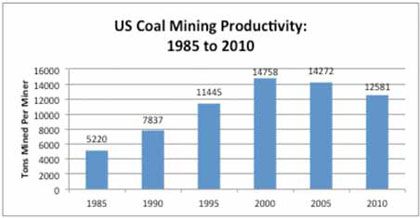

Productivity growth in the U.S. coal

industry from 1985 to 2000 was

remarkable, from about 5,200 tons/

miner per year in 1985 to almost

15,000 tons/miner per year in 2000, a

compound annual growth rate of almost

8% per year (See Figure 1). Admittedly,

some of those efficiency gains can be

attributed to the Powder River Basin’s

increasing share of production and its

scale advantage. Yet, productivity

growth of 8% is hard to ignore. What’s

equally remarkable is that this growth

occurred without any significant break-throughs in mining technology.

Everything that characterized state-of-the-art mining equipment in 2000—

from longwalls to heavy media cyclones

to high-speed rail loadouts—already

existed in 1985, although belt speeds

and haul truck capacities continued to

increase, and mines derived improved

efficiencies from technologies such as

GPS tracking and wireless communica-tion. However, productivity declined in

the first decade of the 2000s and that

is to some extent reflective of the rela-tive lack of innovation and/or the

increased regulatory environment.

That same plateauing occurred in

the sampling and analysis part of the

coal industry. There haven’t been any

breakthroughs in sampling since the

sweep-arm sampler; lab analysis equip-ment is essentially the same as it was

in 1985; and online analyzers have

experienced only incremental improve-ment as well over that time period.

However, based upon some recent field

results at a large western U.S. coal

mine, that drought in innovation may

be about to end.

Mines Need

Timely Information

In early 2010, a Powder River Basin

(PRB) mine decided it was worth the

risk to try out a new online coal analy-sis technology. Like most PRB produc-ers this mine works two areas of the pit

simultaneously. Despite the widely-held

perception that coal quality is consistent at a given PRB mine, there can be

enough variation, especially in today’s

highly competitive market, to warrant

an online analyzer to monitor and

respond to real-time trends.

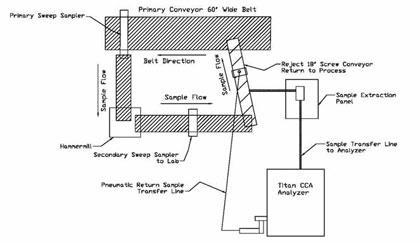

This mine has two adjacent truck

dumps from where the coal is trans-ported directly to the four loadout silos

by a 60-in. conveyor at rates of 3,000

to 6,000 t/h. A two-stage sweep-arm

sampling system is installed on this

belt to determine the coal quality enter-ing the silos. Physical samples are

taken every three to four hours and sub-jected to both quick and ASTM analy-ses. The quick analysis results (sulfur,

ash, moisture and Btu/lb) are available

approximately three hours later. The

ASTM results arrive up to 24 hours

after the sample was taken. For the

mine to respond to even the quick

analysis, it is reacting to data that is on

average almost five hours old.

The need for online analysis was

clear. Not only could a coal analyzer

provide prompt coal quality data to pit

operations for corrective action, it could

also give the control room operator

advance warning of impending prob-lems in satisfying the contract specs of

an upcoming train. Moreover, not only

was the quick lab analysis not really all

that quick, it also failed to include an

analysis of the Na2

O fraction in the ash,

itself a criterion for rejecting a train.

A New Solution

The new online analyzer that this mine

decided to test could not only detect

the low levels of Na

2

O that other online

analysis technologies cannot, but it

could also measure moisture directly,

without having to make any assumption

of bound moisture levels, as microwave

moisture meters must. The analyzer

itself operates on a sample stream;

hence, the logical location for the unit

was in the vicinity of the existing sam-pling system, where a sample could be

routed to the analyzer. (See Figure 2).

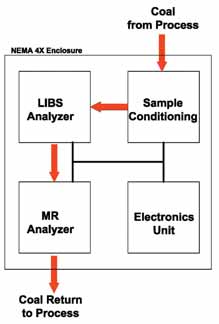

There are actually two technologies

deployed in the Progression Titan CCA:

Magnetic Resonance (MR) and Laser

Induced Breakdown Spectroscopy

(LIBS). MR has always held promise for

online moisture measurement; the chal-lenge was designing an analyzer that

could incorporate an analysis chamber

small enough for MR to operate. The

Titan CCA does just that with its 1.2-in.

diameter analysis chamber. The use of

LIBS for online elemental analysis was-n’t entirely new, with an Israeli compa-ny having done trials in South Africa a

few years ago without commercial suc-cess. The Titan CCA’s LIBS analysis, in

contrast, has shown excellent ability to

do elemental analysis.

Magnetic Resonance operates by the

rapid application and removal of Radio

Frequency (RF) electrical pulses within

a magnetic field. The technology is

equivalent to receiving a full body MRI

at a hospital—the difference being the

analyzer returns spectroscopy data

while the hospital MRI returns images.

This phenomenon provides precise

hydrogen proton measurements leading

to very accurate moisture measurement

and hydrogen proton inputs into the

calorific value determination.

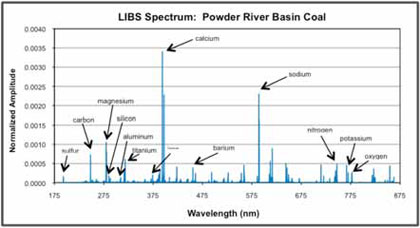

LIBS operates by focusing a laser

into a second analysis chamber and

analyzing the spectrum of the vaporized

material (See Figure 3).

