Osisko Mining received Quebec government

authorization in late August 2009 to

complete development of its Canadian

Malartic open-pit gold project and is proceeding

with construction of the mine and

mill. Construction is expected to take 18

months, and the project is planned to be

fully operational by the second quarter of

2011. Production is planned to average

591,000 oz/y of gold over 10 years of operation

based on current proven and probable

reserves of 6.28 million oz and will exceed

600,000 oz/y in the initial years of operation.

Production costs of $319/oz will be in

the lowest quartile of world gold producers.

In addition to current reserves,

Canadian Malartic’s measured and indicated

resources stand at 3.6 million oz, and

inferred resources total 720,000 oz. Five

mineralized zones outside the planned pit

and additional targets are currently being

explored by six diamond drills. Drilling during

2009 will total about 200,000 m.

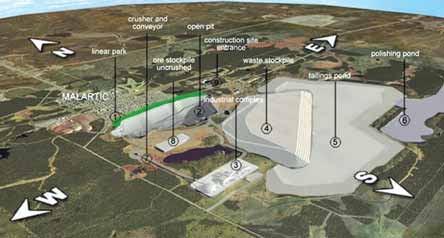

The Canadian Malartic mine is located

at the southern edge of the town of

Malartic, and mine development required

movement of a neighborhood to make way

for mining operations. This aspect of the

project was 98% complete as of

September 2009. Drilling and blasting

activities have been designed to control

blast induced vibrations and airblast overpressure

on the town.

With overall investment of nearly C$1

billion, the Canadian Malartic project will

create about 800 direct jobs during construction

and 465 permanent direct jobs

during the 10 years of operation. A large

majority of the new jobs will be taken by

residents of the town of Malartic and the

Abitibi-Témiscamingue region.

Canadian Malartic mine planning is

based on an ore resource of 183.3 million

mt at an average grade of 1.07 g/mt gold.

Mine production will total 150,000 mt/d of

ore and waste, and the mill will process

55,000 mt/d of ore. Access to the pit will

be via a 35-ft-wide, 10% decline ramp

designed to accommodate Caterpillar

793F haul trucks. The haulage fleet initially

will include 12 units and is planned

to increase to 22 units by the sixth year of

operation due to the deepening of the pit

and higher dump levels for waste.

Two 28-m3 O&K RH340-B hydraulic

shovels will load ore and waste. During the

second year of operation, a 21-m3 O&K

RH200 hydraulic shovel will be added to

increase the mining rate from 51 million

mt/y to 64 million mt/y. A Cat 994F HL

front-end wheel loader will complement the

shovels and re-handle ore from the stockpiles.

Ancillary equipment will include two

Cat 16 M graders, four track-type Cat D10T

dozers, one Cat 834H wheel dozer, two

water trucks, and other support equipment.

The processing flowsheet includes gyratory

crushing and SAG and ball mill grinding.

Cyclone overflow from the tertiary

grinding circuit will be thickened to about

50% solids and fed to a leach tank circuit,

where oxygen will be injected to increase

the kinetics of the dissolution of gold in the

leach circuit. This slurry will flow by gravity

to two parallel sets of carbon-in-pulp

(CIP) pump cell carousels, where activated carbon will absorb the gold in a countercurrent

flow arrangement.

The loaded carbon will be screened

from the slurry and transferred to the stripping

circuit, where the gold will be

stripped into a gold pregnant solution and

deposited in the form of a sludge onto

stainless steel cathodes. The deposited

gold sludge will be pressure washed to the

bottom of the electrowinning cells and

subsequently filtered, dried, and poured

into gold doré bars.

The stripped carbon will be reactivated

in two kilns and re-used in the carousel

pump cell CIP circuit. The slurry from the

last stage of the tank series in the

carousels will be barren in gold and will be

directed to the tailings thickener.

The original Canadian Malartic deposit

was discovered in 1926, and underground

mine production started in 1935. The

mine closed in 1965 after producing

1,076,000 oz of gold from 9.93 million mt

of ore grading 3- to 6-g/mt gold. Osisko

acquired the property in 2004.

As featured in Womp 2009 Vol 08 - www.womp-int.com