Giving the necessary attention to the drill string will lead to lower operating costs.

Optimizing the Rotary Drill String

In rotary drilling, careful selection of drill string components is vital to achieve accurate

holes, optimal rock fragmentation and operational efficiency—parameters that

affect total operational costss

By Rick Meyer

The primary purpose of the drill string

is to transmit the rotational torque and

weight from the power source—the rotary

head of the rig—to the rockbreaking drill

bit. As with every rock drilling method,

the power must be transmitted as efficiently

as possible, and return as few

vibrations as possible, as these cause

unnecessary wear on the rig and reduce

penetration rates. When selecting components

for the drill string, attention must

be given to the different roles of the support

tools in the string. The aim can be to:

• Absorb damaging vibrations traveling

back up the drill string;

• Improve transmission of energy from

the rotary head to drill bit;

• Centralize the drill bit within the hole;

• Achieve longer bit life;

• Reduce friction as the drill string

passes through the drill rig deck;

• Stabilize the hole wall to prevent hole

caving;

• Increase penetration rates and lower

drilling costs;

• Achieve blast hole accuracy for improved

blasting efficiency; and

• Improve the end result—the fragmentation

of the blasted rock.

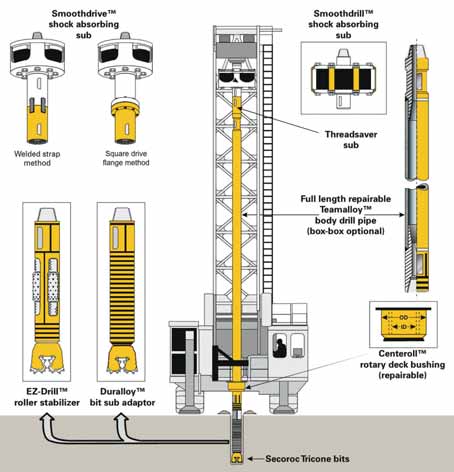

At the very top of the drill string, between the rotary head and drill pipe, a shock absorber is commonly used. As the name indicates, the intention of this tool is to reduce the negative effects of harmful vibrations that travel back up the string as a result of the drilling process.

The benefits of using a shock absorber

include:

• Improved torque control;

• Increased drilling penetration rates;

• Better drill rig availability and extended

drill rig drive head and mast life; and

• Longer service life of drill bits.

To guide the drill string and reduce the risk of wobbling, a rotary deck bushing is used at the drill rig deck opening. The deck bushing guides the pipes to prevent reduction of rotary head torque and assists with the final straightness of the hole.

The deck bushing contains an outer housing with a top flange that allows it to fit perfectly into the deck opening. A series of roller bearings allow the inner sleeve to rotate with the drill string. Wear of the deck bushing occurs primarily on the inner sleeve as cuttings are blown upward, between the drill pipe and the inner sleeve.

The role of the drill pipe is to transfer sufficient amounts of rotational torque and weight to the drill bit. The goal is to establish an optimal rate of penetration while still achieving an acceptable life of the tricone bit. The use of strong and straight alloy drill pipe is one of the best ways of preventing wobbling of the drill string and hole deviation. Drill pipe is subjected to a severe and abrasive environment, due to the rapid evacuation of drilling cuttings through the annulus of the hole, causing a sandblasting effect on the drill pipes. It is logical, therefore, to use only the best alloy steel for both the threaded connections and the body of the drill pipe. Special wear protection material is applied to the most critical areas of erosion at the bottom of the drill pipe. The drill pipes can, in most cases, be refurbished to prolong service life.

All in all, considering the significant amount of capital invested in a rotary blasthole drill rig and the annual investments in tricone drill bits, the selection of the best quality rotary drill string tools that are suited to the application is critical to the success of the drilling program. The rotary drill string tools should not just be considered as mere support tools, but rather as an essential, integrated part of the total rotary drilling system.

The following basic criteria should

be considered when deciding which

rotary drill string tools will best optimize

overall drilling performance and cost

effectiveness:

• Are quality materials and innovative

design used to address specific drilling

problems?

• Can the tools be refurbished for an

economical second run?

• Does the tool supplier offer application

and follow-up service?

In conclusion, straight blast holes drilled exactly to the pre-planned hole bottom positions pave the way for lower total operating costs, taking into account the entire process: drilling, blasting, secondary breaking, loading, haulage and crushing/screening.

Meyer is the business development manager with Atlas Copco Thiessen, located in Langley, B.C., Canada. He can be reached at 604-514-5765 or E-mail: rick.meyer@ca.atlascopco.com