and drive technology,

Flanders discussed the advances

it has made with its Freedom package.

Recently, the company has expanded the

offering to haul trucks and underground

coal transporters in addition to draglines,

shovels and drills. The Freedom package

is an open-architecture control and automation

platform that allows mine operators

to integrate new components and

assemblies into a machine’s master control

system, which allows modifications to

upgrade performance.

Flanders recently completed a DC

to AC upgrade for Komatsu 830E haul

trucks operating at a coal mine in Wyoming’s

Powder River Basin. Through the

upgrade, they were able to enhance safety

with improved traction control, which

keeps the truck moving in the desired

direction even under unfavorable conditions,

such as ice, mud, snow, etc. After

the upgrade, the operators had the ability

to operate the trucks at a 33% higher topend

speed, which improves cycle times. A

new dynamic braking resistor and AC variable

speed blower motor offers increased

reliability and longer life of components.

Flowrox’s Malibu platform is a

Flowrox’s Malibu platform is a

3-D interface to equipment

such as the company’s SMART

pump sets.

The company also discussed its Invision

monitoring system that gives mines actionable

Big Data insights on the health of

its machines. Early warning systems alert

maintenance technician before issues escalate

toward catastrophic failure. By being

able to better schedule maintenance, the

system manages work orders proactively.

Flowrox Oy: Smart SolutionsmValves IIoT-Ready

Flowrox Oy’s Smart Solutions technology,

including industrial and slurry pumps and

valves equipped for the Industrial Internet

of Things (IIoT), enables “process conditions,

equipment status and performance

to be monitored on a handheld device,”

the company reported.

The Flowrox Malibu platform, a 3-D

smartware interface, connects plant performance

and equipment, such as the Flowrox

SPVE, “the first pinch valve in the world capable

of complex analytics and IIoT-ready,”

Flowrox said. “Malibu is easy to operate,

enabling access to all product-related information,

documentation, online monitoring

and preventive maintenance tools.”

Products include but are not limited to

SMART pump sets, which are equipped

with intelligent instrumentation, motor

diagnostics and controls for continuous

measurement and feedback, Flowrox

said. “SMART sleeves and other embedded

instruments provide vital information

about the operation, condition and health

of components,” the company said.

Hard-Line Highlights Teleremote Ops

Hard-Line unveiled its Teleop Auto upgrade

by featuring an Aramine LHD running

at the Norcat Underground Training

Centre in Sudbury, Ontario, live from

MINExpo in Las Vegas. Visitors to the

booth could operate the scoop remotely

from the show floor.

This upgrade provides full autonomous

driving features and can be modified to

work with any brand of machine, both new

and old, said Hard-Line Marketing Manager

Avryl Evans. The system has been

field tested at Hard-Line’s own facilities

for the last two years and now has been

tested in an actual environment with great

success, Evans said. She added that there

is a lot of interest in automation and the

company manufactures every piece of machinery

for this product.

Joy Global Unveils New Equipment and Services

Joy Global displayed the new P&H 77XD

blasthole drill, the Joy 22HD hybrid-diesel

LHD, and the Joy 4LD hard rock loader.

MINExpo 2016 also marked the commercial

launch of the P&H 2650CX hybrid

shovel. The latest rock breakers and CPAs

from Montabert were also on display, as

well as Genuine Joy service products and

consumables in the booth’s mock Service

Center. Several interactive elements al-

lowed attendees to experience other areas

of Joy Global’s product lines, including a

continuous miner simulator with Oculus

Rift technology; an augmented reality table

highlighting smart material handling

options; and a Joy longwall visualization

system with 3-D graphics.

Joy Global’s 22HD (pictured here) and the smaller 18HD are

Joy Global’s 22HD (pictured here) and the smaller 18HD are

equipped with an all-electric, smart driveline.