Not only can LIBS achieve accura-cies comparable to those of other ele-mental analysis technologies (primarily

PGNAA) for sulfur and the six major ash constituents (Si, Al, Fe, Ca, K and Ti),

but it also can measure Na and Mg,

which PGNAA cannot in most coals.

This in turn leads to better ash fusion

determination and more accurate base-to-acid ratio estimation.

Progression is anything but a novice

to these technologies. They have been

successfully supplying the petrochemi-cal market with MR technology for more

than 20 years. In 2004, the company

began working with some of the world’s

most knowledgeable LIBS experts in

the fields of space exploration, mining

and materials handling and government

labs. In that same year, Progression

first tested a commercial LIBS analyzer

on an over-the-belt configuration within

the minerals industry and today has

multiple MR systems operating within

the phosphate industry. The years of

real-world applications experience in

the mining industry contributed signifi-cantly in the development and design of

the Titan CCA.

The Titan CCA combines both tech-nologies in a single instrument, with

adjacent analysis modules for MR and

LIBS (See Figure 4).

The small footprint (64-in. wide by

24-in. deep) coupled with mechanical

conveying to the analyzer and pneumat-ic transport of sample streams from the

unit minimizes installation problems.

Considering that the unit operates on

minus 4 mesh sample streams, this ana-lyzer is most likely to be found in load-out towers, accepting either secondary or

tertiary reject streams.

The PRB mine discussed in this arti-cle actually tried out a prototype device

from Progression in 2010 and then

opted for a full production unit in the

fall of 2011. For a view of the installed

Titan CCA, see Figure 5.

As is typical of any established tech-nology being applied to a new market,

there were some teething problems dur-ing commissioning. These issues, asso-ciated with a reliable air supply to the

unit, coal sampling, and network con-nectivity had been satisfactorily

addressed by early 2012. The unit has

been running reliably since then.

The PRB mine with the Titan CCA

uses it in both feedback and feed-for-ward modes. They use a rolling average

of online analysis results to detect trends in sulfur, ash, moisture, Btu/lb

and Na2O ash fraction, and ascertain

whether any of the contract specs are at

risk. If they are, a team makes a quick

mitigation decision that may consist of

either guidance to the shovel operators

or in extreme cases reassigning one or

more haul trucks to the higher quality

location. In addition, the control room

operator tracks the silo qualities in real

time, looking for any trends that might

threaten a contract limit. He, too, can

direct a mitigation response, to restore

a cushion in coal quality vis-à-vis con-tract limits.

There are tangible benefits that the

analyzer brings to the mine. With the

analyzer, the mine has increased its

ability to communicate with the pit pro-duction operators and troubleshoot

quality variances, and they can more

readily respond to adverse quality

trends not apparent from the core data.

Having coal quality information on a

real-time basis is especially critical

when the mine is loading trains back to

back, in order to avoid backing up rail

traffic or losing a train altogether.

Analytical Results

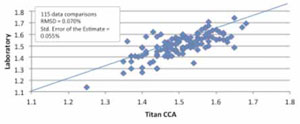

Inasmuch as the mine already had a

two-stage sampling system on the silo

feed belt, lab vs. analyzer comparisons

for performance assessment were

straightforward. Performance data from

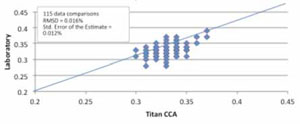

a three-week period in February 2012-March 2012 showed that the Pro-gression unit was outperforming other

elemental analyzers particularly in

calorific value and moisture, and of course in Na2

O as well, since PRB sodi-um levels lie below the detection

threshold for PGNAA analyzers.

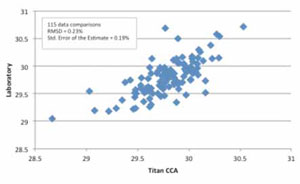

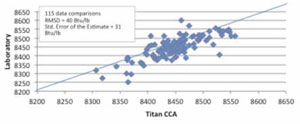

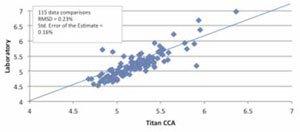

Comparisons between the laborato-ry and the analyzer on three to four hour

batches on moisture, calorific value,

ash, sulfur and sodium are shown in

Figures 6a-6e.

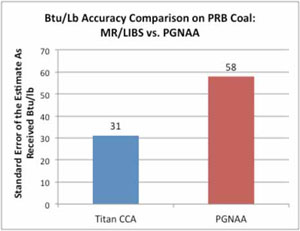

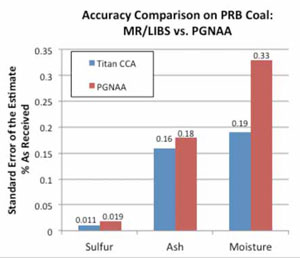

Figures 6f and 6g draw a compari-son between the performance of the

Titan CCA analyzer and another analyz-er using PGNAA technology, also on

PRB coal. The PGNAA data was taken

from a published document from anoth-er analyzer supplier.

Summary

The coal industry has made great

strides in productivity over the past

quarter century, but it has done so pri-marily without the benefit of any major

technological or significant design

improvement in mining equipment.

Mining efficiency gains have been

largely of the incremental variety, as

opposed to step jumps. This has been

especially true with online analyzers.

However, there now appears to be an

innovative pair of technologies found in

a single instrument from Progression

Inc. that could be the process control

breakthrough the market has been wait-ing for.

Richard Woodward is a consultant,

specializing in online coal analysis,

www.woodward-consulting.com