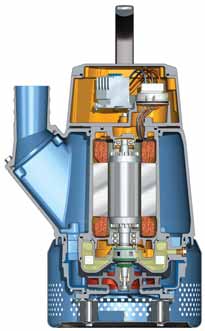

Xylem’s Flygt 2600 submersible dewatering pump has a wear-resistant closed impeller design.

The Pump-makers’ Perspective

Pumps play an essential role in mining and mineral processing. E&MJ sought the

views of two of the world’s major manufacturers on how the technology is developing

By Simon Walker, European Editor

The introduction of the rod pump for draining deep mines came hand-in-hand with the development of steam engines to power it, and the only fundamental change since then has been the marrying of the electric motor with the pump, giving better efficiency and a much more versatile system. The introduction of submersible pumps has given the miner an alternative, highly flexible approach to dewatering, although there is still the widespread need for conventional pump stations where the centrifugal pump is king.

E&MJsought expert opinion and technical insight from two of the world’s leading suppliers of pumps through a series of questions aimed at finding out their views on how the technology has developed in recent years, what the future may hold, and how mines can improve their pumps’ performance. Weir Minerals offers the Warman range of dewatering and slurry pumps as well as Multiflo pumps for dewatering. Meanwhile, Xylem’s product portfolio includes both Flygt submersible pumps and Godwin centrifugal dewatering units, giving users the opportunity to select the most appropriate system to meet their needs.

What Have Been the Main

Technological Advances

Over the Past 20 Years?

From Xylem’s perspective, the main

advances over this time-frame have been in

the areas of wear resistance and serviceability, as well as the development of

extremely high-head pumps. “To put it

bluntly,” the company said, “it doesn’t matter how efficient the pump motor and

hydraulics are if the pump doesn’t pump or

if there is no water coming out at the other

end of the hose or pipe.” By ensuring that

a pump has the highest wear resistance and

is as easy as possible to service, maximum

uptime and high efficiency are ensured.

Dewatering pumps used in mines need to be extremely robust and tough to deal with the challenging environment. Increasingly demanding conditions on site and a changed business environment where resources are limited means that customers need even more reliable and durable technologies. Greater durability means that a pump can operate at its optimum level over a longer lifetime, which keeps energy consumption at a minimum.

Today’s pumps are also much easier to maintain and service. External oil plugs and inspection chambers, which mean that pumps do not need to be opened and dismantled for simple servicing, are good examples of this. It is also now much easier to adjust the impeller. When the impeller gets worn, the pump’s performance level drops. However, by adjusting the impeller (by closing the gap between the impeller and the suction cover), full performance can be regained and the pump will operate at its best efficiency point (BEP).

Pumps are also lighter than they were 20 years ago, which makes them easier to maneuver, Xylem pointed out.

Looking at technology advances from the point of view of slurry pumping, Weir Mineralshighlighted the development of large-sized mill circuit pumps for SAG and ball mills. Flow rates have now reached up to 14,000 m 3/h with motor sizing at 4,000 kW. Weir Minerals has developed lined pumps for this application using either elastomers and/or high-chrome metals, according to the application.

How Have New Materials

Helped in This Process?

The toughest application for centrifugal

slurry pumps is in mill circuits, Weir

Mineralstold E&MJ, pointing out that one

material does not suit all applications.

Typically, for Weir Minerals’ lined pump

concept, the preference is for using rubber

liners with a metal impeller/suction throatbush combination.

There have been great strides in developing rubber formulations over the past two decades, Weir added. In the development process, some of the improved variables include determining the best performance raw materials and recipes. There has been a move from traditional physical properties to viscoelastic properties when designing rubber formulations, and there are better ways to define and understand the wear mechanisms in each component of the pump. This has helped in the development of new compound formulations for each wear mechanism, and in identifying the possible use of “dual” compounds in the slurry pump.

Weir noted that its roadmap for white cast-iron metals has headed in the direction of basic high-chrome irons with a matrix consisting of 25% (by volume) chromium carbides in 75% ferrous, with a principle hardness in the range of 600–650 Brinnell. Hyperchrome development is already at a matrix consisting of 60% chromium carbides in 40% ferrous, with a principle hardness of 750–800 Brinell. Either way, the company said, these materials clearly last longer, giving lifespan improvements of 20%–30%.

Xylem said advances in recent years have been more a result of technological developments than new materials. Hard iron and stainless steel, both used widely in pump manufacture, have been around for a long time. Improvements in dewatering pumps have resulted primarily from good hydraulic design and smart technologies that increase a pump’s wear-resistance and efficiency.

How Have You Been Able

to Make Your Pumps

More Energy Efficient?

With energy usage and efficiency becoming increasingly important in the mining

industry, E&MJasked both companies for

their views.

Weir: Computational fluid dynamics (CFD) is helping to streamline the design of impellers to fit suitable casing configurations, which enhances pump efficiency. This is sized up with the actual field performance of components to match the fitting of pump components to suit. Large mill-circuit pumps are already in the 85% best efficiency range for continuous performance.