At an event held on the first day of the

show, Joy Global unveiled the Joy 22HD hybrid-

diesel LHD. It features the Switched

Reluctance (SR) Hybrid Drive technology

Joy Global acquired from Le Tourneau.

The 22HD and the smaller 18HD are the

first LHDs equipped with an all-electric,

smart driveline. These LHDs also feature

the new Kinetic Energy Storage System

(KESS) to enable the storage and reuse of

braking energy, reducing overall fuel consumption

by 30%. KESS supplements engine

power by more than 50% to improve

machine acceleration, reduce the effects

of engine turbo lag and dramatically improve

cycle times. The SR Hybrid driveline

is designed for more than 20,000 hours

before rebuild. The machines’ rugged

steel frames and ball and socket joints are

constructed to withstand challenging hard

rock mining applications.

The 77XD blasthole drill can be configured for diesel or electric, single- or

multi-pass, and rotary and hammer drilling.

It’s designed to deliver up to 10%

maintenance and repair cost advantage,

according to Joy Global. The 4LD hard

rock loader is a robust machine designed

to stand up to challenging narrow vein

mining conditions and provide 25% more

breakout force. The 2650CX hybrid shovel

is an innovative new machine offering

a 25% reduction in fuel consumption and

up to 15% reduction in total cost of ownership.

Miners were offered an opportunity

to operate one using a training simulator

on the stand.

Komatsu: Going Totally Autonomous

It’s difficult for vendors—at a show where

the world’s largest, most spectacular mobile

equipment is exhibited—to stand out

from the crowd, but Komatsu definitely

succeeded with the introduction of its

“Innovative Autonomous Haulage Vehicle,”

a futuristic, cabless, 230-mt-payload

rigid-body truck designed specifically

for autonomous haulage operations.

Unlike its 930E and 830E autonomous

models, Komatsu developed the

IAHV exclusively as an operator-less vehicle

designed to maximize the advantages

of unmanned operation. Komatsu said

that by eliminating the traditional operator’s

cab, distributing payload weight

equal to the four wheels when the vehicle

is loaded or unloaded, and adopting

all-wheel drive, retarder and steering systems,

the IAHV can travel equally efficient

in both forward and reverse, eliminating

the need for time-wasting K-turns and

backing at loading and unloading sites.

Komatsu also expects that this concept

will improve productivity at mines where

existing unmanned haulage vehicles face

challenging conditions, such as slippery

ground due to frequent rain/snow fall as

well as confined spaces for loading.

Komatsu’s IAHV hauler is designed to travel equally efficient in forward

Komatsu’s IAHV hauler is designed to travel equally efficient in forward

or reverse direction.

Major specifications for the IAHV include

a nominal gross vehicle weight of

416 mt; gross power output of 2,014 kW

(2,700 hp); maximum speed of 64 km/h;

turning radius of 15.9 m; external dimensions

of 15 m (length) by 8.5 m (width);

and tire size of 59/80R63. Komatsu

plans a market introduction in the near

future. A video illustrating the vehicle’s

mode of operation is available at: www.

youtube.com/watch?v=SNelRmmPpls&-

feature=youtu.be.

Komatsu also announced the commercial

release of its conventional,

400-mt-payload 980E-4 haul truck. The

980E-4, according to the company, provides

an optimal match in large-scale

mining applications with big-bucket

mining shovels (55-99 yd3) such as its

PC8000 as well as P&H’s 4100XPC and

4800XPC, loading in three to five passes,

depending on bucket size and material

density. The new truck features expanded

dump body capabilities, using high-tensile

strength and abrasion-resistant steel

materials to optimize payload capacity

while resisting damage and wear. Available

as an option, for the first time on

any of its production trucks, are Komatsu

Smart Rims, which allow easy removal

and installation of tires without removing

the rims, saving time and reducing the

impact of tire changes on downtime.

