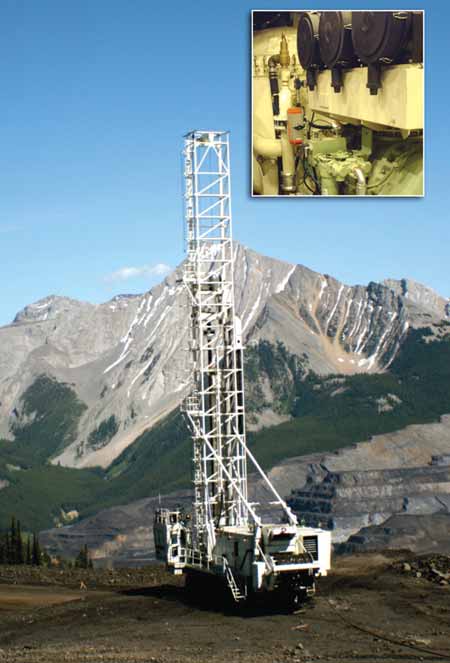

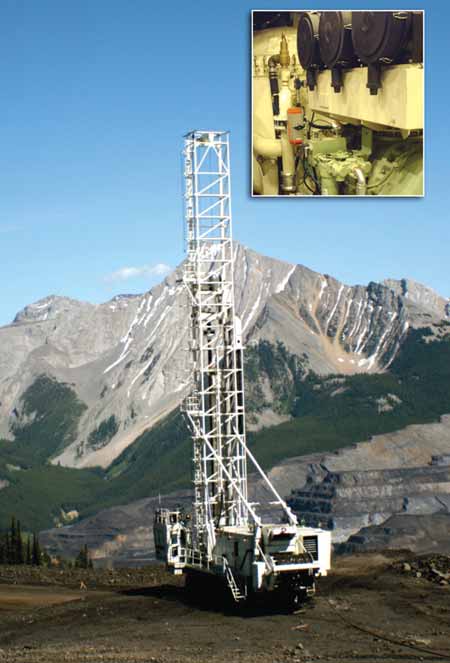

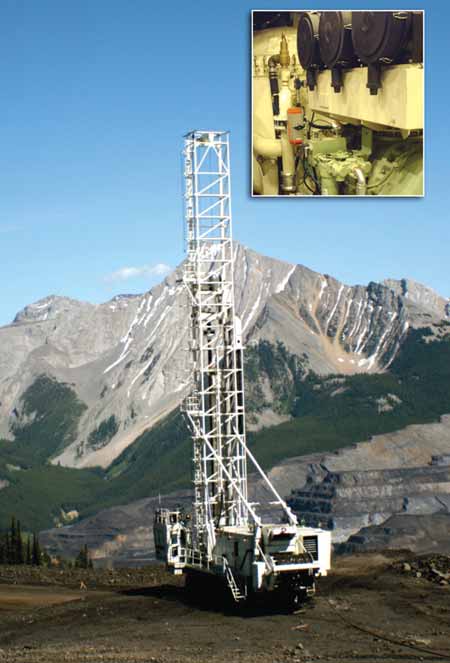

Higher Capacity Drill Air Compressor Improves High-Altitude Performance

Bucyrus 49HR drill equipped with 3,800 cfm (107 m3/m) air compressor (inset).

Bucyrus 49HR drill equipped with 3,800 cfm (107 m3/m) air compressor (inset).

www.bucyrus.com

As featured in Womp 2009 Vol 09 - www.womp-int.com