Xylem: We have made significant strides in enhancing the energy efficiency of our pumps. For example, our Flygt 2600 drainage series features a closed impeller (not very widely used in drainage pumps), which is more efficient and wear resistant. An efficient hydraulic design, which uses less energy to move the water, is another fundamental aspect of our dewatering pumps like the new Flygt BIBO and the 2600 drainage series.

Both of those pumps feature Xylem’s DuraSpin hydraulic technology, which combines a closed impeller with a hard suction cover that sweeps abrasive particles away from the impeller neck, protecting it from wear and tear. Wear resistance means that a pump delivers a high rate of efficiency on a consistent basis, and that the performance does not drop as rapidly as for non-wear-resistant pumps.

“We find that we have been most effective in lowering mining customers’ dewatering costs when we are able to participate in the design of piping and pump controls,” Xylem said. “By consulting with a knowledgeable pump company, customers are able to get the ideal dewatering system for their projects, which will meet their needs much more efficiently without under- or over-estimating their requirements.”

What Can Operators do

to Make Their Pumps

More Energy-efficient?

Weir: Undertaking a suitable care and

maintenance program. In addition, impeller-to-suction throatbush combinations

should be regularly adjusted. If this is carried out, up to 15% more life is possible for

pump components while energy usage is

enhanced by 5%–7% in this time period.

Xylem: First and foremost, mine operators should ensure that they are using the correct pump for the job. Is the pump of the right size, capacity and power for the specific application? The size of the pipe should also be carefully considered as it will also impact energy consumption.

Pump snoring—where a pump is sucking air and emitting a “snoring” sound—is a common problem. This can wear out a pump very quickly, as well as result in a smaller volume of water being moved. Level sensors and snore controls can help to prevent this problem and keep the dewatering system operating at an optimum level. In addition, operators can employ automatic variable rpm control for both diesel- and electric-driven operations.

Regular maintenance is important to ensure that there are no glitches in the system and that energy consumption is being kept to a minimum. Our mine audits, which indicate how much can be saved in energy costs by changing to a different pump, can be a real eye-opener for customers.

What do Pump Operators

do Wrong...?

Looking at operating practice, E&MJasked

the companies if are there any specific

problems that they come across time and

time again. In other words, what are operators doing wrong—given that mining is a

tough environment for pumps?

According to Xylem, a key mistake made by some mine operators is not getting expert advice on board from the outset. Mine operators are not dewatering experts, the company pointed out, and sometimes they use whatever pump they have on hand, which may be too large or too small, leading to unnecessary cost. Bringing an expert on board at the beginning of the project will ensure that the right system is put in place, and that it operates at an optimum level throughout the lifetime of the dewatering task.

Inadequate solids handling is another common problem that can lead to snoring. Pumps can fill up with solids if the “active volume” in the sump is very low, and as a result the pump begins to snore. The active volume is the actual volume of a sump. For example, if a pump and pipe are designed for a sump volume of 5 m 3 , but as a result of solids settling only 3 m 3 is available, the pump will either empty the sump too quickly and begin to snore or suck air, or it will have to be stopped and re-started more often. Sumps can be prevented from filling up with settled solids by keeping the solids in suspension, using compact submersible mixers. Or slurry pumps (like the Flygt 5000 series) can clean a sump of the settled solids, Xylem added.

Another problem occurs where pipes and hoses are not laid out correctly—too many bends can lead to an inefficient dewatering system, which costs time and money. Xylem noted that it often sees mine dewatering operators control flows by using a manual valve instead of altering the pump speed up or down to achieve the target flow requirement.

Weir: We often see pumps where the infrastructure around the pump and basic operating procedures are not carried out competently. Examples include the orientation of the pump discharge, incorrect piping and bends layouts, insufficient space or minimum clearance on the suction side to dismantle/maintain pumps, and so on. This all leads to higher wear rates and time delays for pump maintenance.

...and What Can They do

to Overcome This?

Weir: Closer cooperation by project companies when designing pump circuits to allow

for best practice. Some customers have

signed up for service exchange programs

with Weir Minerals, which allows for optimal maintenance to pumps and improves

operating procedures. The result is longer

run time, more throughput and improved

efficiencies.

Xylem: Get advice from a dewatering expert from the outset—it will save money, time and hassle in the long run. Operators can solicit the assistance of a pumping system engineer, understand the variance in system requirements, review the pump system total life cycle cost and modify the system piping, control and so on. This can lower the total cost if the payback is achieved in an acceptable period of time.

Keep the sump clean (as outlined above) and remember that level sensors and snore controls can be very helpful in keeping a dewatering system operating at its best. A consistent program of maintenance and regularly overseeing the dewatering operation will prevent problems before they arise and ensure that water is removed as quickly as possible, so that mine operators can get on with the job of mining.