Komatsu previewed the 930E-5 haul

truck, which is scheduled for release in

the second half of 2017. The 320-mt-payload

hauler is powered by a 2,700-hp, SSDA16V160-

4 Tier 4 Final engine, offering

up to 5% less fuel consumption—yet, according

to the company, still providing a

high level of commonality between it and

Tier 2 engines. The new model also uses

DEF and SCR technology instead of mufflers for improved noise reduction.

On the shovel side, the company announced

the North American commercial

release of the PC4000-11 hydraulic mining

shovel. Best matched with 150-240

ton trucks, the -11 can be configured as a

shovel or backhoe, depending on the application.

It is powered by a Tier 4 Final,

1,875-hp, 16-cylinder SDA16V160E-3

Komatsu engine with selective catalytic

reduction (SCR) and time-saving engine

oil management systems.

Regarding Komatsu’s pending acquisition

of Joy Global Inc., Tetsuji (Ted)

Ohashi, president and CEO of Komatsu

Ltd., said, “Our customers are sharing

very positive feedback about the agreement.

Some have approached us at MINExpo

to congratulate us on our decision,”

Ohashi said. “We are working closely with

Joy Global and relevant authorities to

move the process forward.”

The companies are working to finalize

the transaction by mid-2017.

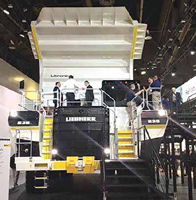

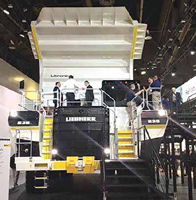

Liebherr Introduces New Equipment to North America

The motto for Liebherr’s stand was “Experience

the Progress,” and it essentially

discussed the progress the company had

made since the last MINExpo. In addition

to a new diesel engine components and

ground engaging tools (GET), the company

displayed four types of large machines:

haul trucks (the new T 236 and the T 284)

a dozer, a hydraulic excavator and a crane.

They closed a gap in the hydraulic excavator

line with the introduction of the 200-

mt class R 9200, which is designed to be

pass-matched with 140-ton haul trucks.

An electric version is available as well. The

unit on display was fitted with the Liebherr’s

advanced 12.5-m3 bucket and GET.

Liebherr says its T 236 is the first diesel electric truck

Liebherr says its T 236 is the first diesel electric truck

in class to incorporate an oil-immersed braking system

with

four-corner retarding capabilities.

The 100-ton T 236 haul truck takes

advantage of Liebherr’s electric drive

system. With its high take-off torque and

continuous power to ground capability,

the T 236 is less sensitive to grade and

payload variations. The T 236 is the first

diesel electric truck in class to incorporate

an oil-immersed braking system with

four corner retarding capabilities, providing

reliable braking technology.

The latest generation of Liebherr’s T

284 was also on display. Offering one of

the highest payloads in the industry, it

features the Litronic Plus AC drive system.

With intelligently designed systems

and components, Liebherr sees the T 284

as a platform for future advances in haul

truck technology. A special feature is its

Tier 4-ready MTU engine.

The company’s new 70-ton dozer, the

PR 776 Litronic crawler tractor, was also

on the stand. It debuted at Bauma in Munich,

earlier this year. And it is the largest

hydrostatically powered crawler tractor in

the world, according to Liebherr. After the

show, this unit will be placed into operation

at a U.S. gold mine.

This was the first MINExpo for the

company’s components division. Some of

the components and systems on the show

include a new D9812 2,700-hp diesel

engine, the new FAT 325 electric travel

drive, and a fully integrated energy storage

system for mobile and stationary applications

based on double layer capacitors.

Liebherr has also developed an advanced

software tool to minimize downtime

by maximizing troubleshooting efficiency. The Troubleshoot Advisor detects

the cause of breakdowns on mining trucks

and excavators and proposes repair procedures

according to the results of diagnostic

tests. This software is currently supporting

the service teams in 20 countries.

Modular Enhances Collision Awareness, Truck Spotting

Modular Mining Systems unveiled its

fourth generation collision awareness system,

available as a standalone product

or integrated with Modular’s DISPATCH

Fleet Management System. The new

Collision Awareness System (CAS) monitors

and notifies operators of potential

vehicle-to-vehicle collisions based on intelligent

path-prediction and pattern recognition

algorithms, helping to increase

drivers’ situational awareness when operating

heavy or light vehicles in the mine.

The system uses a high-speed, low-latency

peer-to-peer communications technology

developed specifically for safety applications

in the automotive industry.

According to the company, the system

addresses many of the most common vehicle

collision scenarios, including forward

path (front-to-rear and head-on), take-off,

speed limit violations, overtaking and intersections.

Two levels of alarms notify operators

of potential hazards; if an operator

doesn’t take corrective action after the first

notification, a more urgent, audible warning

will sound. When integrated with Modular’s

DISPATCH Fleet Management System,

alarms may be routed to the mine controller

and recorded for reporting purposes.

Modular also highlighted its new Guided

Spotting system, which employs advanced

guidance technologies, including

GPS, to assist truck operators in efficiently

spotting at load and dump locations. One

of the main benefits of the system, ac-

cording to Modular, is that it enables operators

with limited experience to match the

performance of experienced operators, facilitating

the use of more efficient loading

and spotting procedures to reclaim lost

productivity without sacrificing safety.

MTU Mining Engine Range: Totally Tier 4

Rolls-Royce’s MTU engine division displayed

a 12-cylinder MTU Series 2000

diesel engine which meets the U.S. EPA

Tier 4 emission standards. The product

portfolio includes 12 and 16-cylinder

versions of the MTU Series 2000 engine

for mining applications that cover a power

range extending from 783 to 1,163 kW

and will be available for EPA Tier 4. They

meet the U.S. standards using exhaust gas

recirculation technology (EGR), two-stage

turbocharging and common rail injection.

A 12-cylinder MTU Series 4000 engine for

EPA Tier 4 also was on display. Available

in 12-, 16- and 20-cylinder versions, this

series covers a power range from 1,150

to 3,000 kW. The Series 4000 engines,

like the Series 2000 engines, meet U.S.

EPA Tier 4 emission standards by means

of EGR, two-stage turbocharging and a

common rail injection system. Exhaust

gas aftertreatment is not necessary.

All versions of MTU’s Series 2000 engines for mining

All versions of MTU’s Series 2000 engines for mining

applications can be provided in Tier 4-compliant

emission-control configurations.

MTU noted that its ValueCare service

operators an extensive service portfolio

designed to extend the service life of engines.

ValueCare, in addition to fast response

replacement parts supply and consumables

such as coolants, engine oil and

filters, also includes maintenance contracts

designed specifically to meet the

needs and requirements of the individual

customer. MTU additionally provides remote

services to support the effective operation

of the customer’s systems and optimized

maintenance services by making

operational data and analysis available to

customers on a web-based portal.

Polydeck Goes Modular

Polydeck showcased several new screens,

including Metaldex, PanelLite, VST and

DMax. Metaldex is Polydeck’s new line

of modular AR500 steel sections in a

range of apertures that fit their PipeTop

II stringer system. This is a new product

offering the same fastening system, said

Matt Donovan, marketing manager for

Polydeck.

PaneLite is Polydeck’s lighter series

of screen panels with a strong composite

insert that reduces panel weight by nearly

2 lb/ft2, Donovan said.

Polydeck displays three new types

Polydeck displays three new types

of screening media

panels for a wide

range of applications.

VST is a dewatering panel that is specifically used in coal. This patent pending

design incorporates slots at opposing

45° angles creating a zigzag flow, which

increases retention time, providing increased

drain rates per square foot, and

reducing the amount of material getting

stopped in the panel.