Making Pumps Easier and

Cheaper to Maintain

Across the board, a key feature of recent

developments in mining-equipment technology has been improving the ease of maintenance. After all, a drain plug or a filter that is inaccessible is likely to remain untouched,

especially if a fitter is standing ankle-deep in

cold water. Pumps are no exception.

Xylem: Simple, clean and better designs with fewer components are core features of our pumps, as they are key to making pumps easier and less costly to maintain. We have worked hard to incorporate smart, straightforward designs to our newest dewatering models, the Flygt 2600 drainage series, Flygt BIBO and Godwin NC series.

We are very conscious that customers want to be able to look after simple maintenance tasks themselves and have factored that into our new models. For example, the impeller in our new Flygt BIBO and 2600 series can be adjusted with a single screw, and both also feature an external oil plug for easy maintenance.

Weir: We like to look at the big picture. We run models on total ownership costs (TOC), which allows for comparisons in the wear life of the main wearing components, energy measure, gland water usage, downtime measurements, spare-parts holding, condition monitoring and other parameters. These days, everyone seems to be bent on buying at lower prices for capital equipment, instead of reviewing equipment on the basis of “value for money.” Cheap is not always best. Lower operating cost is the way to go.

Going Deeper Underground

With a few notable exceptions, the general

trend is that underground mines will continue to get deeper in the future. E&MJasked

the companies their views on any implications this may have in terms of pump usage,

capabilities and ensuring reliability.

Weir: As mines get deeper, the pumping equipment utilized needs to be able to generate increasingly higher heads, and the types of pumps used are generally dependent on the product handled. The total head generated by single-stage centrifugal pumps has a limitation, and for higher heads, these can be arranged in series configuration of up to six or seven pumps.

Alternatively, multistage centrifugal pumps can also be used, especially for dewatering applications. When the required head exceeds the capabilities of centrifugal pumps, another option is to use positive-displacement pumps such as piston diaphragm or hydraulic hose diaphragm pumps.

Weir Minerals can offer all these types of pumps from its Warman and EnviroTech centrifugal pump ranges and the GEHO and APEXS positive displacement pump ranges.

The APEXS range is a unique design of a positive displacement pump that transfers energy from a high pressure hydraulic power pack to the fluid being pumped using a patented Annular Pressure EXchange System, ideally suited for mine dewatering applications, the company added.

Xylem: Deeper mines will require more powerful pumps with higher head capability, and the capacity to pump liquids across greater distances. Mine planning must be undertaken at the same time as mine dewatering planning. Understanding the future of the mine will allow the pumping system engineer to make the correct decisions now, that will be able to grow with the mine in the future.

The Next 20 Years?

Pump technology is not going to stand still,

especially in an economic environment

where energy costs continue to rise. E&MJ

asked how the companies envisage pump

technology developing in the next 20

years. Will it just be a case of evolving

existing designs, or is there anything more

radical that might be possible in terms of

design and/or materials?

Xylem: As labor costs continue to rise across all markets, mines will become increasingly more mechanized. In order to compete in this changing market, mines will also need more powerful pumps that move liquids over greater distances with fewer service points. The result will be fewer pump sumps and pump stages, and higher-head pumping.

In addition, wear-resistant pumps with longer service intervals that are easy to maintain in an environment with limited labor availability will become increasingly important. Higher-efficiency motors will also be a key requirement for dewatering pumps in the future. As demands on pumps increase, we need to develop increasingly efficient technologies that can meet these demands without consuming a huge amount of energy and thus driving up costs, Xylem stated.

Weir: We believe evolving and improving existing designs together with pump materials will continue, but that the introduction of condition monitoring will be more wide-reaching. We are looking into a program of megatronics. Radical centrifugal slurry-pump designs are not expected.

Pump manufacturers are already addressing the requirements of an evolving mining industry. According to Xylem, its recent developments have focused on increasing the efficiency, durability and serviceability of dewatering pumps, with the company stating that its new Flygt BIBO offers at least three times higher uptime than a pump with a standard open impeller, as well as being one of the fastest and easiest pumps to service on the market.

With a tighter focus on slurry pumping, Weir is giving a great deal of attention to upgrading its horizontal slurry froth pumps. Tenacious froth is a problem, the company pointed out, causing unstable pumping. Centrifugal pumps do not like pumping large volumes of air, and it will be launching a new continuous air removal system for these units next year.

To summarize: ensure that dewatering and slurry-pumping requirements are part of the bigger mine plan from the start; get expert advice on pump sizes and performance; look at optimizing overall costs, not just the pump’s purchase price; and if your pump begins to snore, get in there and clean out the sump.

Kristoffer Kratz and Dwight Evans at Xylem, and Robb Clawson at Weir Minerals helped in preparing this article. Kratz is a product and application manager with Xylem, managing the development of the Flygt 2000 series of drainage pumps and Flygt 5000 series of slurry pumps. Evans is a senior applications engineer with Xylem, representing its Godwin brand. Clawson is Weir Minerals’ vice president for marketing communications, and compiled the company’s responses from colleagues in its pumps division.