DMax is Polydeck’s series of extreme

open area screen panels that utilize a

modified insert configuration that allows

more apertures. The configuration was a

slight modification to Polydeck’s existing

design, which makes it slightly weaker,

but creates more of an open area, Donovan

said.

Sandvik Upgrades the

Underground Drilling

Experience

Sandvik said it can significantly improve a

customer’s drilling experience with its new

AutoMine compatible underground drilling

offering. Based on Sandvik AutoMine

technology that has been in use for more

than 10 years in numerous underground

mines, users are now able to significantly

upgrade their operation’s productivity

and safety. The company’s range of new

intelligent rigs, led by the DD422iE development

jumbo, will soon include long

hole drills and bolters. New 3-D scanning

technology can make drilling and even

bolting more efficient by bringing in new

tools and methods for continuous quality

control. Blasting quality, overbreak and

underbreak analyses together with continuous

mine mapping increase overall drill

and blast process efficiency significantly.

Combining this with the its OptiMine

information management platform, said

Sandvik, provides a powerful tool for creating

true transparency and integration of

underground mining operations.

Sandvik’s DU412i incorporates a completely new design, taken from the

Sandvik’s DU412i incorporates a completely new design, taken from the

popular Sandvik 400 range of center

articulated, carrier-mounted ITH drill rigs.

Siemens’ Drive System Outperforms Standard

Induction Motors

Siemens’ new electric powertrain system

for underground mining vehicles, currently

in development on a 60-ton articulated

underground haul truck application, features

propulsion and auxiliary inverters,

established control hard- and software as

well as optional energy storage solutions,

the company reported.

The proton exchange membrane fuel

cell system motor (PEM Motor), typically

connected to the wheels with a planetary-

type gearbox, achieves a higher efficiency of up to 97% in operating-speed

range compared to the efficiency of standard

induction motors of similar size,

Siemens said. With these components

working together, the haul truck’s braking

energy can be intelligently harnessed and

stored for electric propulsion.

More than 1,000 Siemens mining-duty

powertrain systems are deployed globally

in the open-pit mining market, which includes

all-electric excavators and various

haul truck applications, Siemens reported.

SSAB’s Abrasion-resistant

Solutions

SSAB used MINExpo to promote its

Duroxite overlay products. By welding

chromium or complex carbides on top of

mild steel or Hardox wear plate, they have

created an extremely wear-resistant compound.

No special equipment is needed

to install Duroxite. Welding, bolting and

stud welding are the most common installation

methods. A coal operator installed

Duroxite on its discharge chute

and extended wear life from a week to six

months, and immediately noticed an improvement

in uptime.

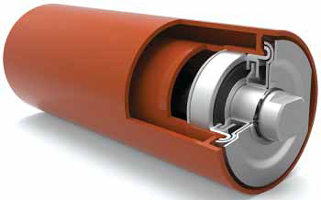

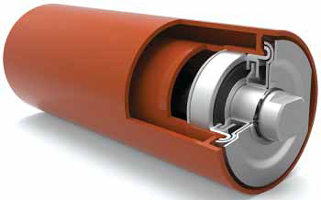

Superior’s Double Tube Roll construction gives the

idler increased rigidity for

Superior’s Double Tube Roll construction gives the

idler increased rigidity for

higher load ratings.

Superior Displays Crusher

and Conveyor Equipment

Superior Industries used MINExpo to

showcase its Patriot cone crusher, an expanded

line of mine duty idlers and its

line of Exterrra belt cleaners. With models

that range from 200 to 500 hp and production

rates up to 805 t/h (730 mt/h),

the Patriot cone crusher represents Superior’s

first foray into crushing technologies

for bulk processing applications.

Superior’s DT Idler is designed with

a ¼-in.-thick wall for added durability.

Double tube (DT) construction gives the

idler increased rigidity for higher load ratings.

This design has a 20% higher load

rating than CEMA, for improved service

life. The inner tube insulates the bearing

from vibration, reducing misalignment

and increasing the life of the bearing.

As the outer shell wears, the inner tube

maintains the structural integrity of the

roller. The DT models are available in belt

widths up to 120 in. and are equipped

with bearing sizes up to 60 mm. Superior

said it had already tested this double-

tube product line at some of the largest

iron ore mines in the world.

Designed for large mining class pulleys,

the Exterra mine-duty primary belt

cleaner solves issues associated with

maintaining constant tension as well as

installations in tight areas. Superior’s

Set For Life (SFL) technology maintains

constant, accurate tension during the

life of the blade. Operators set the tension

during installation and never have

to adjust it again. The belt cleaner’s

three-piece pole is lighter and easier to

manage during installation, especially

in tight chute applications. Additionally,

the scraper blade is segmented into 6-in.

chunks, allowing it to wear evenly.

Toyo Pumps is Now Hevvy Pumps

Toyo Pumps launched the HNS series of

submersible pumps at the show. These

products offer a fully integrated pressurized

sealing solution, the Plenum54. This

technology—creating a pump that is capable

of generating positive pressure in

the seal chamber—was three years in the

making, according to President Justin van

de Velde. According to the company, the

positive pressure technology and tailored

slurry seals make the pumps last longer

and pump more aggressive slurries than

other submersible pumps. “No one else

in the world has this,” said van de Velde.

“The real star of this show is the pressurized

seal.”

The company has also changed its

name to Hevvy Pumps and is going global,

he added.

Victaulic’s new Knife Gate Valve

Victaulic’s new Knife Gate Valve

is claimed to be

the first knife

gate valve that can be rebuilt

while

still connected.

Victaulic Valves are Rebuildable in Place

Victaulic’s new Series 795 Knife Gate

Valve is the industry’s first knife gate valve

designed to be maintained in-line without

having to remove the entire valve from the

pipeline, resulting in up to 95% savings in

downtime and more than 60% savings in

annual maintenance costs, the company

said. It is also the first installation-ready

valve made with an integrated coupling

design allowing the valve to be directly

installed on the pipe. This design reduces

labor hours, but also protects against potential

safety hazards, the company said.

“This is the first knife gate valve that

can be rebuilt while still connected,”

said Scott Sargent, product manager for

Victaulic. He added that once it’s installed,

it never has to be removed.

Michael Prince, project engineer for

Victaulic, said swapping out parts usually

takes anywhere from four to eight

hours with a normal knife gate valve, but

with their new product, this has been reduced

to 15 minutes. “They [customers]

didn’t realize maintenance could be faster,”

he added.

Victaulic also displayed the Refuse-to-

Fuse HDPE pipeline system, which it said

is simpler than traditional fusing methods—

installing up to 10-times faster,

reducing labor costs and schedule times.

The system is suitable for plain end and

grooved HDPE pipelines, and can be used

above ground, below ground and in buried

systems. Installation is easy with two or

four bolts, reducing labor time and minimizing

safety hazards. Couplings can be

readily disassembled and removed from

the pipe, and then easily reassembled.

Victaulic also now offers the latest

line of BERMAD hydraulic control and

air valve offerings to the North American

mining industry.

The design of Weir Minerals’ Trio

The design of Weir Minerals’ Trio

TP900 cone crusher

enables it to

provide a higher reduction ratio

while providing

better-shaped material.

Weir Improves Trio Cone

Crusher Performance

Weir Minerals launched the Trio TP900

cone crusher, which is part of the Trio TP

series of crushers launched globally earlier

this year. The Trio TP900 cone crusher

operates at a higher pivot point and thrower

than its predecessor, providing higher

reduction with better-shaped material, according

to Weir. This is the first machine

in this line of products, said Kurt O’Bryan,

global product manager for crushing and

screening at Weir Minerals. He believes this

will make Weir the No. 1 supplier of communition

equipment in five to 10 years.

As featured in Womp 2016 Vol 10 - www.womp-int.com